An in-situ oriented non-oxide reinforced silicon carbide brick and its preparation method

A non-oxide, silicon carbide brick technology, applied in the field of silicon carbide bricks, can solve problems such as damage, achieve the effect of improving the degree of progress, improving strength and toughness, and eliminating the difference in the degree of nitriding reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

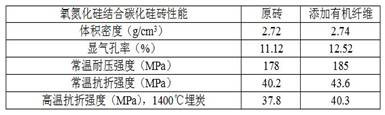

Embodiment 1

[0029] A total of 70 parts of 98 silicon carbide particles (20-30-20), 15 parts of 98 silicon carbide fine powder 325 mesh, 10 parts of 98 metal silicon 240 mesh, 5 parts of 98 metal silicon 400 mesh; plus dextrin binder 3%; added organic fiber is 0.2%, diameter 30μm, length 4mm;

[0030] The preparation method is:

[0031] Step 1. Mixing sequence: all powders and antioxidants are pre-mixed for later use. Add aggregate to the wheel mill and dry mix for 5 minutes; add binder and dry mix for 5 minutes; add water and mix for 5 minutes; add powder and mix for 20-30 minutes; finally use 0.5mm sieve to sieve the organic fiber into Mixer, after all sieved in, continue to mix for 5 minutes and discharge;

[0032] Step 2, forming process; the forming process adopts normal pressing forming, pours the mixed material into the mold, and forms under a certain pressure; adopts friction brick press, hydraulic press or manual pounding to form;

[0033] Step 3: After drying the green body at...

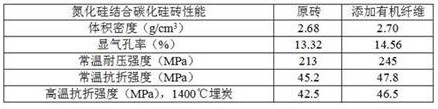

Embodiment 2

[0037] 68 parts of 98 silicon carbide particles in three particle sizes (20-30-20), 7 parts of 98 silicon carbide fine powder 325 mesh, 10 parts of 98 metal silicon 240 mesh, 5 parts of 98 metal silicon 400 mesh; 5 parts of silicon dioxide fine powder Parts, plus 2% calcium lignosulfonate binder; the added organic fiber is 0.2%, with a diameter of 30μm and a length of 4mm;

[0038] The preparation method is:

[0039] Step 1. Mixing sequence: all powders and antioxidants are pre-mixed for later use. Add aggregate to the wheel mill and dry mix for 5 minutes; add binder and dry mix for 5 minutes; add water and mix for 5 minutes; add powder and mix for 20-30 minutes; finally use 0.5mm sieve to sieve the organic fiber into Mixer, after all sieved in, continue to mix for 5 minutes and discharge;

[0040] Step 2, forming process; the forming process adopts normal pressing forming, pours the mixed material into the mold, and forms under a certain pressure; adopts friction brick pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com