Treatment method for corrosion resistance of metal surfaces

A metal surface and treatment method technology, which is applied in the field of metal surface corrosion resistance treatment, can solve the problems of serious environmental pollution of electrolyte solution, bridge collapse, crash, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

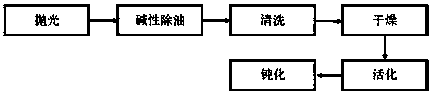

Method used

Image

Examples

Embodiment 1

[0025] A method for treating corrosion resistance of a metal surface, comprising the following steps in sequence:

[0026] 1) Polishing: Put the aluminum alloy to be polished in the main tank with a temperature of 95°C and a volume ratio of sulfuric acid to phosphoric acid of 7:2 for polishing. Cool in an auxiliary tank with a volume ratio of sulfuric acid and phosphoric acid of 7:2, and the cooling time is 1 hour. After cooling, place the metal in a recovery tank filled with clean water to recover and treat the residual liquid on the metal surface;

[0027] 2) Alkaline degreasing: Put the polished metal in an ultrasonic device with a mass concentration of 10g / L trisodium phosphate solution, and improve the degreasing effect of the trisodium phosphate solution on the metal by vibration. The temperature is 70°C, and the degreasing time is 6 minutes;

[0028] 3) Cleaning: Use a high-pressure cleaner to clean the metal after alkaline degreasing. The high-pressure cleaner sprays ...

Embodiment 2

[0034] A method for treating corrosion resistance of a metal surface, comprising the following steps in sequence:

[0035] 1) Polishing: Put the aluminum alloy to be polished in the main tank with a temperature of 95°C and a volume ratio of sulfuric acid to phosphoric acid of 7:2 for polishing. Cool in an auxiliary tank with a volume ratio of sulfuric acid and phosphoric acid of 7:2, and the cooling time is 1 hour. After cooling, place the metal in a recovery tank filled with clean water to recover and treat the residual liquid on the metal surface;

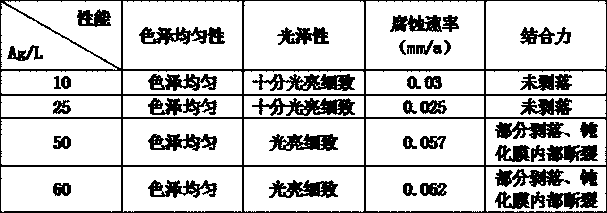

[0036] 2) Alkaline degreasing: Put the polished metal in an ultrasonic device with a mass concentration of Ag / L trisodium phosphate solution, and improve the degreasing effect of the trisodium phosphate solution on the metal by vibration. The temperature is 70°C, and the degreasing time is 6 minutes;

[0037] 3) Cleaning: Use a high-pressure cleaner to clean the metal after alkaline degreasing. The high-pressure cleaner sprays d...

Embodiment 3

[0047] A method for treating corrosion resistance of a metal surface, comprising the following steps in sequence:

[0048] 1) Polishing: Put the aluminum alloy to be polished in the main tank with a temperature of 95°C and a volume ratio of sulfuric acid to phosphoric acid of 7:2 for polishing. Cool in an auxiliary tank with a volume ratio of sulfuric acid and phosphoric acid of 7:2, and the cooling time is 1 hour. After cooling, place the metal in a recovery tank filled with clean water to recover and treat the residual liquid on the metal surface;

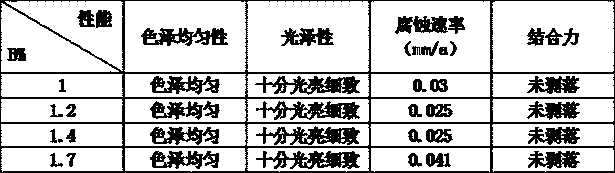

[0049] 2) Alkaline degreasing: Put the polished metal in an ultrasonic device with a mass concentration of 10g / L trisodium phosphate solution, and improve the degreasing effect of the trisodium phosphate solution on the metal by vibration. The temperature is 70°C, and the degreasing time is 6 minutes;

[0050] 3) Cleaning: Use a high-pressure cleaner to clean the metal after alkaline degreasing. The high-pressure cleaner sprays ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com