Method for preparing 3-hydroxypropionaldehyde through hydration of acrolein

A technology for hydration of acrolein and hydroxypropionaldehyde, which is applied to the preparation of carbon-based compounds, preparation of organic compounds, chemical instruments and methods, etc., and can solve the problems of unsuitable continuous operation, low production efficiency and long reaction time of tank reactors and other problems, to achieve the effect of reducing the activation energy of the reaction, high production efficiency, and increasing the probability of effective collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

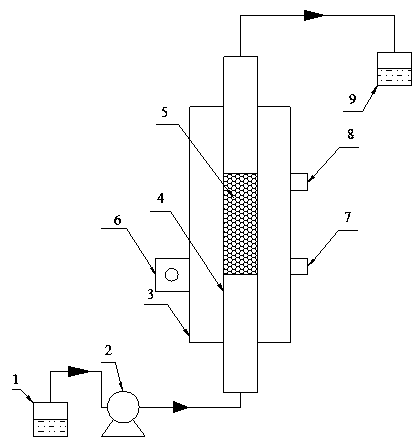

[0024] Such as figure 1 30 g of polystyrene-based chelating ion resins were packed into the fixed-bed reactor 4 to form a catalyst bed 5 . Turn on the microwave and set the power to 50 W, use the metering pump 2 to pump the acrolein aqueous solution with a mass fraction of 15% in the raw material tank 1 into the fixed bed reactor 4 from bottom to top, and the space velocity is 5 h -1 , in the acrolein aqueous solution, add the hydroquinone of 500ppm by mass as the polymerization inhibitor, the first temperature sensor 7 and the second temperature sensor 8 record the catalyst bed layer 5 feed end and the discharge end in the fixed bed reactor 4 The temperatures are 45°C and 55°C respectively (the first temperature sensor 7 and the second temperature sensor 8 both use optical fiber sensors), and the average temperature of the reaction raw materials flowing through the catalyst bed 5 is 50°C. While the temperature on the top gradually increases successively, the mass concentrati...

Embodiment 2

[0026] Embodiment 2: as attached figure 1 As shown, 30 g of polystyrene-based chelating ion resins are loaded into the fixed-bed reactor 4 to form a catalyst bed 5 . Turn on the microwave and set the power to 30W, use the metering pump 2 to pump the acrolein aqueous solution with a mass fraction of 18% in the raw material tank 1 into the fixed bed reactor 4 from bottom to top, and the space velocity is 3.8 h -1 , adding 300 ppm by mass of 2,2,6,6-tetramethyl-4-hydroxypiperidine nitroxide free radicals in the acrolein aqueous solution as a polymerization inhibitor, the first temperature sensor 7 and the second temperature sensor 8 measured The temperatures at the feed end and discharge end of the catalyst bed 5 in the fixed bed reactor 4 are 37°C and 43°C respectively (the first temperature sensor 7 and the second temperature sensor 8 both use optical fiber sensors), and the raw material flows through the catalyst bed 5 with an average temperature of 40°C.

[0027]The reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com