A three-dimensional nanoskeleton composite gel electrolyte material, preparation method and application thereof

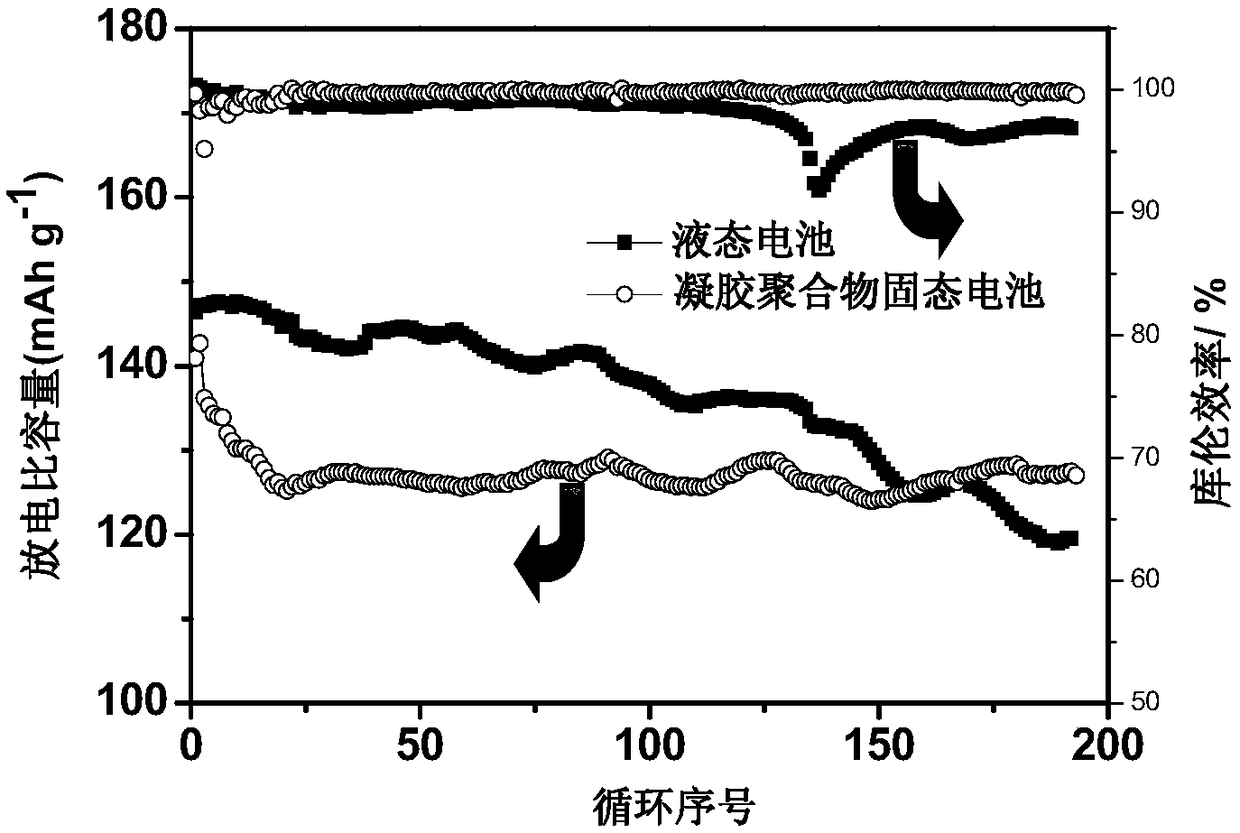

A technology of electrolyte material and composite gel, which is applied in the field of three-dimensional nano-skeleton composite gel electrolyte material and its preparation, can solve problems such as uneven distribution and agglomeration, achieve good repeatability, low cost, and improve Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a three-dimensional nano-skeleton composite gel electrolyte material, comprising the following steps:

[0035] (1) Refer to "A Novel Sol–Gel Method for Large-Scale Production of Nanopowders: Preparation of Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 as an Example, J.Am.Ceram.Soc., 2016, 99, 410-414." The method in the literature utilizes the sol-gel method to prepare Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 (LATP) hydrogel precursor, the hydrogel is scraped onto a ceramic plate with a thickness of no more than 100 μm, dried at 80°C for 24 hours to obtain a xerogel, and then calcined at 600°C for 3 hours to obtain a nano-LATP thin layer, Its thickness is 50 μm;

[0036] (2) PVDF-HFP, EC, DMC, DEC and LiPF 6Dissolved in N,N-dimethylformamide (DMF), under magnetic stirring to obtain a homogeneous viscous mixed solution, wherein the mass ratio of EC, DMC, and DEC is 1:1:1; PVDF-HFP, The mass ratio of EC+DMC+DEC and DMF is 2:1:5; the concentration of lithium salt...

Embodiment 2

[0042] A preparation method of a three-dimensional nano-skeleton composite gel electrolyte material, comprising the following steps:

[0043] (1) Preparation of Li by sol-gel method 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 (LATP) hydrogel precursor, the hydrogel is scraped on a ceramic plate with a thickness of no more than 100 μm, dried at 80°C for 24 hours to obtain a xerogel, and then calcined at 600°C for 3 hours to obtain a 50 μm nano-LATP thin layer ;

[0044] (2) PVDF-HFP, EC, DMC, DEC and LiPF 6 Dissolved in N,N-dimethylformamide (DMF), under magnetic stirring to obtain a homogeneous viscous mixed solution, wherein the mass ratio of EC, DMC, and DEC is 1:1:1; PVDF-HFP, The mass ratio of EC+DMC+DEC and DMF is 1:2:5; the concentration of lithium salt relative to EC+DMC+DEC is 1mol / L;

[0045] (3) Drop the mixed solution into the nano-LATP thin layer, and scrape it into a wet film with uniform thickness with a scraper;

[0046] (4) The obtained wet film was vacuum-dried at roo...

Embodiment 3

[0050] A preparation method of a three-dimensional nano-skeleton composite gel electrolyte material, comprising the following steps:

[0051] (1) Preparation of Li by sol-gel method 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 (LATP) hydrogel precursor, the hydrogel is scraped on a ceramic plate with a thickness of no more than 100 μm, dried at 80°C for 24 hours to obtain a xerogel, and then calcined at 600°C for 3 hours to obtain a 50 μm nano-LATP thin layer ;

[0052] (2) PVDF-HFP, EC, DMC, DEC and LiPF 6 Dissolved in N,N-dimethylformamide (DMF), under magnetic stirring to obtain a homogeneous viscous mixed solution, wherein the mass ratio of EC, DMC, and DEC is 1:1:1; PVDF-HFP, The mass ratio of EC+DMC+DEC and DMF is 1:1:5; the concentration of lithium salt relative to EC+DMC+DEC is 1mol / L;

[0053] (3) Drop the mixed solution into the nano-LATP thin layer, and scrape it into a wet film with uniform thickness with a scraper;

[0054] (4) The obtained wet film was vacuum-dried at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com