Preparation method of breathable and moisture transferring fabric

A technology of fabrics and amino acids, applied in the field of fabrics, can solve the problems of poor hygroscopicity, static electricity and difficulty of polyester, and achieve the effects of improving hygroscopicity, good washing resistance, and improving hygroscopicity and air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a breathable and moisture-conducting fabric, specifically comprising the following steps:

[0045] S1, protection reaction of amino group

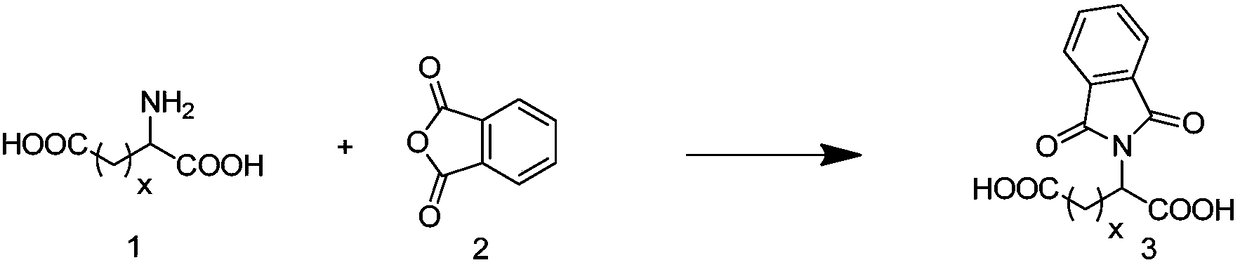

[0046] Add 200 mol of amino acid 1 and 400 mol of phthalic anhydride 2 into the reaction flask, add the solvent methylene chloride, heat to reflux for 1.5 hours, and remove the solvent by rotary evaporation after the reaction, to obtain the protected amino acid with the structure of formula 3, The yield is 96%; wherein, x in amino acid 1 is 1, and amino acid 1 is aspartic acid;

[0047]

[0048] S2, Esterification precondensation

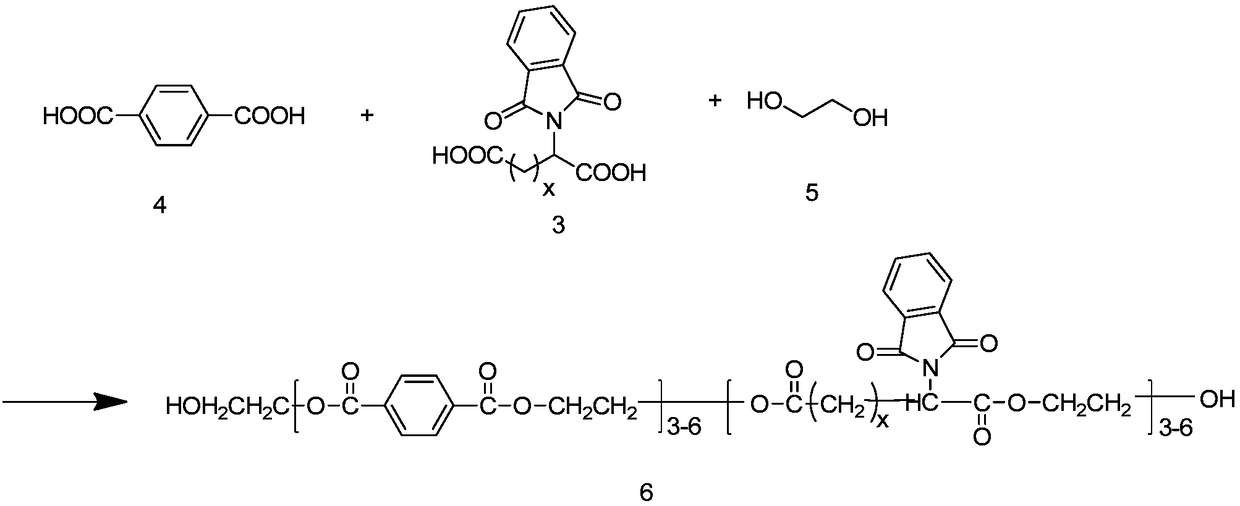

[0049] Add 100mol of terephthalic acid 4, 100mol of protected amino acid 3, 400mol of ethylene glycol 5 and 0.4mol of catalyst aluminum acetate into a stainless steel reaction kettle, pass through nitrogen protection, and heat up to 210°C under a pressure of 0.2MPa to carry out esterification. , the oligomer 7 was obtained;

[0050]

[0051] S3, polycondensation reaction

[...

Embodiment 2

[0062] A method for preparing a breathable and moisture-conducting fabric, specifically comprising the following steps:

[0063] S1, protection reaction of amino group

[0064] Add 200 mol of amino acid 1 and 300 mol of phthalic anhydride 2 into the reaction flask, add the solvent methylene chloride, heat to reflux for 2 hours, and remove the solvent by rotary evaporation after the reaction, to obtain the protected amino acid with the structure of formula 3. The rate is 98%; wherein, x in amino acid 1 is 2, and amino acid 1 is glutamic acid;

[0065]

[0066] S2, Esterification precondensation

[0067]

[0068] Add 70 mol of terephthalic acid 4, 30 mol of protected amino acid 3, 180 mol of ethylene glycol 5 and 0.3 mol of catalyst aluminum acetate into a stainless steel reaction kettle, pass through nitrogen protection, and heat up to 225°C under a pressure of 0.2 MPa to perform esterification. , the oligomer 7 was obtained;

[0069] S3, polycondensation reaction

[...

Embodiment 3

[0080] A method for preparing a breathable and moisture-conducting fabric, specifically comprising the following steps:

[0081] S1, protection reaction of amino group

[0082] Add 200 mol of amino acid 1 and 440 mol of phthalic anhydride 2 into the reaction flask, add the solvent dichloromethane, heat to reflux for 2 hours, and remove the solvent by rotary evaporation after the reaction to obtain the protected amino acid with the structure of formula 3. The rate is 97%; wherein, x in amino acid 1 is 1, and amino acid 1 is aspartic acid;

[0083]

[0084] S2, Esterification precondensation

[0085] Add 60 mol of terephthalic acid 4, 40 mol of protected amino acid 3, 200 mol of ethylene glycol 5 and 0.25 mol of catalyst aluminum acetate into a stainless steel reaction kettle, pass in nitrogen protection, and under a pressure of 0.2 MPa, heat up to 220°C for esterification , the oligomer 7 was obtained;

[0086]

[0087] S3, polycondensation reaction

[0088] After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com