Preparation method of porous silica coated Co-N-C hollow nanotube material and application thereof

A silica, loose and porous technology, applied in chemical instruments and methods, catalyst activation/preparation, inorganic chemistry, etc., to achieve the effect of novel method, convenient synthesis process and post-treatment, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

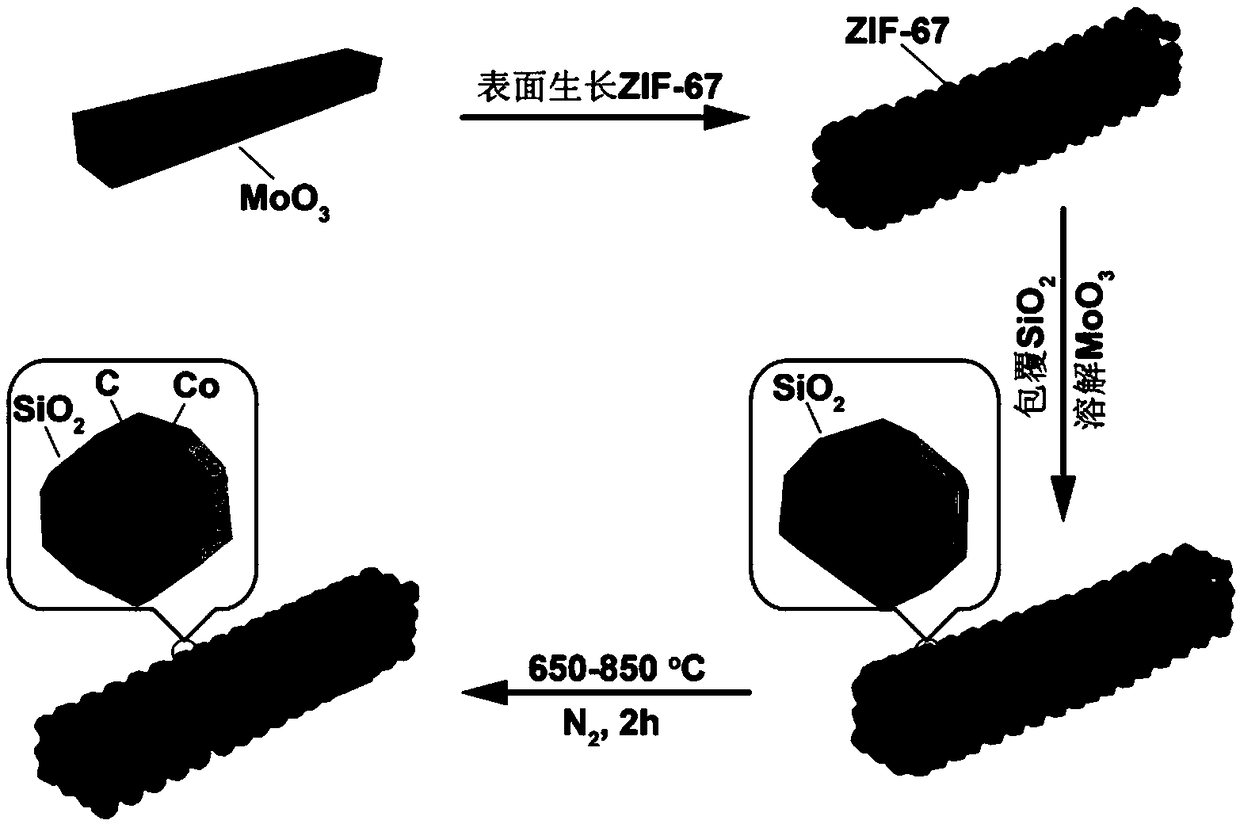

[0031] A kind of preparation method of porous silicon dioxide coating Co-N-C hollow nanotube material, comprises the following steps:

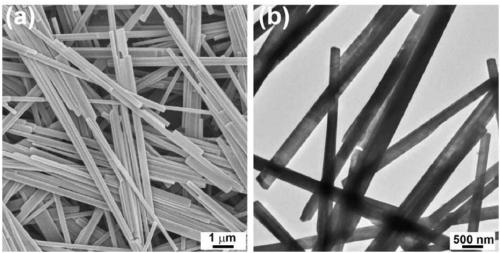

[0032] (1) Preparation of MoO 3 Nanorods (A1): Mix 6.665mL of nitric acid with 33.335mL of deionized water with a 1000mL pipette gun, then weigh 1.4g of ammonium molybdate, add the supernatant and stir for 20min, then transfer to a 100mL reactor, and react in an oven at 200°C 20h, centrifuge and wash after cooling to obtain MoO3 Drying, the SEM and TEM images are as follows figure 2 (a), figure 2 As shown in (b), it can be seen from the figure that the obtained MoO 3 It is a solid nanorod structure with a diameter of 300nm;

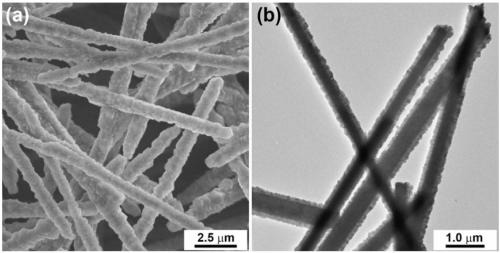

[0033] (2) Preparation of MoO 3 @ZIF-67 Nanorod (A2): Weigh 4.5982g 2-methylimidazole and dissolve it in 280mL methanol, and add 0.5g MoO after it is completely dissolved 3 After ultrasonic dispersion was uniform, 140 mL of 0.03 g / mL Co(NO 3 ) 2 Methanol solution, let stand at room temperature for 3h, centrifuge ...

Embodiment 2

[0039] Application of loose and porous silica-coated Co-N-C hollow nanotubes in catalytic hydrogen production from ammonia borane

[0040] First, 10mg Co-N-C@SiO 2 The catalyst was pretreated with freshly prepared 10 mL of ammonia borane (AB) aqueous solution at a concentration of 3.3 mg / mL in a 25 mL double-neck round bottom flask for 12 min to improve the Co-N-C@SiO 2 of dispersion. One port is then sealed with a rubber cap and the other port is connected with a gas collection system. Then, 0.5 mL of AB aqueous solution with a concentration of 66 mg / mL was quickly injected into the reaction system under vigorous stirring at 1000 rpm. Gases generated by hydrolysis are measured by a typical water displacement method. The durability cycle test is to add another equivalent amount of 0.5mL AB aqueous solution with a concentration of 66mg / mL to the reaction system after the reaction of the added AB solution is complete, and then collect and measure the released hydrogen gas aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com