Gamma-polyglutamic acid producing bacterium and method for efficiently synthesizing gamma-polyglutamic acid

A polyglutamic acid and bacteria-producing technology, applied in the field of microbial fermentation, can solve the problems of long production cycle and low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

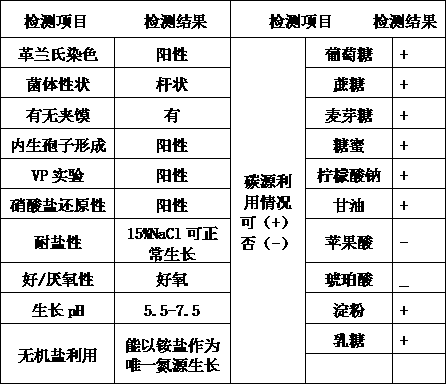

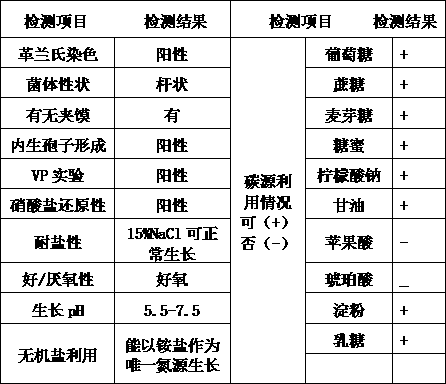

Image

Examples

Embodiment 1

[0077] Slant medium components: peptone 10g / L, yeast powder 5g / L, sodium chloride 10g / l, agar 15g / L, pH 7.0, sterilized at 121°C for 20 minutes.

[0078] Preparation of seed medium: peptone 10g / L, yeast powder 5g / L, sodium chloride 10g / L, pH7.0, sterilized at 121°C for 20 minutes.

[0079] Fermentation medium preparation: glucose 40g / L, peptone 5 g / L, sodium glutamate 30 g / L, K2HPO4 3H2O 2g / L, MgSO4 0.25 g / L, ammonium sulfate 3 g / L, manganese sulfate 0.1g / L L, pH7.0, sterilized at 115°C for 15 minutes (glucose is sterilized separately from other components).

[0080] The cryopreserved Bacillus subtilis (Bacillus Subtilis) W84 strain was inoculated on the slant medium for activation, and cultured at 37°C for 20h. Inoculate the strain activated on the slant into the seed medium, and culture at 37° C. for 12 h with a shaker rotating at 200 rpm.

[0081] Put the seed solution activated in the previous step into the fermentation medium of the shake flask, the inoculum amount is 2...

Embodiment 2

[0084] Slant-plane activation of strains: the same as in Example 1.

[0085] Seed medium preparation: glucose 20 g / L; sodium glutamate 5 g / L; dipotassium hydrogen phosphate 2 g / L; magnesium sulfate 2.5 g / L; yeast extract 5 g / L; manganese sulfate 0.2 g / L, pH 7.0. Sterilize at 115°C for 15 minutes (glucose is sterilized separately from other components).

[0086] Preparation of fermentation medium: glucose 40g / L, peptone 5 g / L, sodium glutamate 50 g / L, dipotassium hydrogen phosphate 8g / L, magnesium sulfate 0.5 g / L, ammonium sulfate 3 g / L, manganese sulfate 0.1g / L, pH7.0, sterilized at 115°C for 15 minutes (glucose is sterilized separately from other components).

[0087]The cryopreserved Bacillus subtilis (Bacillus Subtilis) W84 strain was inoculated on the slant medium for activation, and cultured at 37°C for 20h. Inoculate the strain activated on the slant into the seed medium, and culture at 37° C. for 12 h with a shaker rotating at 200 rpm.

[0088] Put the seed solution ...

Embodiment 3

[0091] Slant-plane activation of strains: the same as in Example 1.

[0092] Seed medium preparation: glucose 20 g / L; sodium glutamate 5 g / L; dipotassium hydrogen phosphate 2 g / L; magnesium sulfate 2.5 g / L; yeast extract 5 g / L; manganese sulfate 0.2 g / L, pH 7.0. Sterilize at 115°C for 15 minutes (glucose is sterilized separately from other components).

[0093] Preparation of fermentation medium: sucrose 40g / L, peptone 5 g / L, sodium glutamate 50 g / L, dipotassium hydrogen phosphate 8 g / L, magnesium sulfate 0.5 g / L, ammonium sulfate 3 g / L, sulfuric acid Manganese 0.1g / L, pH7.0, sterilized at 115°C for 15 minutes.

[0094] The cryopreserved Bacillus subtilis (Bacillus Subtilis) W84 strain was inoculated on the slant medium for activation, and cultured at 37°C for 20h. Inoculate the strain activated on the slant into the seed medium, and culture at 37° C. for 12 h with a shaker rotating at 200 rpm.

[0095] Put the seed solution activated in the previous step into the fermentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com