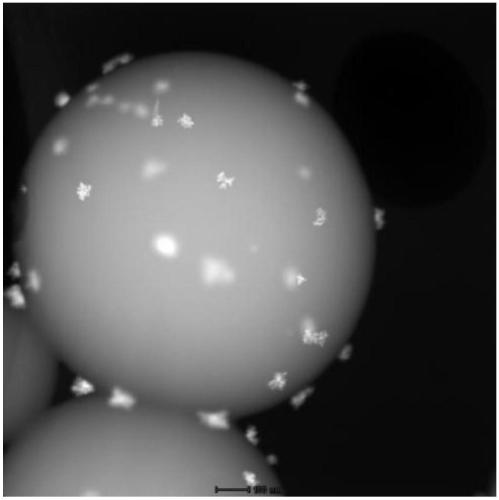

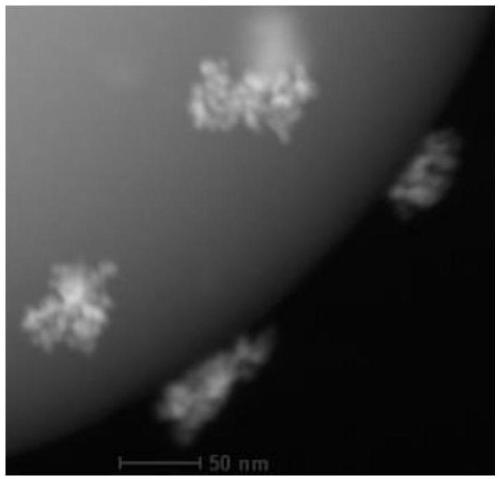

Compound catalyst with palladium and surface-functionalized carbon quantum dots carried by mesoporous carbon microsphere, preparation method and application of compound catalyst

A surface functionalization and composite catalyst technology, which is applied in the preparation of hydroxyl compounds, organic compound/hydride/coordination complex catalysts, and organic compound preparation, can solve the problems of increasing equipment and catalyst costs, low selectivity, and complicated operation and other issues, to achieve the effect of improving selectivity and conversion rate and the rate of selective hydrogenation reaction, accelerating electron transport, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

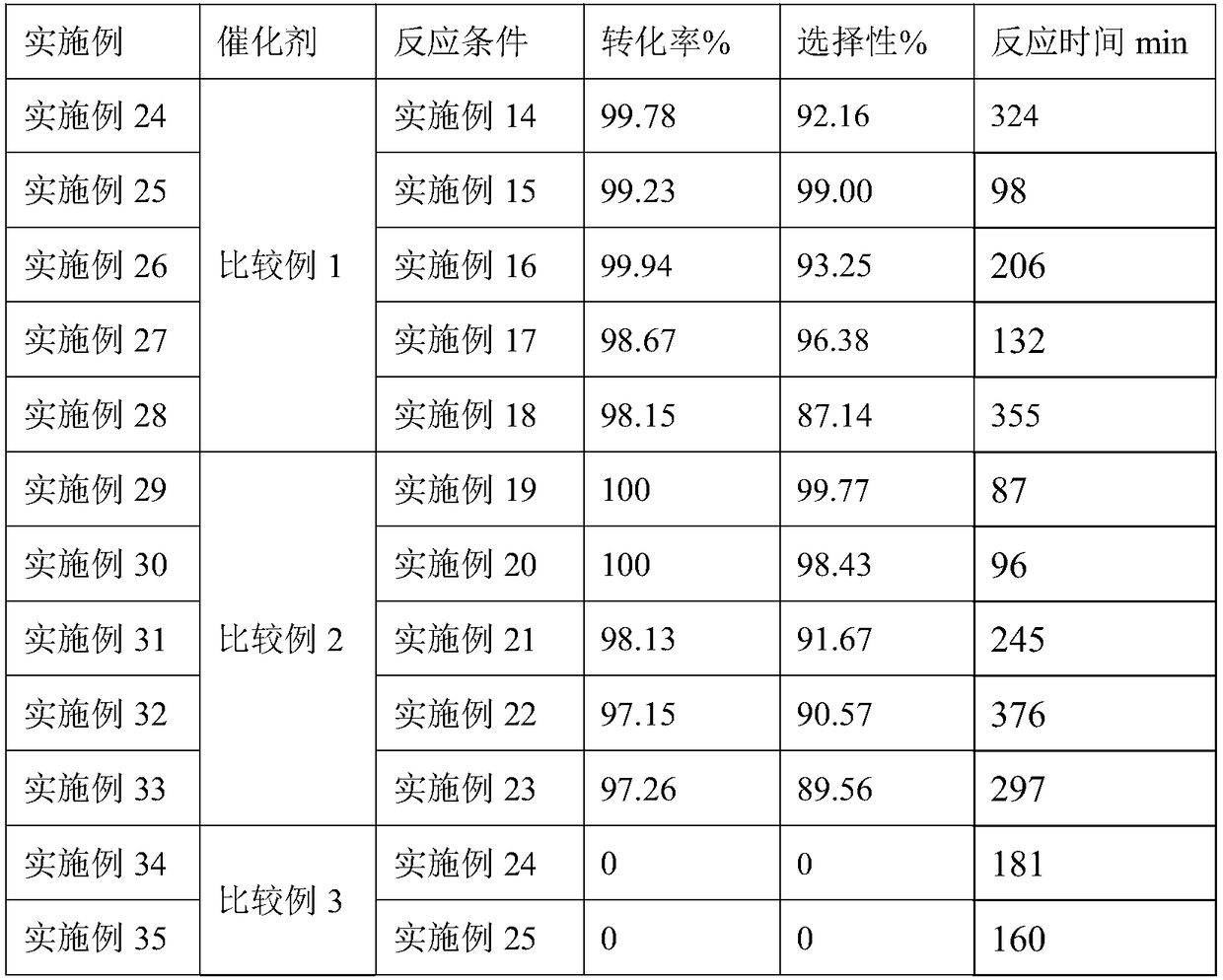

Examples

Embodiment 1

[0034] Take 65ml of deionized water, 25ml of ethanol, 0.2g of F 127, and 1ml of ammonia solution with a mass concentration of 25-28%, and mix and stir for 1 hour until the F 127 is completely dissolved. Then add 3.2g of 3-aminophenol and continue to stir for 0.5h until the 3-aminophenol is completely dissolved. Add 4ml of 37-40% formaldehyde solution slowly, and stir for 24h. Then stop stirring and heat at 100°C for 24h. Then filter and dry at 60°C to obtain brick-red solid powder, namely: polymer microspheres.

[0035] Take 1g of citric acid, 10ml of deionized water, and 0.2g of ethylenediamine, put them in a hydrothermal kettle, and heat them at 200°C for 10 hours, then take out the hydrothermal samples and set the volume to a 100ml volumetric flask to obtain surface functionalization aqueous solution of carbon quantum dots. Afterwards, 50ml of carbon quantum dot aqueous solution was taken out for dialysis, and a dialysis bag of a certain length was first cut and boiled i...

Embodiment 2

[0039] Take 60ml of deionized water, 28ml of ethanol, 0.8g of F 127, and 0.8ml of ammonia solution with a mass concentration of 25-28%, and mix and stir for 0.5h until the F 127 is completely dissolved. Then add 3.5g of 3-aminophenol and continue to stir for 1h until the 3-aminophenol is completely dissolved. Then slowly add 6ml of 37-40% formaldehyde solution and stir for 12h. Then stop stirring and heat at 100°C for 24h. Then filter and dry at 80°C to obtain brick-red solid powder, that is, polymer microspheres.

[0040] Take 5g of citric acid, 15ml of deionized water, 0.05g of urea and 0.05g of ammonia water, put them into a hydrothermal kettle, heat at 190°C for 11 hours, then take out the sample after hydrothermal treatment and dilute it to a 250ml volumetric flask to obtain the surface Functionalized carbon quantum dots in aqueous solution. Afterwards, 50ml of carbon quantum dot aqueous solution was taken out for dialysis, and a dialysis bag with a molecular weight cu...

Embodiment 3

[0044] Take 80ml of deionized water, 26ml of ethanol, 1.5g of F 127, and 0.5ml of ammonia solution with a mass concentration of 25-28%, and mix and stir for 2 hours until the F 127 is completely dissolved. Then add 2.8g of 3-aminophenol and continue to stir for 2h until the 3-aminophenol is completely dissolved. Slowly add 5ml of 37-40% formaldehyde solution and stir for 48h. Then stop stirring, and heat at 100°C for 48h. Then filter and dry at 70°C to obtain a brick-red solid powder, that is, polymer microspheres.

[0045] Take 0.5g of citric acid, 12ml of deionized water, and 0.3g of glycine, put them in a hydrothermal kettle, heat at 180°C for 12h, then take out the hydrothermally heated sample and set the volume to a 250ml volumetric flask to obtain surface functionalized Aqueous solution of carbon quantum dots. Afterwards, 100ml of carbon quantum dot aqueous solution was taken out for dialysis, and a certain length of dialysis bag with a molecular weight cut-off of 700...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com