Method for preparing vanadium pentoxide from high-chrome vanadium slag

A vanadium pentoxide and high-chromium technology, applied in the field of vanadium chemical technology and resource recycling, can solve problems such as reducing production costs and pollution, and achieve the effects of avoiding water pollution, less ammonium salt consumption, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

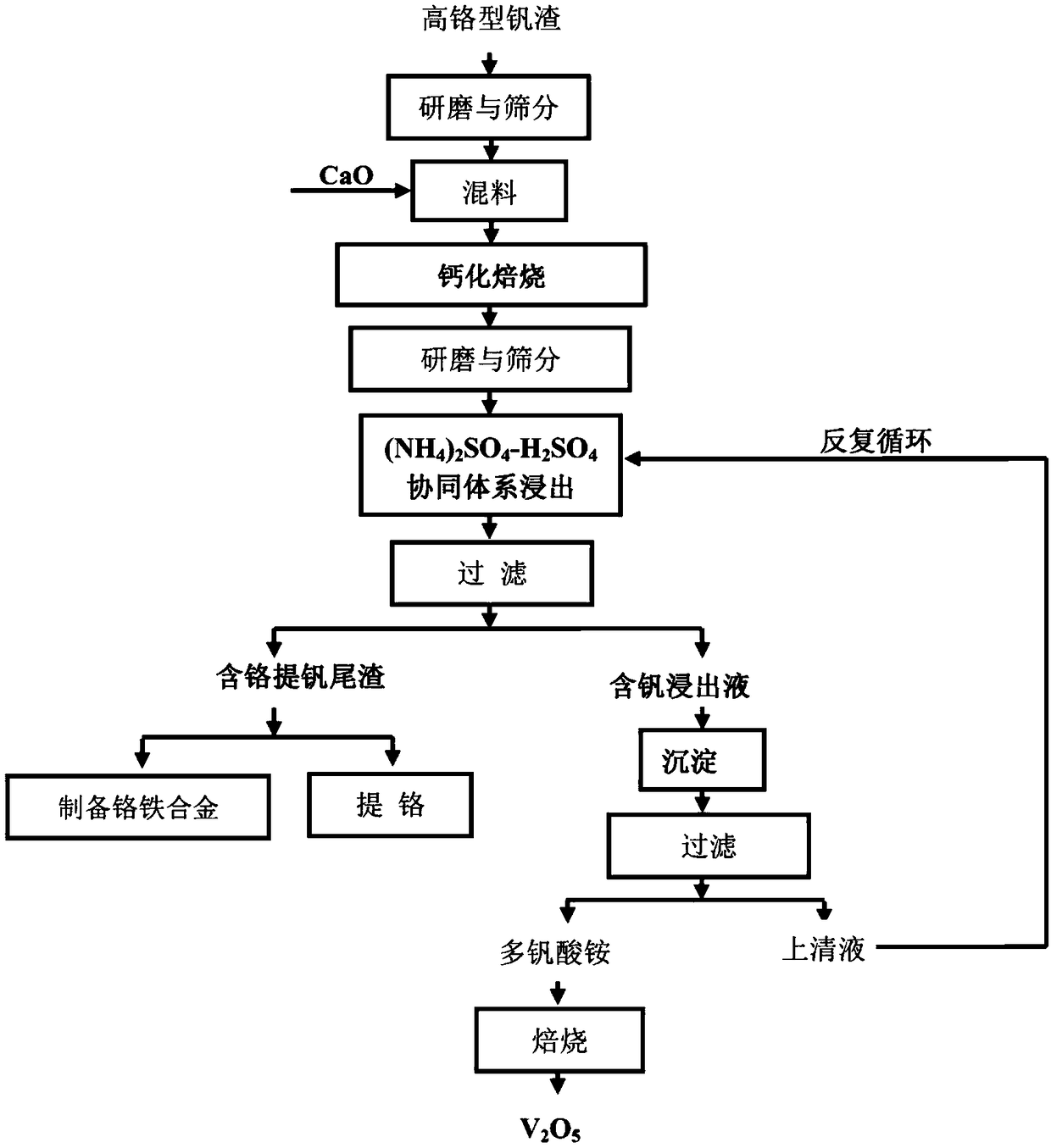

[0034] A method for preparing vanadium pentoxide by using high chromium type vanadium slag, the process flow is as follows figure 1 shown, including the following steps:

[0035] (1) Roasting: Grind and sieve the high-chromium vanadium slag, add calcium oxide for mixing, and then perform calcification and roasting. The particle size of the high-chromium vanadium slag is 150-300 mesh, so as to facilitate the oxidation of vanadium in the vanadium slag. Calcification. Among them, the vanadium content of the high chromium type vanadium slag used (in V 2 o 5 Calculated) is 14.42%, chromium content (as Cr 2 o 3 Calculated) is 9.45%, mixes evenly with calcium oxide, by molar ratio, calcium oxide: V in vanadium slag 2 o 5 =1; Roasting at 900°C for 60 minutes to obtain roasted clinker; the particle size of the roasted clinker after crushing is 250-300 mesh.

[0036] (2) Leaching: the roasted clinker obtained in step (1) is placed in (NH 4 ) 2 SO 4 -H 2 SO 4 Leach in the col...

Embodiment 2

[0042] A method for preparing vanadium pentoxide by utilizing high chromium type vanadium slag, comprising the steps of:

[0043] (1) Roasting: Grind and sieve the high-chromium vanadium slag, add calcium carbonate for mixing, and then calcify and roast. Calcification. Among them, the vanadium content of the high chromium type vanadium slag used (in V 2 o 5 Calculated) is 10.38%, chromium content (as Cr 2 o 3 Calculated) is 13.27%, mixes evenly with calcium carbonate, by molar ratio, calcium carbonate: V in the vanadium slag 2 o 5 =2. Roasted at 850°C for 180 minutes to obtain roasted clinker; the crushed particle size of the roasted clinker was 250-300 mesh.

[0044] (2) Leaching: (NH4) 2 SO 4 -H 2 SO 4 The synergistic leaching system consists of 50g / L (NH 4 ) 2 SO 4 solution and 20% volume fraction of H 2 SO 4 The solution constitutes, where (NH 4 ) 2 SO 4 solution with H 2 SO 4 The volume ratio of solution is 60; The roasted clinker that step (1) obtains...

Embodiment 3

[0050] A method for preparing vanadium pentoxide by utilizing high chromium type vanadium slag, comprising the steps of:

[0051] (1) Roasting: Grind and sieve the high-chromium vanadium slag, add calcium oxide for mixing, and then calcify and roast. The particle size of the high chromium vanadium slag is 150-300 mesh, so as to facilitate the oxidation and calcification of vanadium in the vanadium slag. Among them, the vanadium content of the high chromium type vanadium slag used (in V 2 o 5 Calculated) is 11.97%, chromium content (as Cr 2 o 3 Calculated) is 10.24%, mixes evenly with calcium oxide, by molar ratio, calcium oxide: V in the vanadium slag 2 o 5 = 3.5. Roasting at 850°C for 120 minutes to obtain roasted clinker; the crushed particle size of the roasted clinker is 250-300 mesh.

[0052] (2) Leaching: (NH 4 ) 2 SO 4 -H 2 SO 4 The synergistic leaching system consists of 250g / L (NH 4 )2 SO 4 solution and 20% volume fraction of H 2 SO 4 The solution cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com