Preparation method of patterned metal film

A patterned metal and metal thin film technology, which is applied in metal material coating technology, gaseous chemical plating, and manufacturing microstructure devices, etc., can solve problems that are not conducive to the health of experimenters, increase the cost of material preparation, and complicate the preparation process. , to achieve the effects of environmental protection in the preparation process, reduction of chemical waste, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

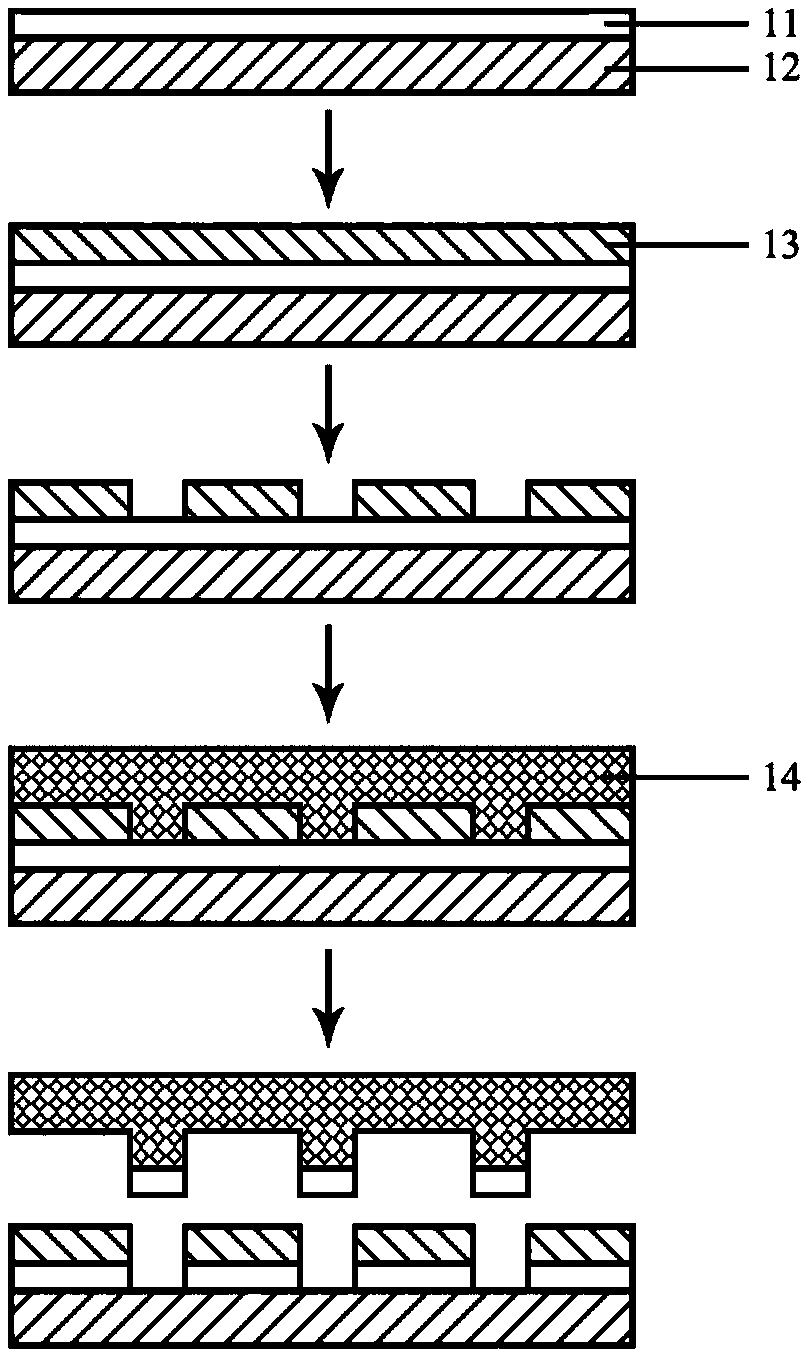

[0055] In conjunction with accompanying drawing, a kind of preparation method of patterned metal thin film comprises the following steps:

[0056] (1) Vacuum evaporation metal silver film

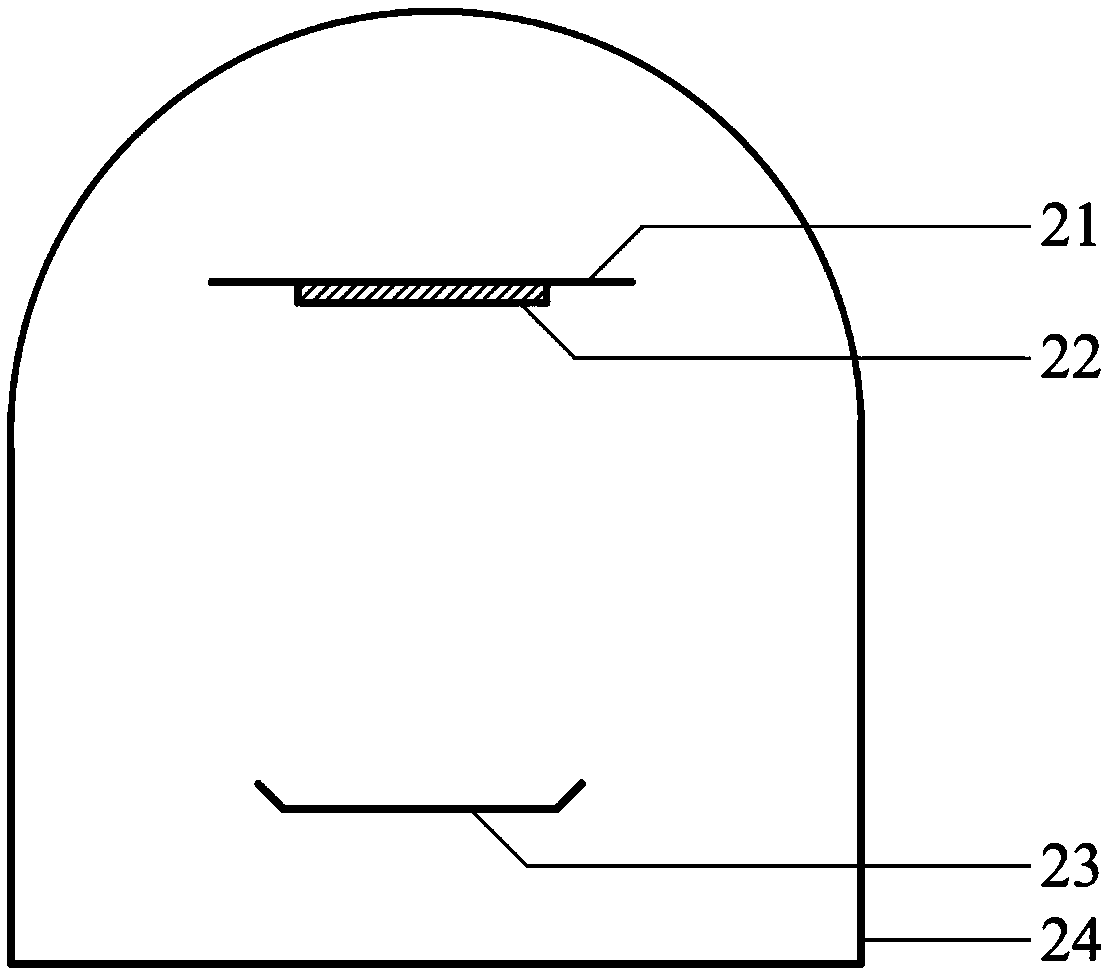

[0057] Turn on the cold water circulation system 21 of the vacuum evaporation device, fix the silicon substrate face down on the sample stage 22, place the metal silver target in the evaporation boat 23, and close the vacuum cover 24 to form a closed chamber. Evacuate the airtight chamber until the vacuum degree is less than 5×10 -4 Pa; after the pressure in the vacuum cover 24 reaches the required value, the evaporation boat 23 is heated and evaporated, the evaporation current is 120A, and the thickness of the metal silver film 11 is 10nm; The valve is deflated in the vacuum cover 24, then the vacuum cover is opened, and the sample of the vapor-deposited metallic silver film is taken out.

[0058] The above-mentioned vacuum evaporation device can adopt existing conventional equipment, su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com