Silicon-carbon particles used in the cathode of lithium batteries

A technology of silicon carbon particles and carbon particles, which is applied in the field of silicon material preparation, can solve the problems of the collapse of the silicon anode structure, pulverization, and the inability to recycle waste materials, and achieves the effects of stable electrical contact, stable bonding and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The method for preparing lithium battery negative electrode material by diamond wire cutting waste silicon powder comprises the following steps:

[0045] 1) Remove the collected crystalline silicon diamond wire cutting waste silicon powder from metal, polyethylene glycol, glue, glass and other impurities remaining in the crystalline silicon diamond wire cutting waste silicon powder.

[0046] 2) Prepare mixed solution: use 0.3mol / L hydrochloric acid, 40% sulfuric acid and 45% nitric acid to prepare a mixed solution, wherein the volume ratio of hydrochloric acid, sulfuric acid, and nitric acid is 1:0.8:1; The temperature is 80°C.

[0047]3) Soak diamond wire cutting waste silicon powder in the mixed solution for 6 hours with vacuum stirring to remove metal copper, iron, nickel plasma and at the same time conduct preliminary corrosion on the surface of diamond wire cutting waste silicon powder particles, and then use Rinse 5 to 20 times with DI water and ethanol mixture b...

Embodiment 2

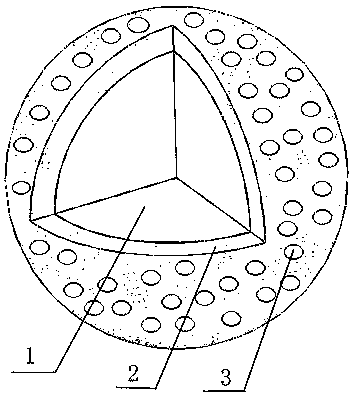

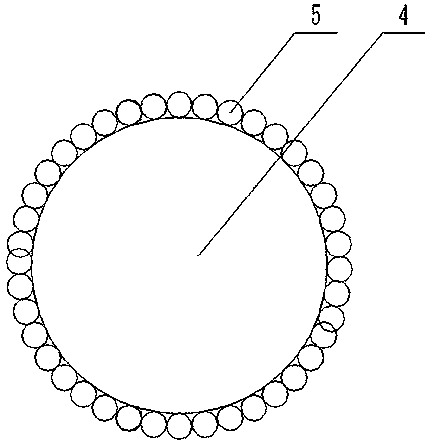

[0057] Such as image 3 As shown, the preparation method of the silicon-carbon particles is the same as in Example 1. The silicon-carbon particles used for the negative electrode of a lithium battery include spherical carbon particles 4 and spherical silicon particles 5, and the particle size of the silicon particles 5 is 50 mm. The particle size of the carbon particle 4 is 200nm, and the surface layer of the carbon particle 4 is connected with several silicon particles 5 ; the multiple silicon particles 5 wrap the surface of the carbon particle 4 . Among them, the spherical silicon particles 5 include a spherical elemental silicon inner core 1 , the surface of the spherical elemental silicon inner core 1 is covered with a silicon oxide outer layer 2 , and a plurality of holes 3 are distributed through the silicon oxide outer layer 2 . The radius ratio of the elemental silicon inner core 1 to the silicon oxide outer layer 2 is 1:1.5.

Embodiment 3

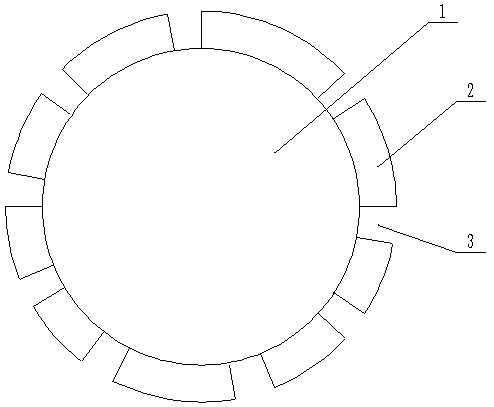

[0059] Such as Figure 4 As shown, the preparation method of the silicon-carbon particles is the same as in Example 1. The silicon-carbon particles used for the negative electrode of a lithium battery include spherical carbon particles 4 and spherical silicon particles 5, and the particle size of the silicon particles 5 is 30 mm. The particle size of the carbon particles 4 is 30nm, and the carbon particles 4 and the silicon particles 5 are alternately connected in the horizontal and vertical spaces. Among them, the spherical silicon particles 5 include a spherical elemental silicon inner core 1 , the surface of the spherical elemental silicon inner core 1 is covered with a silicon oxide outer layer 2 , and a plurality of holes 3 are distributed through the silicon oxide outer layer 2 . The ratio of the radii of the elemental silicon inner core 1 to the outer silicon oxide layer 2 is 1:1.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com