Attapulgite-chitosan composite gel and preparation method thereof

A composite gel and composite hydrogel technology, applied in the field of clay deep processing, can solve the problems of application limitation, poor mechanical properties of chitosan physical gel, etc., and achieve the effects of reduced preparation cost, safe and environmentally friendly process, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

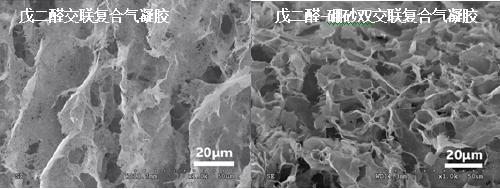

[0022] This embodiment improves a chitosan-attapulgite composite gel, which is composed of components in the following mass ratio: attapulgite: chitosan: glutaraldehyde: borax=100:12:1.44:3.

[0023] Crush the attapulgite to 200 mesh, acidify it with 2wt% acetic acid for 6 hours, discard the non-clay impurities in the lower layer by centrifugal sedimentation, then reconfigure the slurry into a 2wt% attapulgite slurry, and adjust the pH of the attapulgite slurry to about 4 , and then add an appropriate amount of 4wt% chitosan solution (wherein the mass ratio of the attapulgite in the attapulgite slurry to the chitosan in the chitosan solution is 1:0.12), and stir evenly, continue to add an appropriate amount of 5wt% Glutaraldehyde solution stirred 30min (wherein, the glutaraldehyde consumption in glutaraldehyde solution is 12% of chitosan quality in chitosan solution), continues to add 0.4mol / L borax solution and stirs (wherein, borax consumption is ⩽ 3% of the mass of the atta...

Embodiment approach 2

[0026] This embodiment improves a chitosan-attapulgite composite gel, which is composed of components in the following mass ratio: attapulgite: chitosan: glutaraldehyde: borax=100:25:2.5:4.

[0027] The attapulgite was crushed to 200 mesh, acidified with 2wt% acetic acid for 6h, and the non-clay impurities in the lower layer were discarded by centrifugal sedimentation, and then the slurry was reconfigured into a 3.5wt% attapulgite slurry, and the pH of the attapulgite slurry was adjusted to 4 Then add an appropriate amount of 4wt% chitosan solution (wherein the mass ratio of the attapulgite in the attapulgite slurry to the chitosan in the chitosan solution is 1:0.25) and stir evenly, continue to add an appropriate amount of 5wt% Glutaraldehyde solution stirred 30min (wherein, the glutaraldehyde consumption in glutaraldehyde solution is 10% of chitosan quality in chitosan solution), continues to add 0.4mol / L borax solution and stirs (wherein, borax consumption is ⩽ 4% of the at...

Embodiment approach 3

[0030] This embodiment improves a chitosan-attapulgite composite gel, which is composed of components in the following mass ratio: attapulgite: chitosan: glutaraldehyde: borax=100:30:4.5:5.

[0031] Crush the attapulgite to 200 mesh, acidify it with 2wt% acetic acid for 6 hours, discard the non-clay impurities in the lower layer by centrifugal sedimentation, then reconfigure the slurry into a 4wt% attapulgite slurry, and adjust the pH of the attapulgite slurry to about 4 , and then add an appropriate amount of 4wt% chitosan solution (the mass ratio of the attapulgite in the attapulgite slurry to the chitosan in the chitosan solution is 1:0.3), stir evenly, and continue to add an appropriate amount of 5wt% Glutaraldehyde solution stirred 30min (wherein, the glutaraldehyde consumption in glutaraldehyde solution is 15% of chitosan quality in chitosan solution), continues to add 0.4mol / L borax solution and stirs (wherein, borax consumption is ⩽ 5% of the mass of the attapulgite in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com