Anticorrosive paint and preparation method thereof

A technology for anti-corrosion coatings and primer materials, applied in the direction of anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of complex preparation process, no coating given, and difficulty in obtaining coatings, etc., to achieve simple formula, anti-corrosion Performance improvement, simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

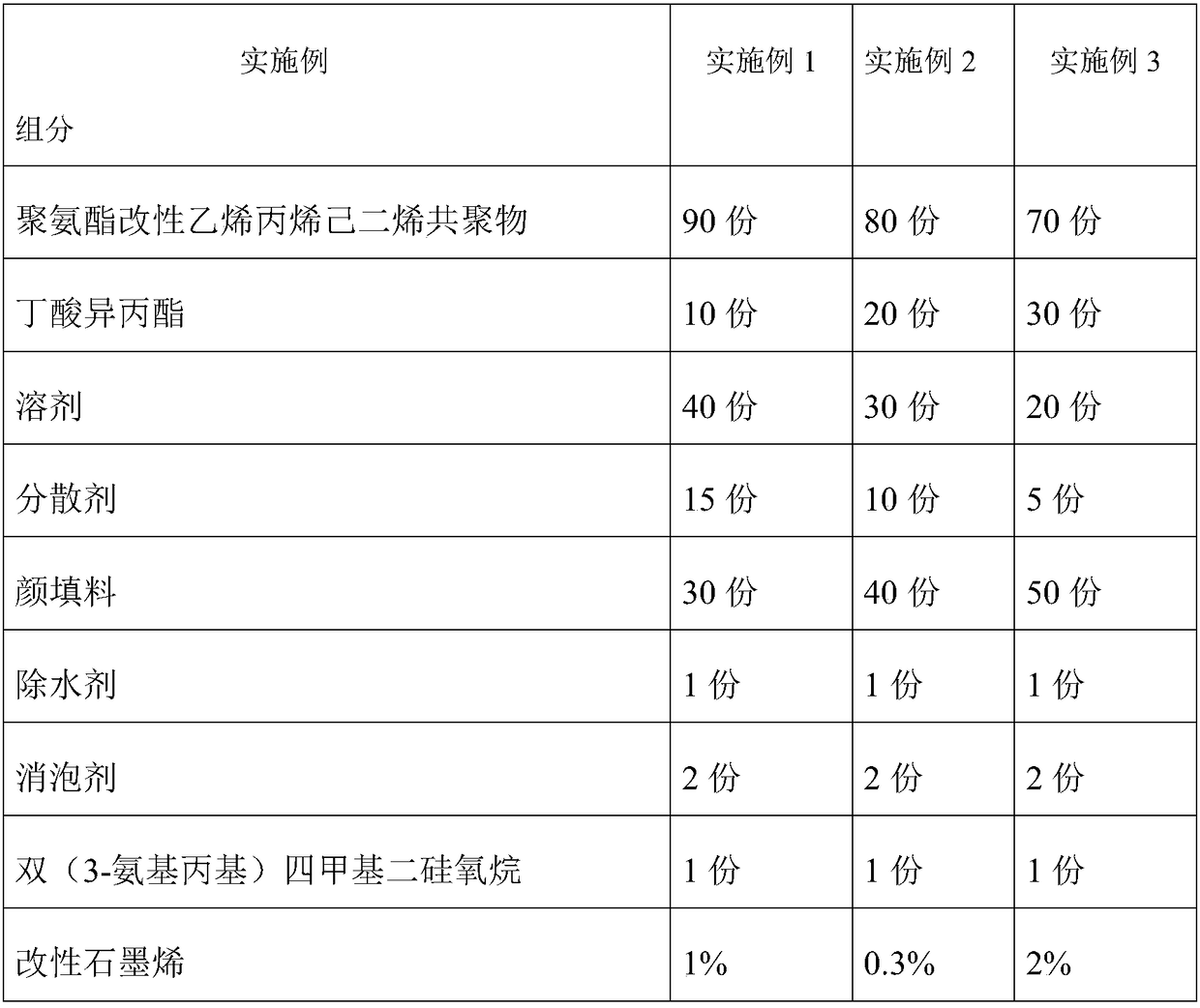

[0045] This example provides an anti-corrosion coating and a preparation method thereof. The raw material formula of the anti-corrosion coating is shown in Table 1, wherein the solvent is methyl isobutyl ketone; the dispersant is polycarboxylate dispersant BYK163; the water remover is oxazolidine and calcium chloride in a weight ratio of 1:0.2 . Pigments and fillers are composed of titanium dioxide, barium metaborate, zinc aluminum alloy powder, and silicon dioxide in a ratio of 1:0.3:1.5:0.8.

[0046] The preparation method of anticorrosion coating is as follows:

[0047] (1), according to the formula ratio, the polyurethane modified ethylene propylene hexadiene copolymer and isopropyl butyrate are put into the first mixer for stirring and mixing, and the stirring time is 30 minutes;

[0048] (2), adding the mixture obtained in step (1) into the first reaction kettle, controlling the temperature at 300° C., and reacting for 3 hours to obtain a spherical network polymer resi...

Embodiment 2

[0054] This example provides an anti-corrosion coating and a preparation method thereof. The raw material formula of anti-corrosion coating is shown in Table 1, in which, the solvent is methyl isobutyl ketone; the dispersant is polycarboxylate dispersant BYK163; the dewatering agent is composed of oxazolidine and calcium chloride in a weight ratio of 1:5 . Pigments and fillers are composed of titanium dioxide, barium metaborate, zinc aluminum alloy powder, and silicon dioxide in a ratio of 1:0.1:0.8:1.

[0055] The preparation method of this example with wet band rust anticorrosion primer material is basically the same as embodiment 1.

Embodiment 3

[0057] This example provides an anti-corrosion coating and a preparation method thereof. The raw material formula of the anti-corrosion coating is shown in Table 1. Among them, the solvent is methyl butanone; the dispersant is polycarboxylate dispersant BYK9076; the water remover is oxazolidine in a weight ratio of 1:2. Pigments and fillers are composed of red iron oxide, barium metaborate, and silicon dioxide in a ratio of 1:0.1:1.

[0058] The preparation method of this example anticorrosion coating is as follows:

[0059] (1), according to the formula ratio, the polyurethane modified ethylene propylene hexadiene copolymer and isopropyl butyrate are put into the first mixer for stirring and mixing, and the stirring time is 30 minutes;

[0060] (2), adding the mixture obtained in step (1) into the first reaction kettle, controlling the temperature at 250° C., and reacting for 4 hours to obtain a spherical network polymer resin;

[0061] (3), put other raw materials in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com