Device and method for high-temperature smelting of metals and nonmetals

A smelting device, non-metal technology, applied in the directions of alkali metal/alkaline earth metal/beryllium/magnesium hydride, chemical instruments and methods, energy input, etc. problems, to achieve the effect of being conducive to environmental protection, reducing waste of resources, and improving the utilization rate of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

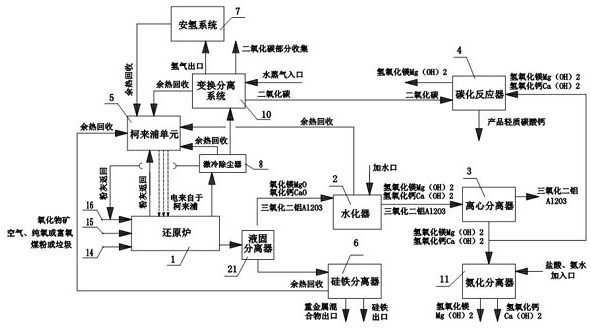

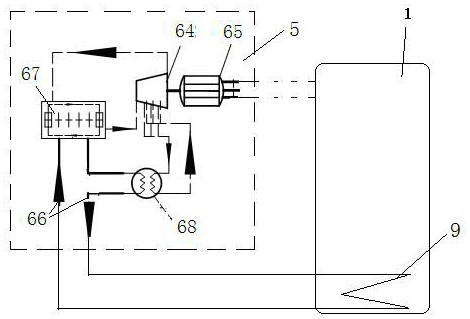

[0026] The high-temperature smelting device of metal and nonmetal of the present invention, such as figure 1 As shown, it includes a reduction furnace 1, a hydrator 2, a centrifugal separator 3, a liquid-solid separator 21, a carbonization reactor 4, a Collaps unit 5, a ferrosilicon separator 6, a conversion separation system 10, an ammoniation separator 11 and Anhydrogen system7. Such as Figure 4 As shown, the reduction furnace 1 is a rotary kiln structure, which is placed at an inclination of 5°. The rotary kiln is divided into a mixing combustion chamber 18, a preheating section 19 and a reduction section 20, and the mixing combustion chamber 18, preheating section 19 and reduction section 20 are connected in sequence. The mixed combustion chamber 18 is provided with a finished product outlet 13, a fuel and reducing agent inlet 14, an oxygen-enriched inlet 15, and a mineral inlet 16. The reduction section is provided with a carbon monoxide outlet 17, and the carbon monoxi...

Embodiment 2

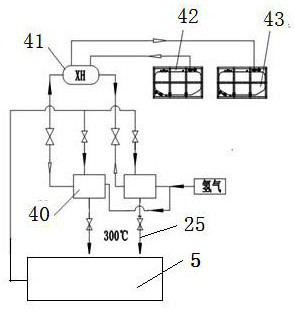

[0038] The high-temperature smelting device of metal and nonmetal of the present invention, such as Figure 5 As shown, it includes a reduction furnace 1, a Clapp unit 5, an hydrogen system 7, a chilling dust collector 8, a conversion separation system 10, a calcium carbide separator 12 and a calcium carbide product bin 22. The mixed combustion chamber 18 is provided with a finished product outlet 13, a fuel and reducing agent inlet 14, an oxygen-enriched inlet 15, and a mineral inlet 16. The reduction section is provided with a carbon monoxide outlet 17, which is connected to the chilled dust collector 8. The conversion separation system 10 is provided with a hydrogen outlet, a water vapor inlet, a carbon monoxide inlet and a carbon dioxide outlet. The hydrogen outlet is connected to the hydrogen safety system, the carbon monoxide inlet is connected to the outlet of the chilling dust collector 8, and all the carbon dioxide is collected and recycled. The finished product outle...

Embodiment 3

[0041] The high-temperature smelting device of metal and nonmetal of the present invention, such as Figure 6 As shown, it includes a reduction furnace 1, a Clapp unit 5, an hydrogen system 7, a chilling dust collector 8, a conversion separation system 10 and a warehouse 23 for finished metal iron. The mixed combustion chamber 18 is provided with a finished product outlet 13, a fuel and reducing agent inlet 14, an oxygen-enriched inlet 15, and a mineral inlet 16. The reduction section is provided with a carbon monoxide outlet 17, which is connected to the chilled dust collector 8. The conversion separation system 10 is provided with a hydrogen outlet, a water vapor inlet, a carbon monoxide inlet and a carbon dioxide outlet, the hydrogen outlet is connected to the hydrogen safety system, the carbon monoxide inlet is connected to the outlet of the chilling dust collector 8, and all the carbon dioxide is collected and recycled. The finished product outlet 13 of the reduction furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com