Kitchen garbage cleaning equipment and method

A technology of kitchen waste and cleaning equipment, which is applied in the direction of chemical instruments and methods, solid waste removal, organic fertilizers, etc., can solve the problems of increasing the difficulty of pollution treatment, human health hazards, pollution, etc., to improve the cleaning effect and reduce The effect of clearing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

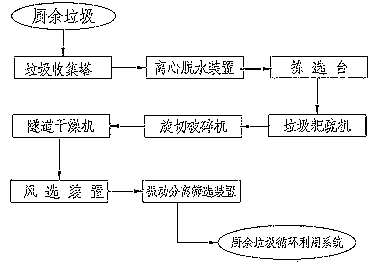

[0042] A kitchen waste cleaning equipment, including a garbage collection tower, a centrifugal dehydration device, a sorting table, a garbage rake machine, a rotary cutter, a tunnel dryer, a wind separation device, a vibration separation and screening device and a frame, a conveyor belt, and a hoist , cleaning device, garbage shoveling device and power equipment;

[0043] The collected kitchen waste is unloaded into the garbage collection tower, and the large pieces of garbage, packaging bags and packaging ropes are minced by the horizontal axis rotary tiller cutter of the garbage collection tower, and then passed through the screw extrusion device at the exit. Squeeze out the water in the garbage when outputting the garbage, input it into the garbage centrifugal dehydration device to remove the clear water, and spread it on the garbage conveyor belt; through the intelligent manipulators set on both sides of the garbage conveyor belt and controlled by artificial intelligence, p...

Embodiment 2

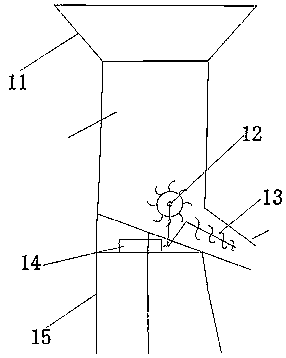

[0045] A garbage collection tower used by the kitchen waste cleaning equipment in Embodiment 1, including a hopper, a tower cavity, a horizontal axis rotary tiller cutter located at the inner bottom of the tower cavity, a garbage outlet channel, and a screw extrusion device located in the channel , Bracket 1; the bottom of the tower cavity is inclined towards the garbage outlet channel, the horizontal axis rotary tiller cutter is placed horizontally on the inner side of the garbage outlet channel, the screw extrusion device is located in the garbage outlet channel, and the support frame is arranged at the bottom of the tower body; The sewage squeezed out from the garbage outlet channel is discharged into the sewage pool to be treated through the sewage pipe.

Embodiment 3

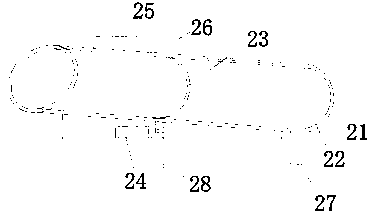

[0047] A garbage centrifugal dehydration device used in the kitchen waste cleaning equipment of Embodiment 1, including an outer cylinder, a dehydration drum, a timing belt, a cleaning device, a sewage pipe, a centrifugal drive device and a bracket 2; the dehydration drum is placed in the outer cylinder , the surface of the inner wall of the dehydration drum is rough, and water filter holes are set on the wall of the drum; the spray pipe of the cleaning device is placed between the outer drum and the wall of the dehydration drum; the sewage pipe is arranged at the inner bottom of the outer drum; the timing belt is arranged outside the middle of the dehydration drum; The kitchen waste output from the garbage collection tower enters the dehydration drum, and the dehydration drum is driven by the driving device and the synchronous belt for centrifugal dehydration, and the sewage is discharged from the sewage pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com