Oil-soluble graphene compound and preparation method and application thereof

A compound, graphene technology, used in lubricating compositions, petroleum industry, additives, etc., can solve problems such as agglomeration, affecting dispersion stability, and achieve excellent extreme pressure performance, good anti-wear performance, and excellent oil solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The present embodiment provides an oil-soluble graphene compound, specifically: graphene n-octadecylamide and octadecylmethoxy or ethoxysilane, that is, Γ (CONHC m H 2m+1 ) x [Si(OCH 3 ) z C p H 2p+1 ] y ; where m=18, z=1 or 2, p=18, 1≤x≤100, 1≤y≤100.

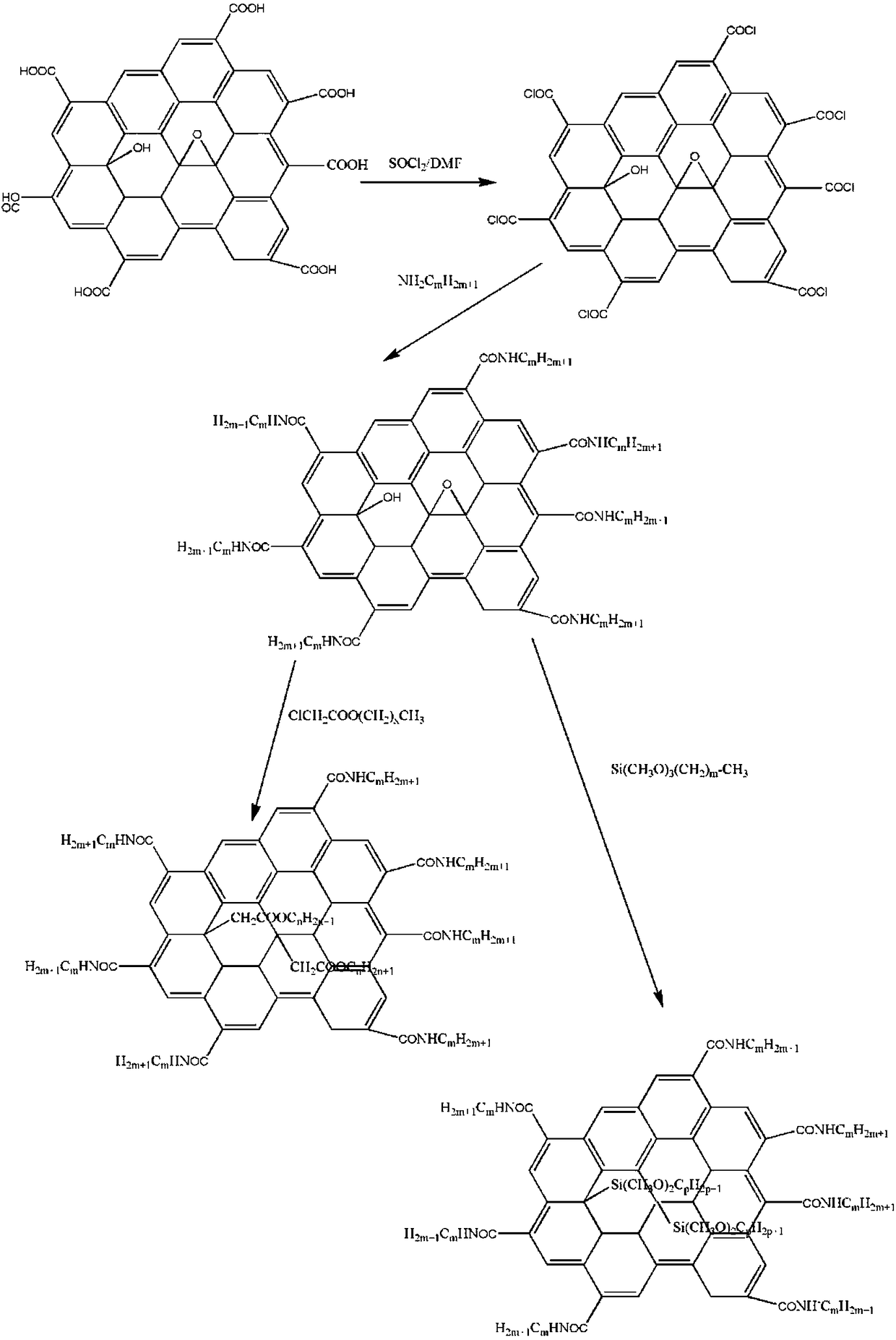

[0045] The present embodiment further provides a preparation method of the oil-soluble graphene compound, specifically:

[0046] (1) Add 0.75 ml of DMF and 100 mg of graphene oxide to a 50 ml three-necked bottle, seal it well, ultrasonicate for half an hour, and add 3 ml of thionyl chloride dropwise at a temperature below 10° C. After dripping nitrogen protection, the temperature is raised to 70° C. The reaction was carried out for 24 hours, transferred to a single-necked flask to remove the thionyl chloride by rotary evaporation, and then 10 ml*3 times of toluene was used to dry the residual thionyl chloride to obtain 0.32 g of a black solid.

[0047] (2) Under nitrogen protection, add 0.32g of the first step pr...

Embodiment 2

[0050] The present embodiment provides a kind of oil-soluble graphene compound, specifically: graphene n-octadecyl amide and methyl acetate, i.e. Γ (CONHC m H 2m+1 ) x (CH 2 COOC n H 2n+1 ) y ; where, m=18, n=1, 1≤x≤100, 1≤y≤100.

[0051] The present embodiment further provides a preparation method of the oil-soluble graphene compound, specifically:

[0052] (1) Add 0.75 ml of DMF and 100 mg of graphene oxide to a 50 ml three-necked bottle, seal it well, ultrasonicate for half an hour, and add 3 ml of thionyl chloride dropwise at a temperature below 10° C. After dripping nitrogen protection, the temperature is raised to 70° C. The reaction was carried out for 24 hours, transferred to a single-necked flask to remove the thionyl chloride by rotary evaporation, and then 10 ml*3 times of toluene was used to dry the residual thionyl chloride to obtain 0.32 g of a black solid.

[0053] (2) Under nitrogen protection, add 0.32g of the first step product and 3g of octadecylamine...

Embodiment 3

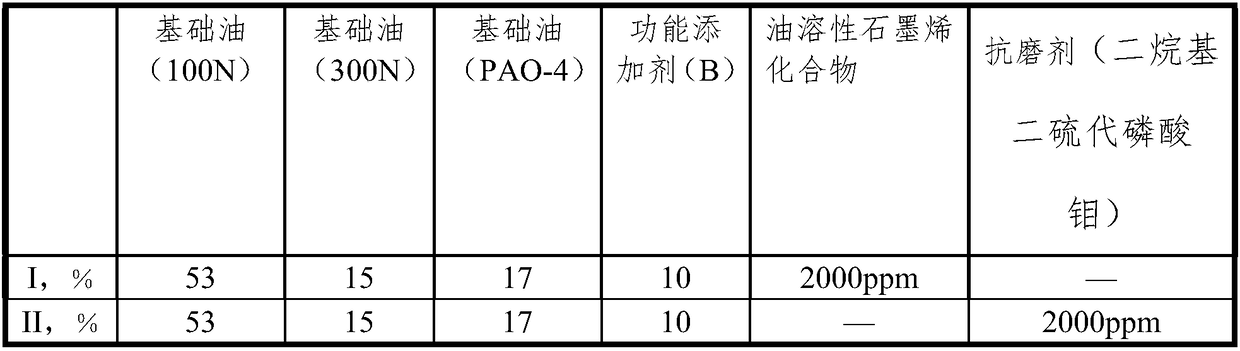

[0056] In this example, the oil-soluble graphene compound provided in Example 1 is used as an antiwear agent for gasoline engine oil. Specifically, according to the formula in Table 1, the oil-soluble graphene compound and the common organic molybdenum salt antiwear agent (such as molybdenum dialkyldithiophosphate) in the current market are respectively used as antiwear agents, and SN / GF-5 0W-20 gasoline engine oil.

[0057] Table 1 SN / GF-5 0W-20 gasoline engine oil

[0058]

[0059] Note: B* contains anti-wear additives.

[0060] The analysis results of the two groups of SN / GF-5 0W-20 gasoline engine oils obtained are shown in Table 2.

[0061] Table 2: Analysis results of SN / GF-5 0W-20 gasoline engine oil

[0062]

[0063] Note: M* friction pair mode: ball and disc, test conditions: 50hz, 200g, 80℃.

[0064] As can be seen from the analysis data in Table 2, with Γ (CONHC m H 2m+1 ) x [Si(OCH 3 ) z C p H 2p+1 ] y (m=18, z=1 or 2, p=18), the friction coeffic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com