A nano silicon-carbon composite material and a preparation method and application thereof

A technology of carbon composite materials and nano-silicon, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult formation of stable SEI film, impact on battery performance, additive consumption, etc., to achieve Effects of improving electrochemical performance, improving electrical conductivity, improving conductivity and buffering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

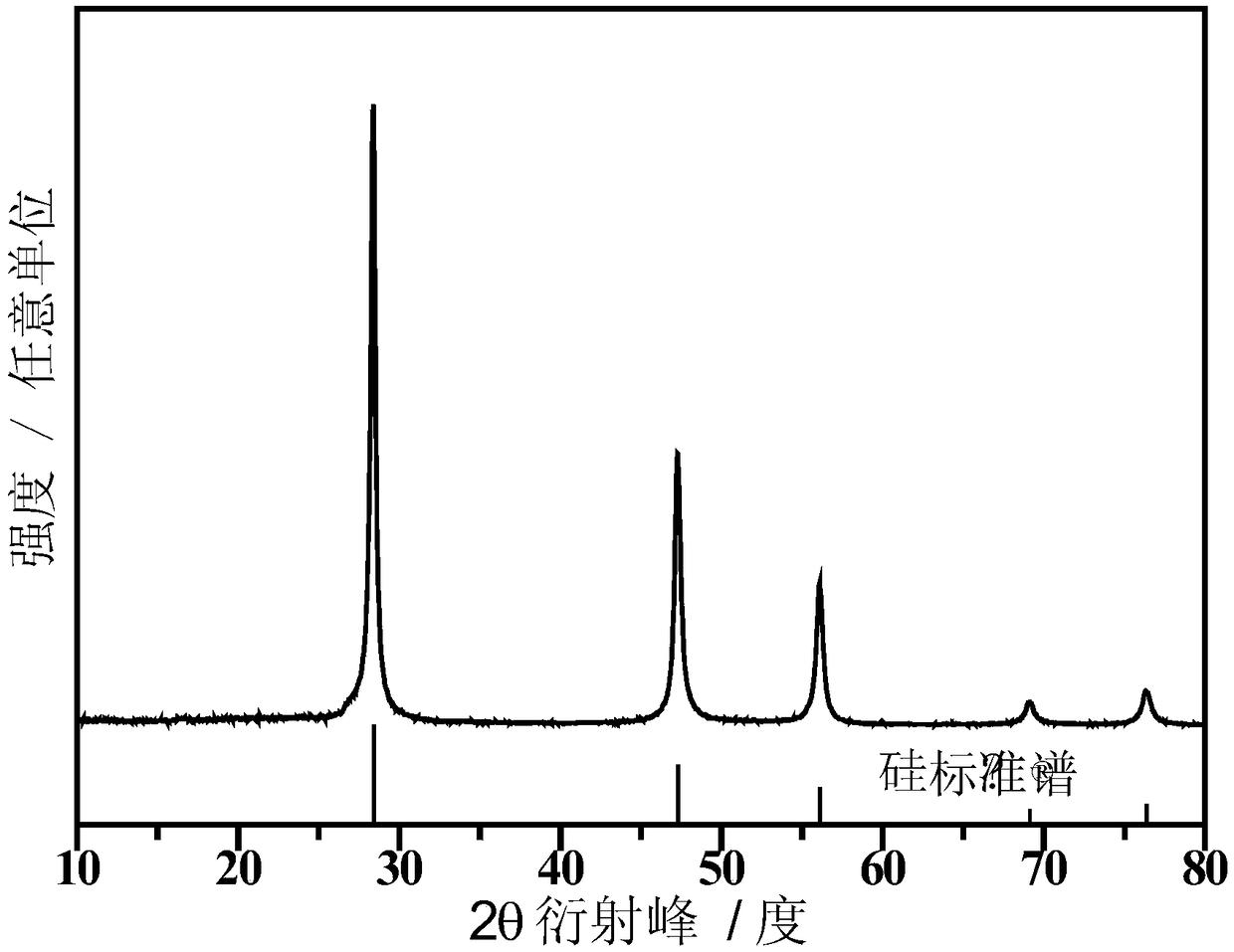

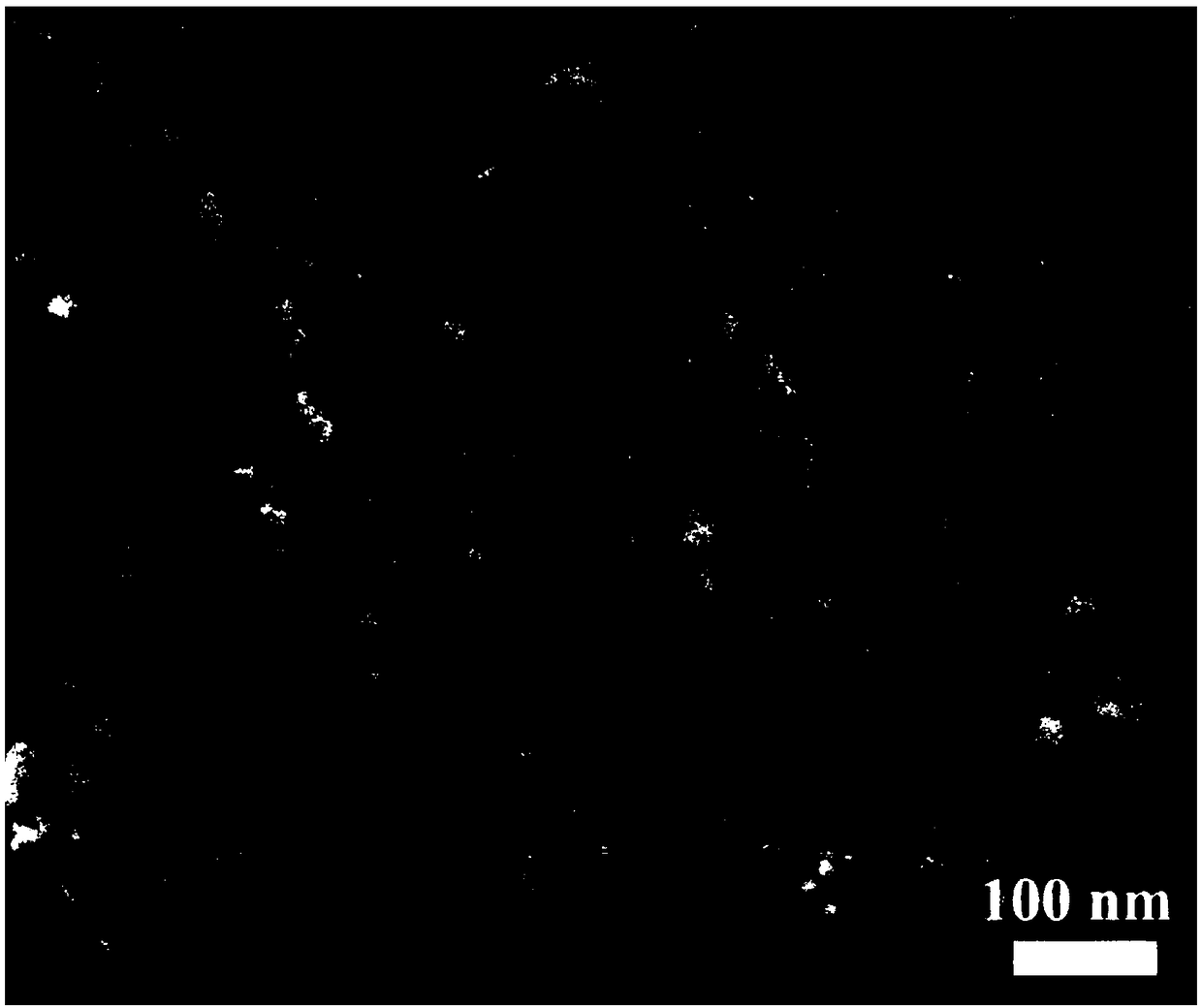

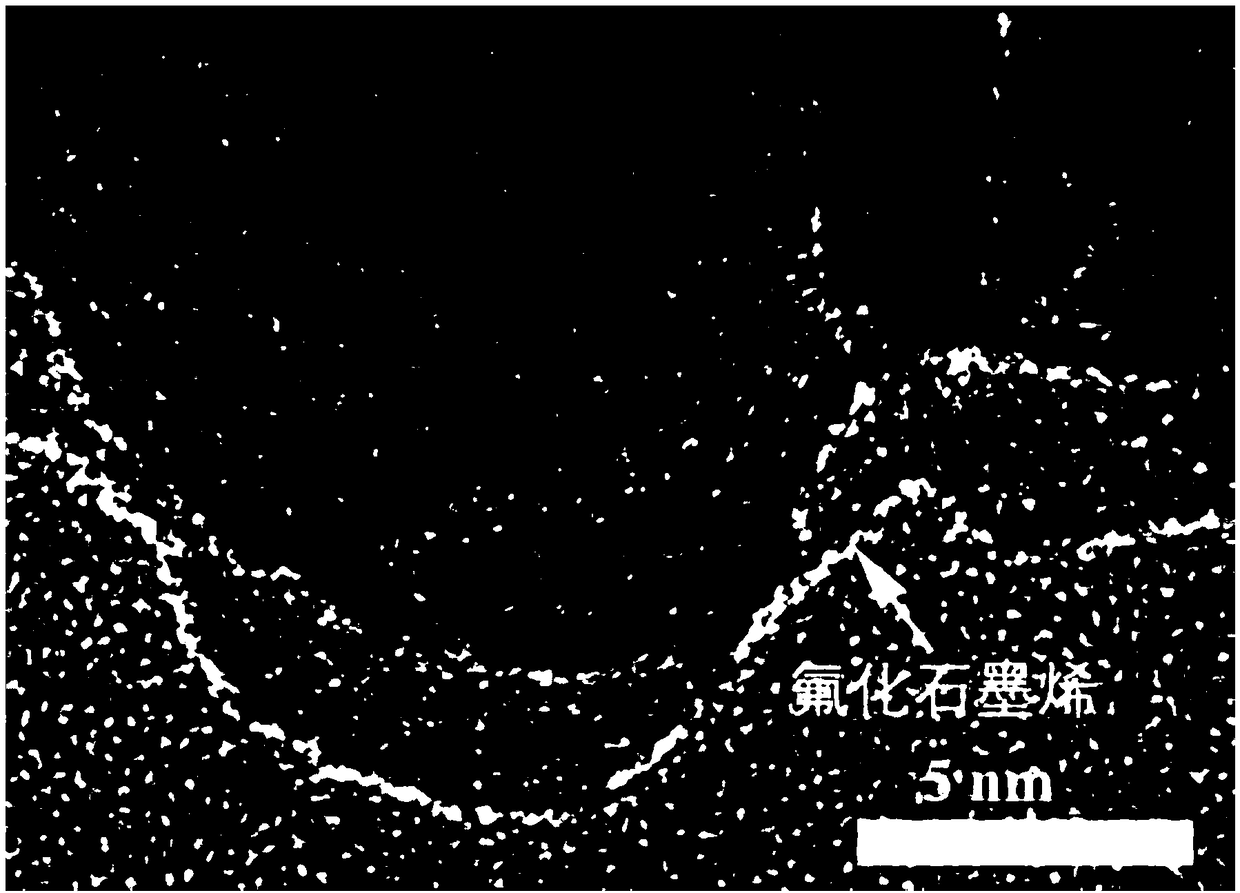

[0057] Commercial crude silicon was ball-milled at 480r / min for 10 hours, washed with 0.1mol / L hydrochloric acid, and then heat-treated at 600°C for 3 hours in an argon atmosphere to preliminarily crush and purify the crude silicon; Coarse silicon and magnesium powder are mixed uniformly according to the molar ratio of silicon and magnesium of 1:2.04, and heat treated in an argon atmosphere at 650°C for 5 hours to obtain a magnesium silicide alloy; place the magnesium silicide alloy obtained above in a magnetic boat, and place polypropylene In another magnetic boat, wherein the weight ratio of polypropylene and magnesium silicide is 0.5:1, put the two magnetic boats in a tube furnace, heat up to 800°C under an argon atmosphere, and then heat-treat in an argon atmosphere at 800°C After 20 hours, cool naturally to room temperature to obtain a silicon-carbon nano-composite material; the above-mentioned gained nano-silicon-carbon composite material is mixed with fluorinated graphen...

Embodiment 2

[0079] Commercial crude silicon was ball-milled at 480r / min for 10 hours, washed with 0.1mol / L hydrochloric acid, and then heat-treated at 600°C for 3 hours in an argon atmosphere to preliminarily crush and purify the crude silicon; Coarse silicon and magnesium powder are mixed uniformly according to the molar ratio of silicon and magnesium of 1:2.06, and heat-treated in an argon atmosphere at 550°C for 15 hours to obtain a magnesium-silicon alloy; place the magnesium silicide alloy obtained above in a magnetic boat, and place polyethylene In another magnetic boat, wherein the weight ratio of polyethylene and magnesium silicide is 1:1, put the two magnetic boats in a tube furnace, heat up to 750°C under an argon atmosphere, and then heat-treat in an argon atmosphere at 750°C After 30 hours, cool naturally to room temperature to obtain a silicon-carbon nanocomposite material; mix the nano-silicon-carbon composite material obtained above with fluorinated carbon fiber, wherein the...

Embodiment 3

[0084] Commercial crude silicon was ball-milled at 480r / min for 10 hours, washed with 0.1mol / L hydrochloric acid, and then heat-treated at 600°C for 3 hours in an argon atmosphere to preliminarily crush and purify the crude silicon; Coarse silicon and magnesium powder are mixed uniformly according to the molar ratio of silicon and magnesium of 1:2.02, and heat-treated in an argon atmosphere at 600°C for 10 hours to obtain a magnesium-silicon alloy; the magnesium silicide alloy obtained above is placed in a magnetic boat, and polyethylene is placed In another magnetic boat, wherein the weight ratio of polyvinyl chloride and magnesium silicide is 2:1, the two magnetic boats are placed in a tube furnace, and the temperature is raised to 850 ° C under an argon atmosphere, and then heated at 850 ° C in an argon atmosphere Heat treatment for 15 hours, and naturally cool to room temperature to obtain a silicon-carbon nanocomposite material; mix the nano-silicon-carbon composite materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com