Preparation method of patterned graphene flexible strain sensor

A strain sensor and graphene technology, applied in the field of sensors, can solve problems such as difficult control, reduced pattern resolution, cumbersome process, etc., and achieve the effect of avoiding easy damage and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing a patterned graphene flexible strain sensor, comprising the following steps:

[0034] (1) Prepare a predetermined microstructure relief pattern on the surface of the hard substrate material by photolithography to obtain a patterned mold;

[0035] (2) mixing the elastomer and the curing agent to obtain a mixed slurry;

[0036] (3) coating the anti-adhesive agent on the surface of the patterned mold to form an anti-adhesive layer, then pouring the mixed slurry on the surface of the anti-adhesive layer to cure, and peeling off the cured parts to obtain a microfluidic mold;

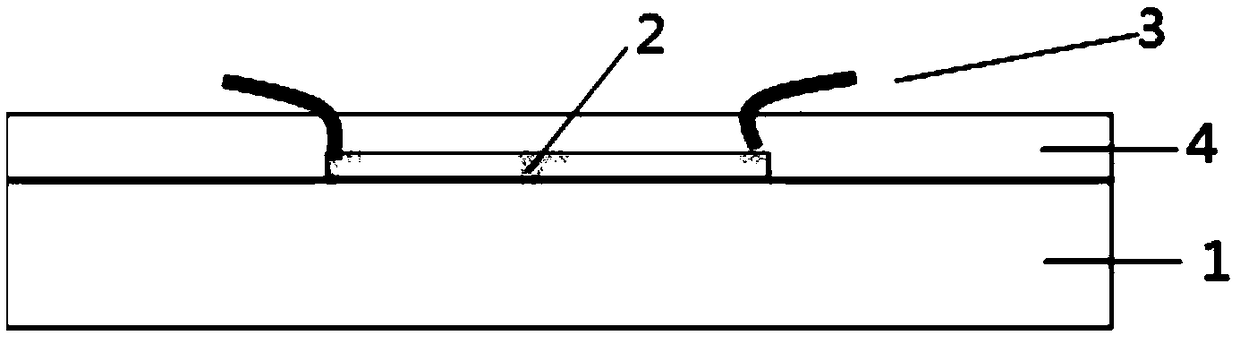

[0037] (4) A flexible substrate is provided, the microfluidic mold is covered on the surface of the flexible substrate to form a microfluidic member, the microfluidic member is immersed in a dopamine solution, and then the microfluidic mold is uncovered to obtain a pattern Chemically modified flexible substrates;

[0038] (5) Coating the graphene-graphene...

Embodiment 1

[0068] (1) Fabrication of patterned molds: Microstructure relief patterns are produced on silicon substrates by photolithography, and a layer of anti-sticking agent is coated on the surface of the pattern. The anti-sticking agent is selected from 1H, 1H, 2H, 2H-perfluorooctane Heating 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane at 100°C to make it volatilize steam, fumigate the pattern side of the silicon substrate, and the fumigation time is 6h , that is, successful conformal coating on the mold surface to form an adhesive layer.

[0069] (2) Preparation of microfluidic mold: mix PDMS basic components with curing agent (mixing mass ratio is 10:1), stir well with a stirrer, and then ultrasonically in an ultrasonic cleaner for 5-10 minutes until the bubbles completely disappear, Then pour it on the surface of the anti-adhesive layer of the patterned mold, place it in an oven at 60°C for 1 hour to cure, and the cured PDMS can be easily peeled off from the surface of the pattern...

Embodiment 2

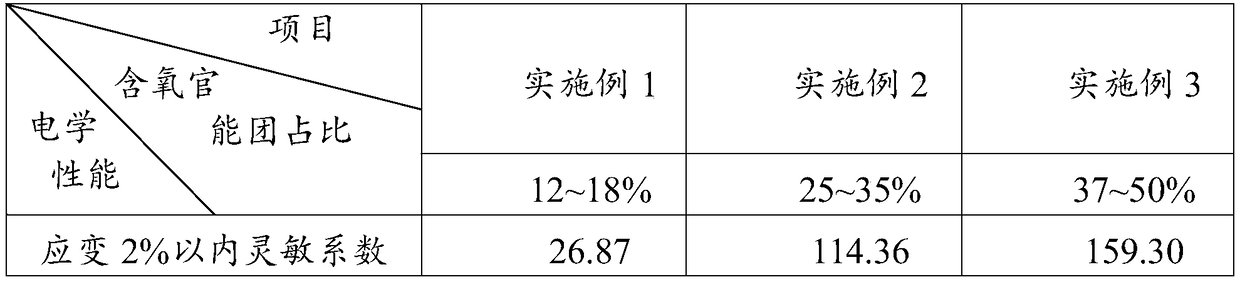

[0077] Other steps are identical with embodiment 1, only change the volume of the N-methylpyrrolidone dispersion liquid of graphene into 0.06mL in step (4), change the volume of the N-methylpyrrolidone dispersion liquid of graphene oxide into 0.04mL. Using XPS spectrum to test, the content of oxygen-containing functional groups in the mixed solution can be found to be 25-35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com