A method and an application of a fluorocarbon additive for lithium sulfide battery

A lithium-sulfur battery and carbon fluoride technology, applied in secondary batteries, battery electrodes, battery recycling, etc., can solve problems such as volume expansion, low Coulombic efficiency, and fast specific capacity decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

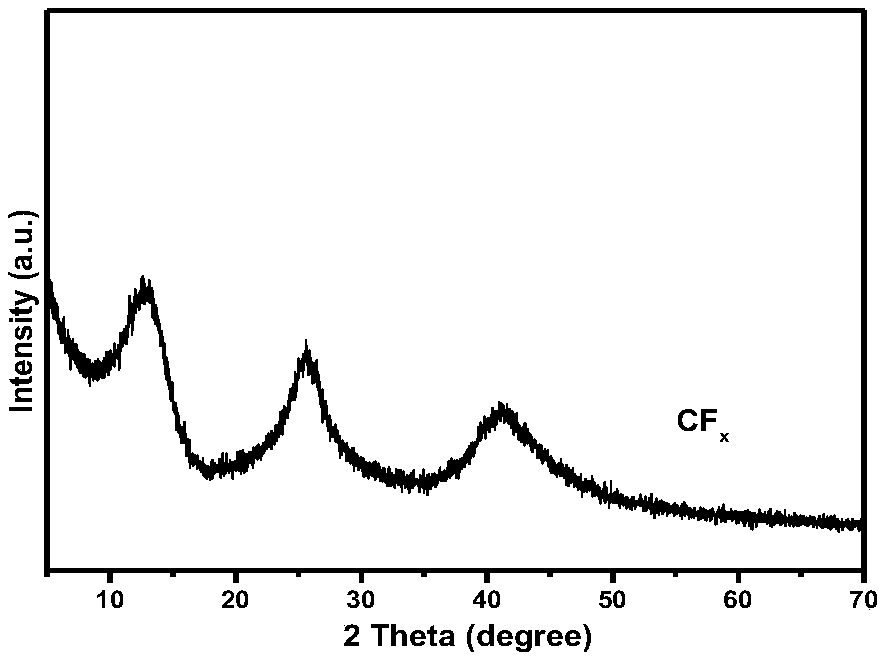

Method used

Image

Examples

Embodiment 1

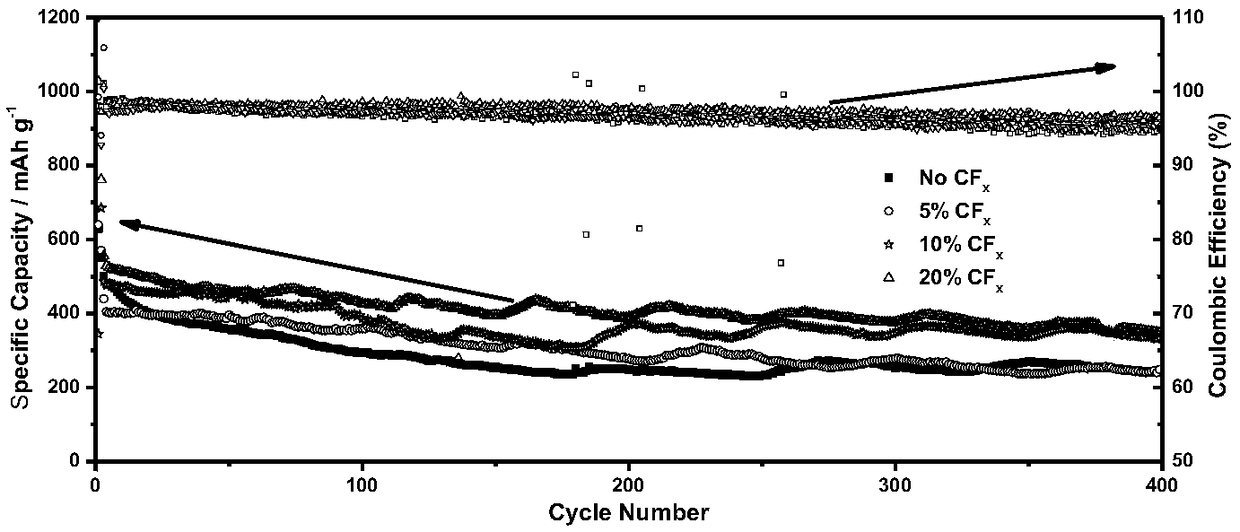

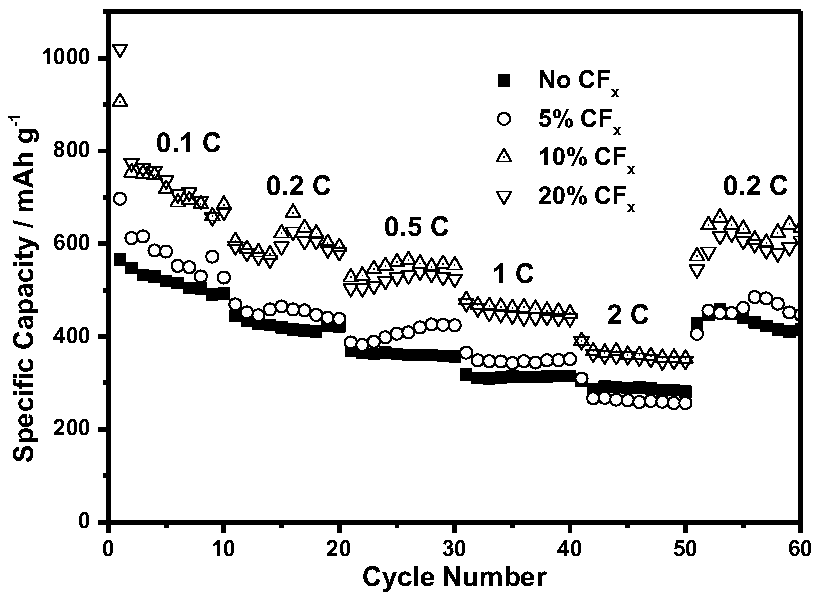

[0025] Weigh 5mg of carbon fluoride, 70mg of sulfur, 20mg of conductive agent Super P, and 10mg of polyvinylidene fluoride, mix them evenly in the solvent N-methylpyrrolidone, and evenly coat them on the carbon-coated aluminum foil, and then put the prepared electrode sheet Dry in an ordinary drying oven at 60°C for 12h, and then transfer to a vacuum oven at 60°C for 12h. With metal lithium sheet as negative electrode, 1.0M LiTFSI, 5% LiNO 3 DME: DOL = 1: 1Vol% is the electrolyte, the separator uses a commercial Celgar 2400 separator, the battery case model is 2025, and the button cell is assembled in a glove box (oxygen content is less than 0.5ppm, water content is less than 0.5ppm).

[0026] After the battery assembly is completed, the rate charge and discharge cycle test is performed on the battery tester (Wuhan Landian Battery Test System), the working voltage is 1.8-3V, and the data is collected and drawn and analyzed by origin data processing software.

[0027] When the...

Embodiment 2

[0029] Weigh 10mg of carbon fluoride, 70mg of sulfur, 20mg of conductive agent Super P, and 10mg of polyvinylidene fluoride in the solvent N-methylpyrrolidone and mix them evenly, and evenly coat them on the carbon-coated aluminum foil, and then put the prepared electrode sheet Dry in an ordinary drying oven at 60°C for 12h, and then transfer to a vacuum oven at 60°C for 12h. With metal lithium sheet as negative electrode, 1.0M LiTFSI, 5% LiNO 3 DME: DOL = 1: 1Vol% is the electrolyte, the separator uses a commercial Celgar 2400 separator, the battery case model is 2025, and the button cell is assembled in a glove box (oxygen content is less than 0.5ppm, water content is less than 0.5ppm).

[0030] After the battery assembly is completed, the rate charge and discharge cycle test is performed on the battery tester (Wuhan Landian Battery Test System), the working voltage is 1.8-3V, and the data is collected and drawn and analyzed by origin data processing software.

[0031] When...

Embodiment 3

[0033] Weigh 20mg of fluorinated carbon, 70mg of sulfur, 20mg of conductive agent Super P, and 10mg of polyvinylidene fluoride in the solvent N-methylpyrrolidone and mix them evenly, and evenly coat them on the carbon-coated aluminum foil, and then put the prepared electrode sheet Dry in an ordinary drying oven at 60°C for 12h, and then transfer to a vacuum oven at 60°C for 12h. With metal lithium sheet as negative electrode, 1.0M LiTFSI, 5% LiNO 3 DME: DOL = 1: 1Vol% is the electrolyte, the separator uses a commercial Celgar 2400 separator, the battery case model is 2025, and the button cell is assembled in a glove box (oxygen content is less than 0.5ppm, water content is less than 0.5ppm).

[0034] After the battery assembly is completed, the rate charge and discharge cycle test is performed on the battery tester (Wuhan Landian Battery Test System), the working voltage is 1.8-3V, and the data is collected and drawn and analyzed by origin data processing software.

[0035] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com