Manganite/metalloporphyrin compound layered sandwich nanometer material suitable for electrocatalysis water oxidation

A metalloporphyrin, manganese oxide technology, applied in the direction of organic compound/hydride/coordination complex catalyst, chemical/physical process, physical/chemical process catalyst, etc., can solve the problem of limited application, poor cycle performance, electrical conductivity low problems, to achieve the effect of low price, simple process and no pollution, and improved electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

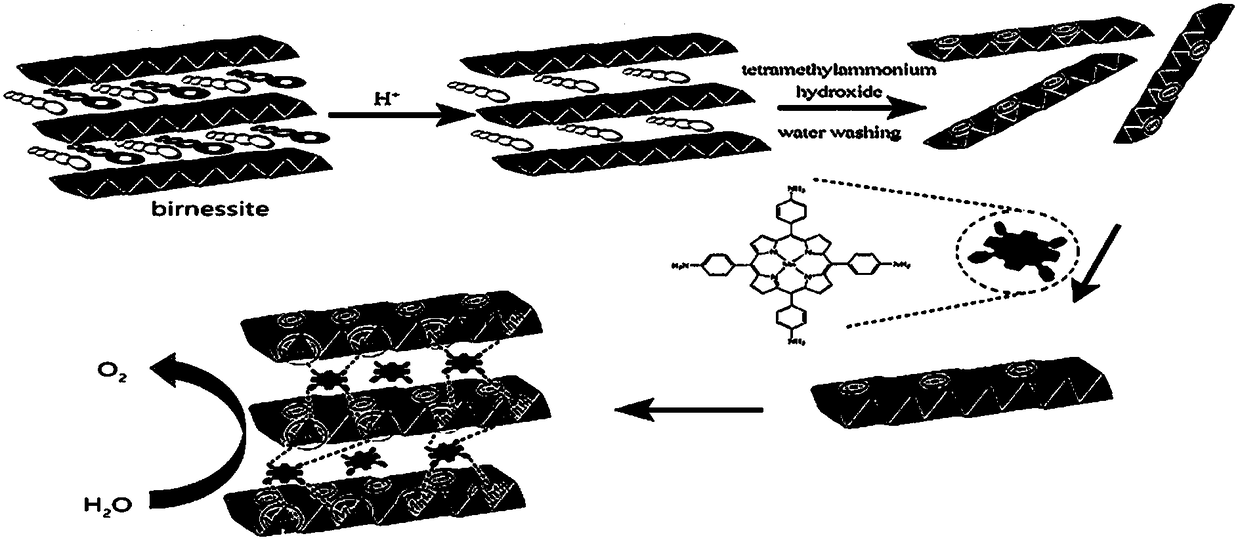

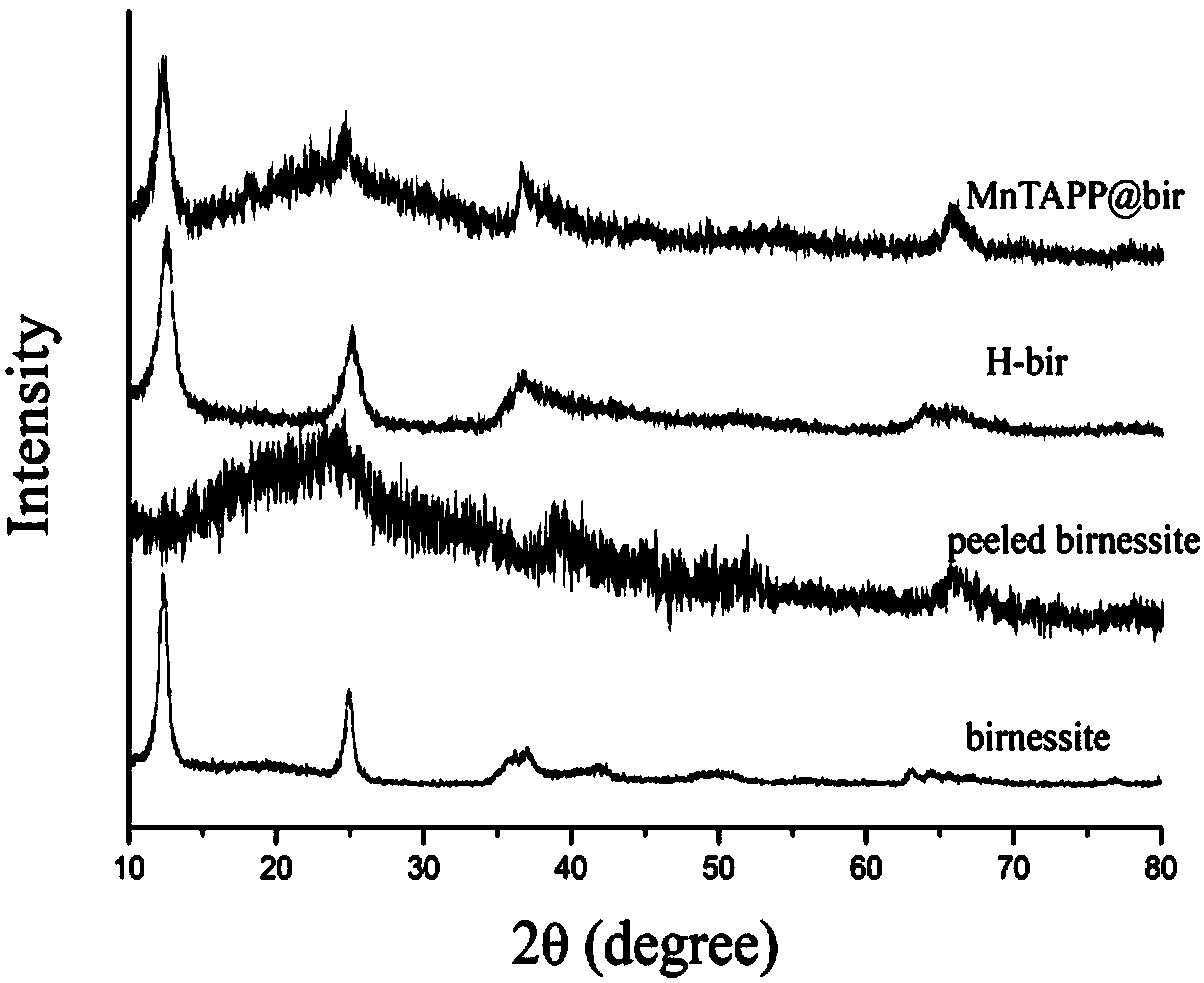

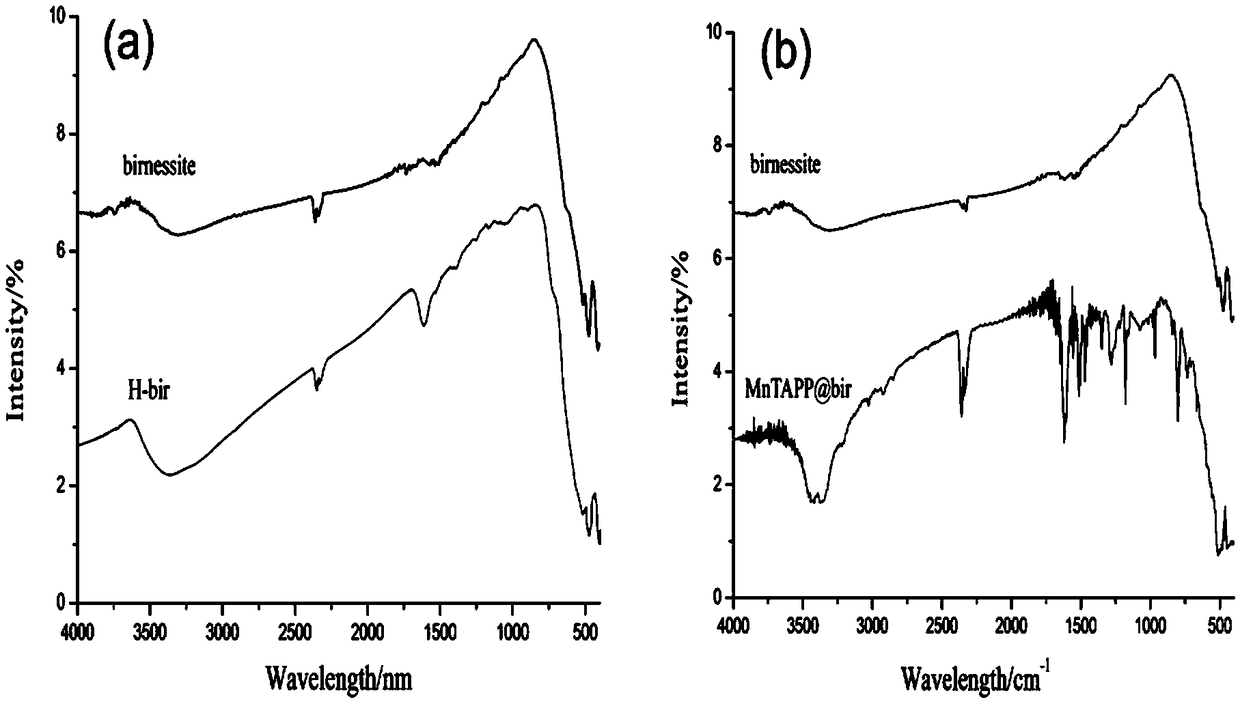

[0027] Weigh 1.35g MnSO 4 ·H 2 O and 3.0EDTA-2Na were dissolved in deionized water and stirred for 30 min to obtain a white suspension solution called Sa. Dissolve 1.2g NaOH in 50ml deionized water and stir until completely dissolved, called Sb. Under rapid stirring, slowly drop Sb into Sa, continue to stir for 2 hours after the dropwise addition, filter the precipitate, wash with deionized water several times, and then place it in a vacuum oven at 40°C for 12 hours to finally obtain the birnessite type δ -MnO 2 The test results of powder (XRD, IR, SEM are respectively as figure 2 , image 3 , Figure 4 ). Weigh 2g of birnessite type δ-MnO 2 with 300ml 1mol / L HNO 3 The solution was mixed and stirred at room temperature for 12 hours, filtered with suction, washed to neutrality, dried at 70°C, and ground to obtain acidified birnessite-type δ-MnO without alkali metal ions 2 (XRD, IR test results such as figure 2 , image 3 ). Weigh 1g of birnessite-type δ-MnO after ...

Embodiment 2

[0030] Weigh 2.7MnSO 4 ·H 2 O and 6.0 EDTA were dissolved in deionized water and stirred for 30 min to obtain a white suspension solution called Sa. Dissolve 2.4g KOH in 50ml deionized water and stir until completely dissolved, called Sb. Under rapid stirring, slowly drop Sb into Sa, continue to stir for 2 hours after the dropwise addition, filter the precipitate, wash with deionized water several times, and then place it in a vacuum oven at 40°C for 12 hours. The final product: birnessite Type δ-MnO 2 powder. Weigh 4g of birnessite type δ-MnO 2 Mix with 300ml 2mol / L HCl solution, stir at room temperature for 8 hours, filter with suction, wash the precipitate to neutrality, dry at 70°C, grind, and finally obtain acidified birnessite-type δ-MnO without alkali metal ions 2 . Weigh 1g of birnessite-type δ-MnO after acidification 2 , disperse it in 120ml of deionized water, then add 30ml of tetraethylammonium hydroxide, stir at room temperature for 48h, centrifuge the mixed...

Embodiment 3

[0034] Weigh 3.2MnSO 4 ·H 2 O and 4.8 sodium citrate were dissolved in deionized water, and stirred for 30 minutes to obtain a white suspension solution, called Sa. Dissolve 2.9g LiOH in 50ml deionized water and stir until completely dissolved, called Sb. Under rapid stirring, slowly drop Sb into Sa, continue to stir for 2 hours after the dropwise addition, filter the precipitate, wash with deionized water several times, and then place it in a vacuum oven at 40°C for 12 hours. The final product: birnessite Type δ-MnO 2 powder. Weigh 2g of birnessite type δ-MnO 2 with 300ml 1mol / L HNO 3 The solution was mixed and stirred at room temperature for 12 hours, filtered with suction, washed to neutrality, dried at 70°C, and ground to obtain acidified birnessite-type δ-MnO without alkali metal ions 2 . Weigh 1g of birnessite-type δ-MnO after acidification 2 , dispersed it in 120ml of deionized water, then added 20ml of triethanolamine, stirred at room temperature for 72h, centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com