Non-stick coating and preparation method thereof as well as cooking utensils and cooking device

A technology of non-stick coatings and pots, which is applied in coatings, metal material coating processes, kitchen utensils, etc., and can solve problems such as coating life and application limitations, coating peeling, failure, and low coating adhesion , to achieve the effect of small porosity, improved hydrophobicity and non-stickiness, and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

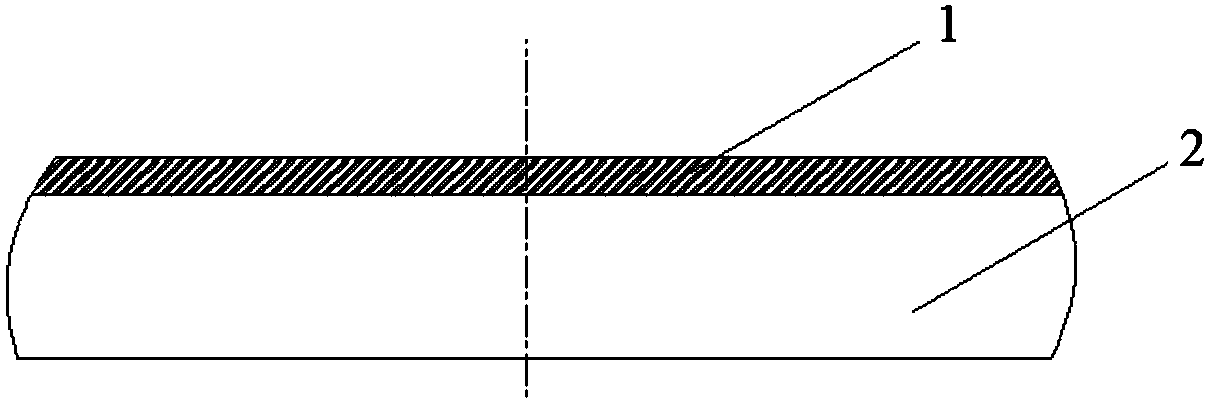

Image

Examples

preparation example Construction

[0074] Modified PFA powder A1, the preparation method includes: (1) 47.6kg common PFA powder, 0.4kg polyvinyl alcohol (purchased from Shanghai Fusichun Chemical Technology Co., Ltd., the model is PVA1788), 2kg glycerin and 50kg water are mixed to prepare slurry (2) The slurry is subjected to airflow atomization drying treatment, wherein the conditions of airflow atomization drying include: the atomization pressure is 0.4MPa, and the atomization air flow rate is 2m 3 / h, the inlet temperature is 320°C, and the air outlet temperature is 100°C to obtain modified PFA powder A1. The particle size D50 of the modified PFA powder A1 is 52 μm, the fluidity is 15 s / 50 g, the purity is 99.9%, the melting point is 410° C., and the surface roughness is Ra0.2 μm.

[0075] Modified PFA powder A2, the preparation method comprises: (1) 54.8kg common PFA powder, 0.2kg polyvinyl chloride (purchased from Shanghai Ji Ning Industrial Co., Ltd., model is K55-59), 3kg paraffin and 42kg water are mixe...

Embodiment 1

[0077] This example is used to illustrate the method of preparing non-stick coating by plasma spraying method.

[0078] (1) Pretreat the aluminum pan base (thickness 2.5mm), wherein the pretreatment method includes: a) degreasing at 55°C for 8 minutes; b) cleaning with deionized water; c) drying at 100°C 5min; d) Use 60-80 mesh brown steel grit to sandblast the inner surface of the aluminum pot base under the air jet pressure of 0.6MPa to make the surface roughness Ra3μm, and then use the air flow (air) to seal the inner surface of the pot base Blow off the powder particles remaining on the surface; e) wash with 40% by weight of NaOH solution at 80°C for 1 minute; f) neutralize with 20% by weight of nitric acid solution for 3 minutes; g) after cleaning with deionized water, 300 Dry at ℃ for 12 minutes;

[0079] (2) Preheating the substrate surface obtained in step (1) to 120°C;

[0080] (3) With alumina powder and modified PFA powder A1 as raw materials, a non-stick coating ...

Embodiment 2

[0083] This example is used to illustrate the method of preparing non-stick coating by plasma spraying method.

[0084] (1) with reference to the method in embodiment 1, aluminum pan substrate (thickness is 2.5mm) is carried out pretreatment;

[0085] (2) Preheating the substrate surface obtained in step (1) to 100°C;

[0086] (3) With titanium oxide powder and modified PFA powder A2 as raw materials, a non-stick coating is formed on the substrate surface through plasma spraying treatment; wherein, the conditions of plasma spraying treatment include: the spraying power of the plasma spray gun is 35kW, and the spraying current is 580A, the flow rate of argon gas in the working gas is 40L / min, and the flow rate of hydrogen gas is 3L / min; the spraying distance between the plasma spray gun and the substrate is 110mm, the spraying angle is 80°±1°, and the moving speed of the spray gun is 85mm / s; In the formed flame flow, titanium oxide powder is fed into the distance from the spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com