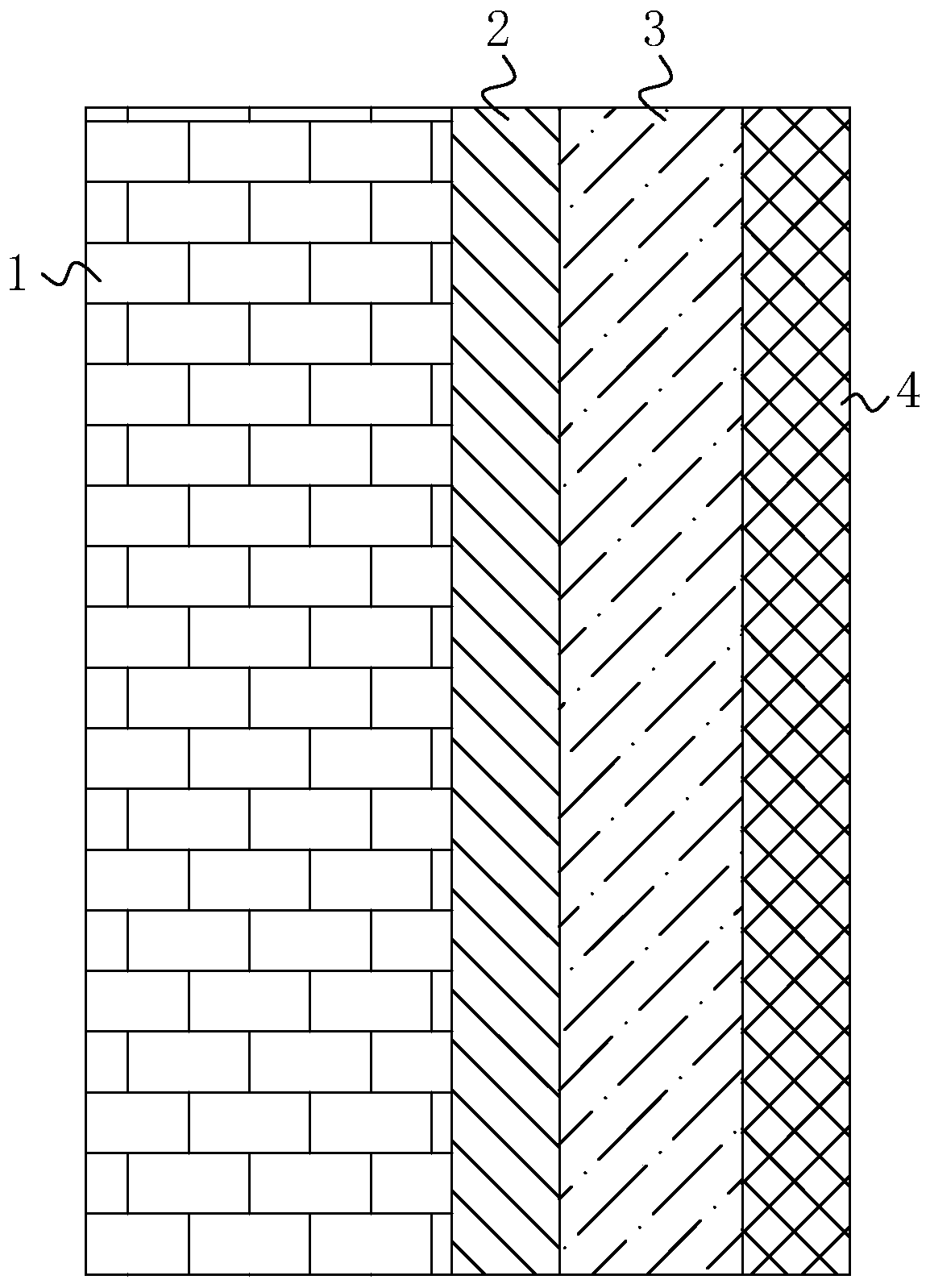

A thermal insulation coating and its preparation method and thermal insulation system using the coating

A thermal insulation and coating technology, applied in thermal insulation, antifouling/underwater coatings, reflective/signal coatings, etc., can solve the problems of thick coating, unsuitable building exterior wall finish, etc., to achieve bond strength High, increase the suspension stability, the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

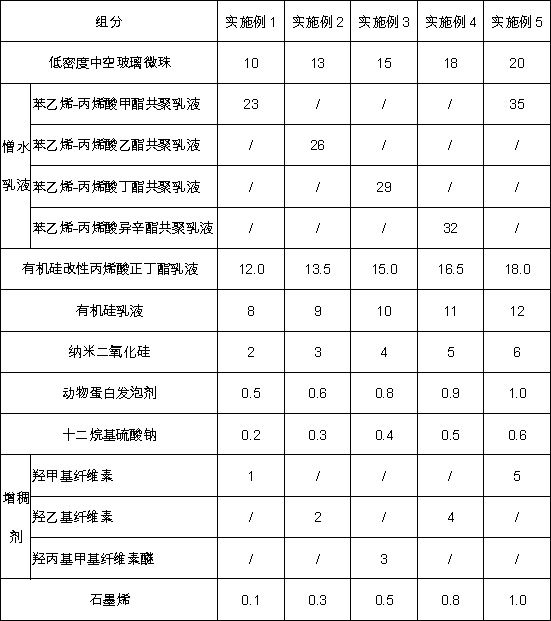

[0055] A kind of thermal insulation coating, by weight, the content of each component in embodiment 1-5 is shown in the table below:

[0056] Table 1. Each component content table of embodiment 1-5

[0057]

[0058] Among them, the bulk density of low-density hollow glass microspheres is ≤1g / cm 3 ;Animal protein foaming agent can be replaced with vegetable protein foaming agent. The concentration of the silicone emulsion used in Examples 1-5 is 1% (w / w), 2% (w / w), 3% (w / w), 4% (w / w), 5% (w / w) w).

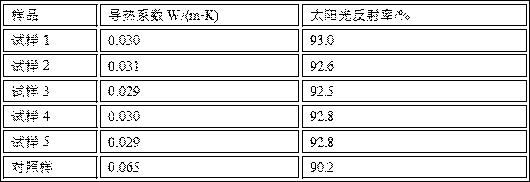

[0059] Performance Testing

[0060] The thermal insulation coatings of Examples 1-5 were used as samples 1-5, and the commercially available reflective thermal insulation coatings were used as reference samples, referring to GB / T10295-2008 "Steady-state thermal resistance and related characteristics of thermal insulation materials for determination of heat flow Measurement Method", JG / T517-2017 "Hollow Glass Bead Thermal Insulation Materials for Engineering" and JC / T1040-2007...

Embodiment 6

[0065] A preparation method for thermal insulation coating, which comprises the steps of:

[0066] P1. In parts by weight, 23 parts of styrene-methyl acrylate copolymer emulsion, 12 parts of silicone-modified n-butyl acrylate emulsion, 8 parts of silicone emulsion with a concentration of 1% (w / w) and 0.1 part of graphite Add alkene into the stirring tank, stir and mix at a speed of 500r / min to obtain a mixed material 1;

[0067] P2. In parts by weight, add 10 parts of low-density hollow glass microspheres and 2 parts of nano-silicon dioxide to the mixed material 1, and stir at a speed of 200r / min for 20-40min to obtain the mixed material 2; the low-density hollow glass used Bulk density of microbeads≤1g / cm 3 ;

[0068] P3, in parts by weight, add 0.5 part of animal protein foaming agent and 0.2 part of sodium lauryl sulfate to the mixed material 2, stir and mix evenly to obtain the mixed material 3;

[0069] P4. In parts by weight, add 1 part of hydroxymethyl cellulose to t...

Embodiment 7

[0072] A preparation method for thermal insulation coating, which comprises the steps of:

[0073] P1. In parts by weight, 26 parts of styrene-ethyl acrylate copolymer emulsion, 13.5 parts of silicone-modified n-butyl acrylate emulsion, 9 parts of silicone emulsion with a concentration of 2% (w / w) and 0.3 parts of graphite Add alkene into the stirring tank, stir and mix at a speed of 600r / min to obtain a mixed material 1;

[0074] P2. In parts by weight, add 13 parts of low-density hollow glass microspheres and 3 parts of nano-silicon dioxide to the mixed material 1, and stir at a speed of 150r / min for 20-40min to obtain the mixed material 2; the low-density hollow glass used Bulk density of microbeads≤1g / cm 3 ;

[0075] P3, in parts by weight, add 0.6 part of animal protein foaming agent and 0.3 part of sodium lauryl sulfate to the mixed material 2, stir and mix evenly to obtain the mixed material 3;

[0076] P4. In parts by weight, add 2 parts of hydroxyethyl cellulose to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com