Cold core box ceramsite sand and preparation method thereof

A technology of ceramsite sand and cold box, applied in the direction of core, manufacturing tools, casting molding equipment, etc., can solve the problems of large thermal expansion, large angle coefficient, large binder, etc., to maintain roundness and flow properties, improving fire resistance, and reducing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

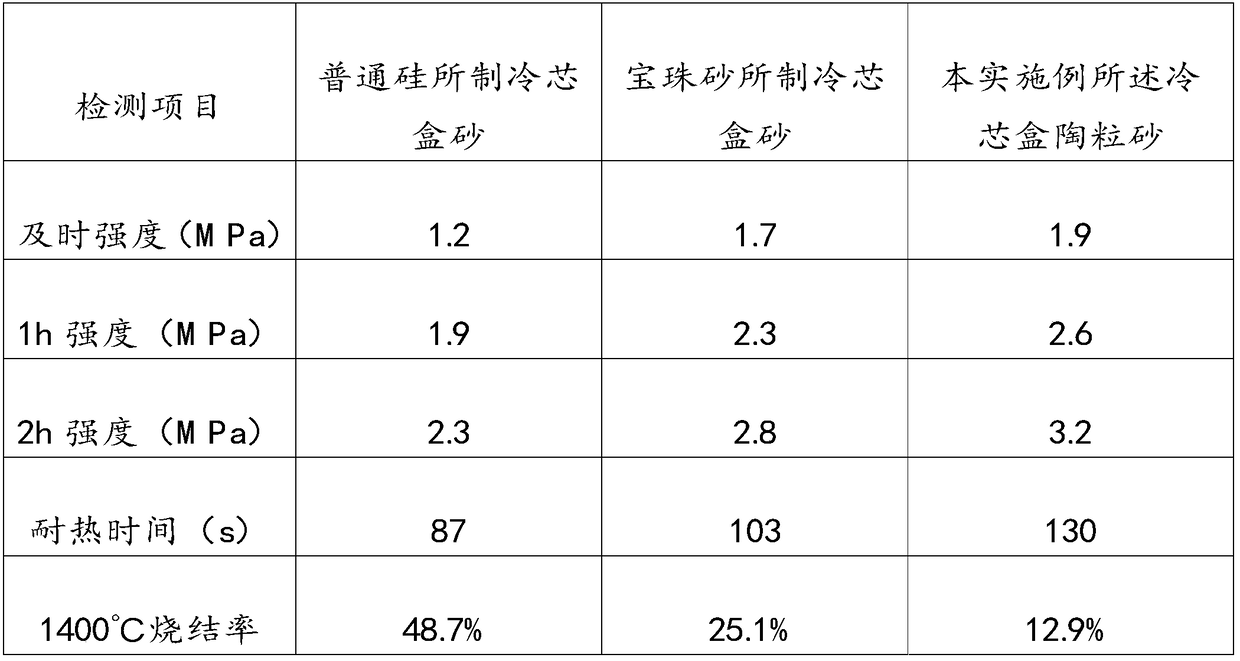

Examples

Embodiment 1

[0034] A cold box ceramsite sand, comprising the following raw materials in parts by weight: 80kg of ceramsite sand, 5kg of ferroferric oxide, 0.1kg of zeolite powder, and 1kg of organic resin;

[0035] The organic resin is composed of the following raw materials: 50 g of phenolic resin and 40 g of polyisocyanate.

[0036] The preparation method of the cold box ceramsite sand includes the following steps:

[0037] (1) Preparation of ceramsite sand;

[0038] (2) Crush the ceramsite sand, ferroferric oxide, zeolite powder and organic resin separately, mix and stir them evenly, and add them into the cold core box; pass triethylamine gas into the cold core box to obtain the cold core Box of ceramsite sand.

Embodiment 2

[0040] A cold box ceramsite sand, comprising the following raw materials by weight: 90kg of ceramsite sand, 7kg of ferroferric oxide, 0.8kg of zeolite powder, and 2kg of organic resin;

[0041] The organic resin is composed of the following raw materials: 50 g of phenolic resin and 40 g of polyisocyanate.

[0042] The preparation method of the cold box ceramsite sand includes the following steps:

[0043] (1) Prepare ceramsite sand; pulverize clay, slate, shale or coal gangue; add the raw materials obtained after pulverization into a granulator for granulation, after the granulation is completed, add aluminum powder to the granulator , Mixing and stirring uniformly to obtain a spherical semi-finished product coated with aluminum powder, and sintering the spherical semi-finished product coated with aluminum powder to obtain the ceramsite sand.

[0044] (2) Crush the ceramsite sand, ferroferric oxide, zeolite powder and organic resin separately, mix and stir them evenly, and add them in...

Embodiment 3

[0046] A cold box ceramsite sand, comprising the following raw materials in parts by weight: 100kg of ceramsite sand, 8kg of ferroferric oxide, 1kg of zeolite powder, and 2kg of organic resin;

[0047] The organic resin is composed of the following raw materials: 55 g of phenolic resin and 50 g of polyisocyanate.

[0048] The preparation method of the cold box ceramsite sand includes the following steps:

[0049] (1) Prepare ceramsite sand; crush clay, slate, shale or coal gangue into particles with a fineness of 500 mesh; add the raw materials obtained after crushing into a granulator for granulation, and after the granulation is completed, Add aluminum powder with a fineness of 600 mesh to the granulator, mix and stir evenly to obtain a spherical semi-finished product coated with aluminum powder, and sinter the spherical semi-finished product coated with aluminum powder at a temperature of 1000°C for 25 minutes to obtain the Ceramsite sand.

[0050] (2) Crush the ceramsite sand, fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com