Preparation method of sintered NdFeB magnet with low carbon content

A technology of NdFeB and carbon content, which is applied in the direction of magnetic objects, magnetic materials, metal processing equipment, etc., and can solve problems affecting the service life and corrosion resistance of magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

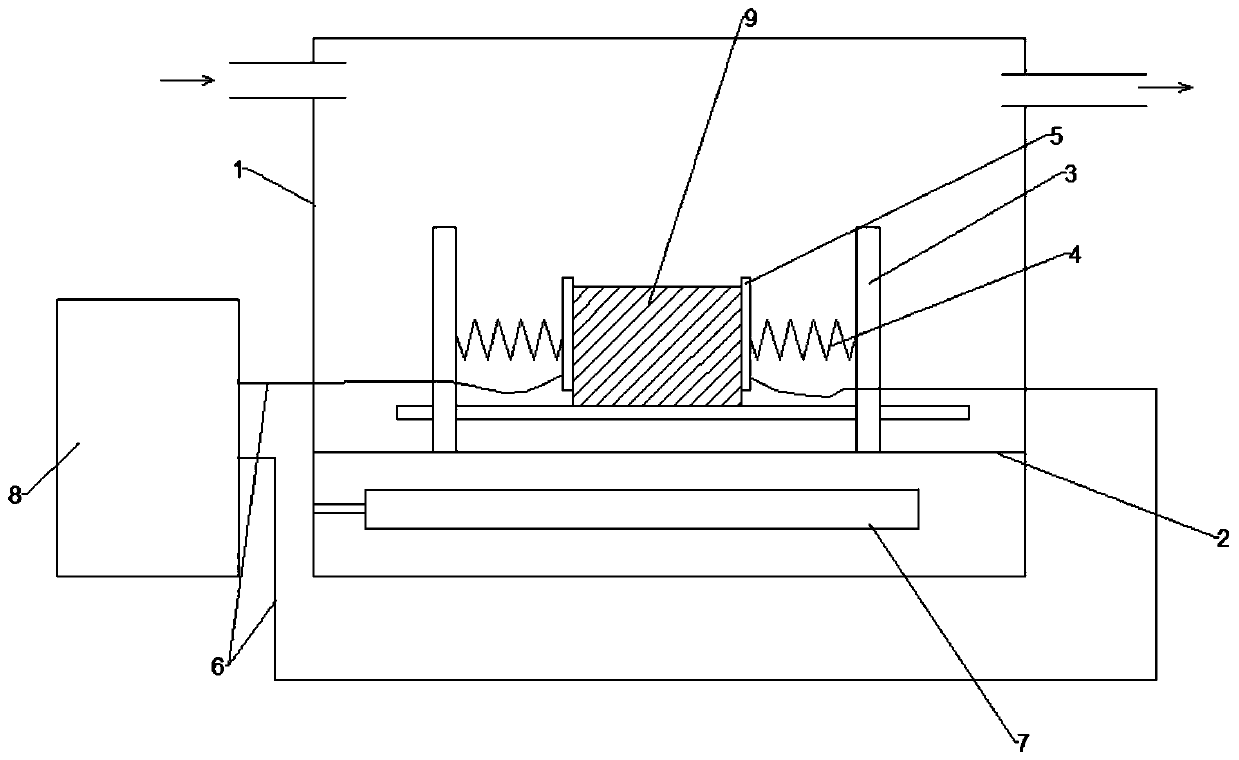

Image

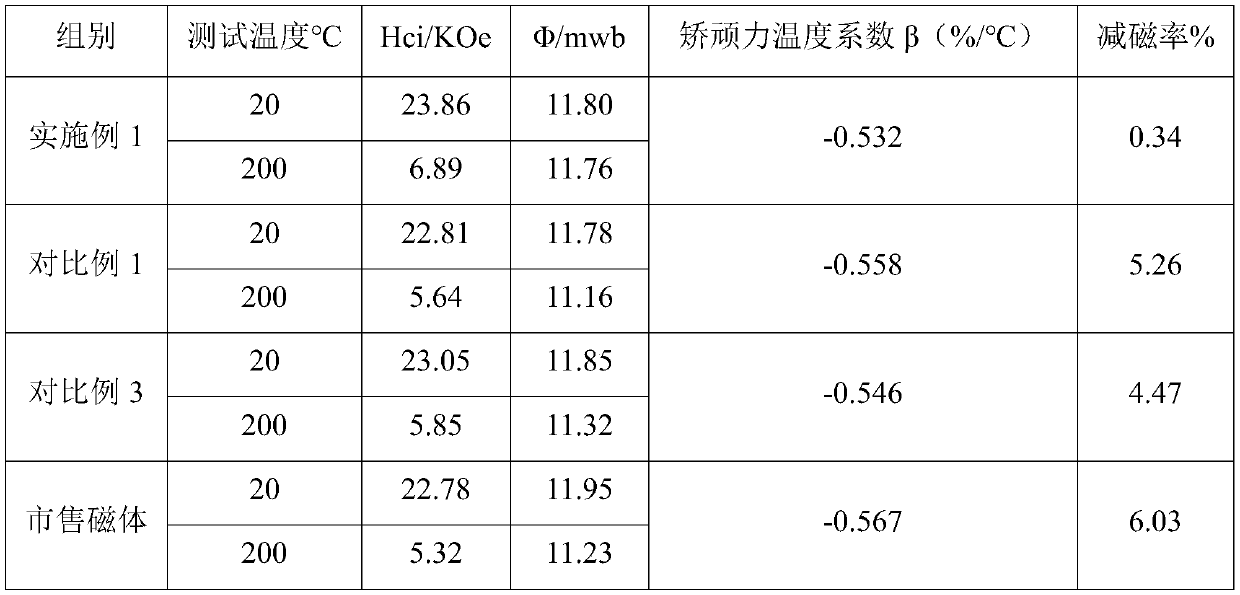

Examples

Embodiment 1

[0028] The preparation method of the sintered NdFeB magnet with low carbon content comprises the following steps:

[0029] Step 1. Carry out vacuum smelting of NdFeB magnet raw materials to obtain NdFeB magnet alloys, wherein, the NdFeB magnet raw materials include: Nd 35%, B 2.5%, Cu 1.8%, Si 1.8%, The balance is Fe;

[0030] Step 2: The NdFeB magnet alloy is subjected to hydrogen explosion treatment, and then 0.1% of the mass of the NdFeB magnet alloy is added with a protective agent. After mixing, the NdFeB magnet powder is made into NdFeB powder by jet milling with argon protection, and then pressed to obtain Neodymium-iron-boron green body 9, wherein the protective agent consists of 50% zinc stearate, 30% butyl acetate, and 20% turpentine by mass percentage;

[0031] Step 3: Apply 100V voltage to the opposite sides of the NdFeB green body 9, and energize it for 1 hour, and during the whole electrification process, the NdFeB green body 9 is filled with argon, and the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com