Aqueous phase preparation method of maleic anhydride-conjugated diene copolymer

A technology of maleic anhydride and conjugated diene, which is applied in the field of aqueous phase preparation of maleic anhydride-conjugated diene copolymer, can solve the problems of high pollution and toxicity, impact on the environment and human health, and achieve improved reaction Efficiency, the effect of improving the induction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

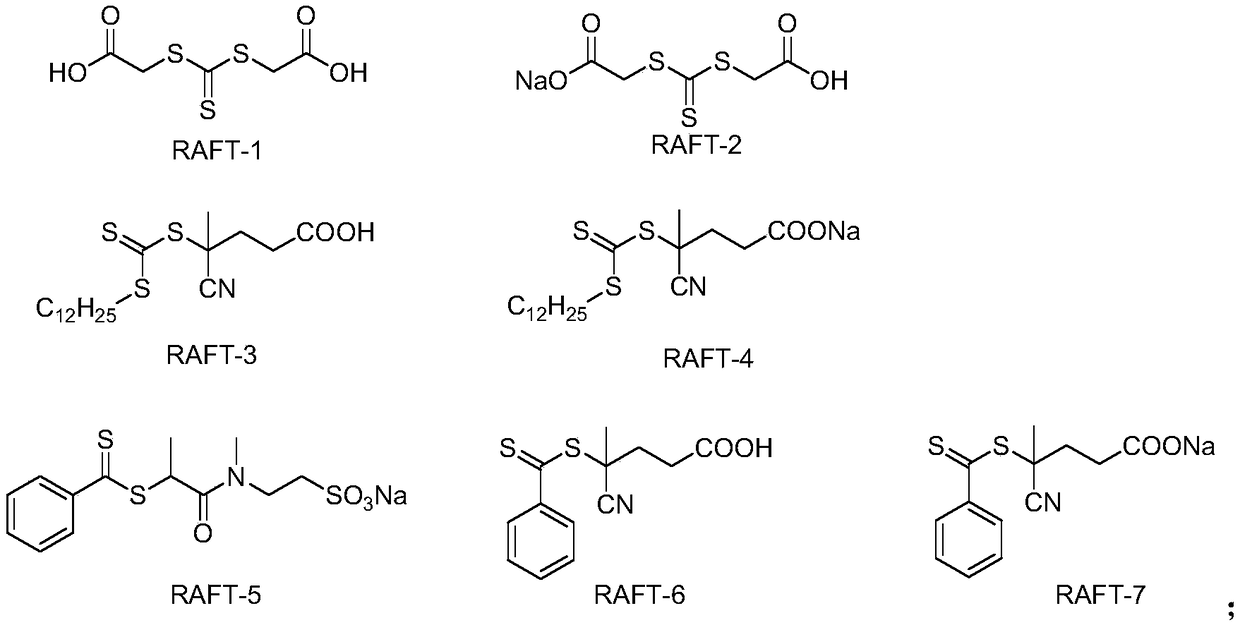

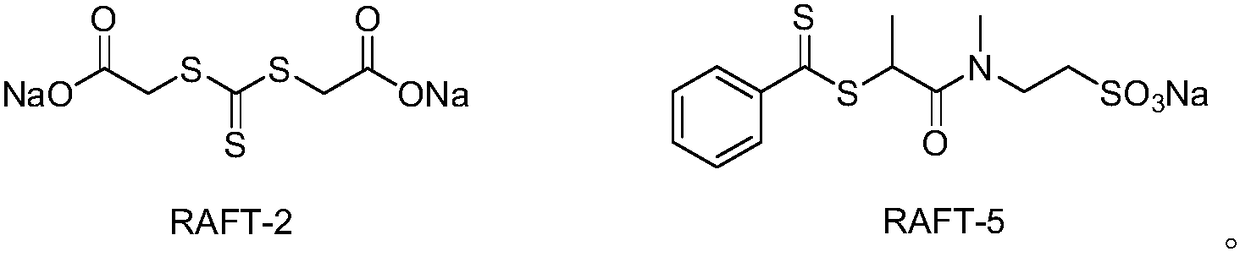

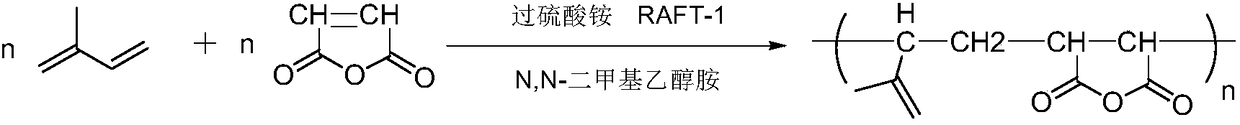

Method used

Image

Examples

Embodiment 1

[0036]

[0037] Add 9.806g maleic anhydride, 0.304g RAFT-1, 0.108g N,N-dimethylethanolamine and 40.000g distilled water into the reactor and stir to dissolve; heat up to 60°C, slowly add 5.409g isoprene and 0.304 g ammonium persulfate initiator, stirred at a constant speed; after the dropwise addition, the temperature was raised to 95-100°C to continue the reaction for 2 hours; the temperature was lowered to room temperature, and the pH was adjusted to neutral with alkali to obtain an aqueous solution of maleic anhydride-isoprene copolymer. The viscosity average molecular weight is 19700, and the molecular weight distribution is 2.0.

Embodiment 2

[0039]

[0040] Add 9.806g maleic anhydride, 0.304g RAFT-5, 0.108g N,N-dimethylethanolamine and 40.000g distilled water into the reactor and stir to dissolve; heat up to 65°C, slowly add 5.409g isoprene and 0.304 g ammonium persulfate initiator, stirred at a constant speed; after the dropwise addition, the temperature was raised to 95-100°C to continue the reaction for 2 hours; the temperature was lowered to room temperature, and the pH was adjusted to neutral with alkali to obtain an aqueous solution of maleic anhydride-isoprene copolymer. The viscosity average molecular weight is 18000, and the molecular weight distribution is 1.8.

Embodiment 3

[0042]

[0043] Add 9.806g maleic anhydride, 0.304g RAFT-1, 0.108g pentaerythritol triacrylate and 40.000g distilled water into the reactor and stir to dissolve; heat up to 70°C, slowly add 5.409g isoprene and 0.304g ammonium persulfate Initiator, stir at a constant speed; after the dropwise addition, raise the temperature to 95-100°C to continue the reaction for 2 hours; cool down to room temperature, adjust the pH to neutral with alkali, and obtain an aqueous solution of maleic anhydride-isoprene copolymer with a viscosity-average molecular weight of 18,500 , molecular weight distribution 1.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com