System and technology for zero discharging of high-salinity wastewater

A high-salt wastewater and zero-discharge technology, which is applied in the direction of water pollutants, water/sewage treatment, heating water/sewage treatment, etc., can solve problems such as environmental hazards, strong corrosion of solidified materials, and high treatment costs, and achieve high efficiency, energy saving and zero discharge. Emission treatment, good running stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

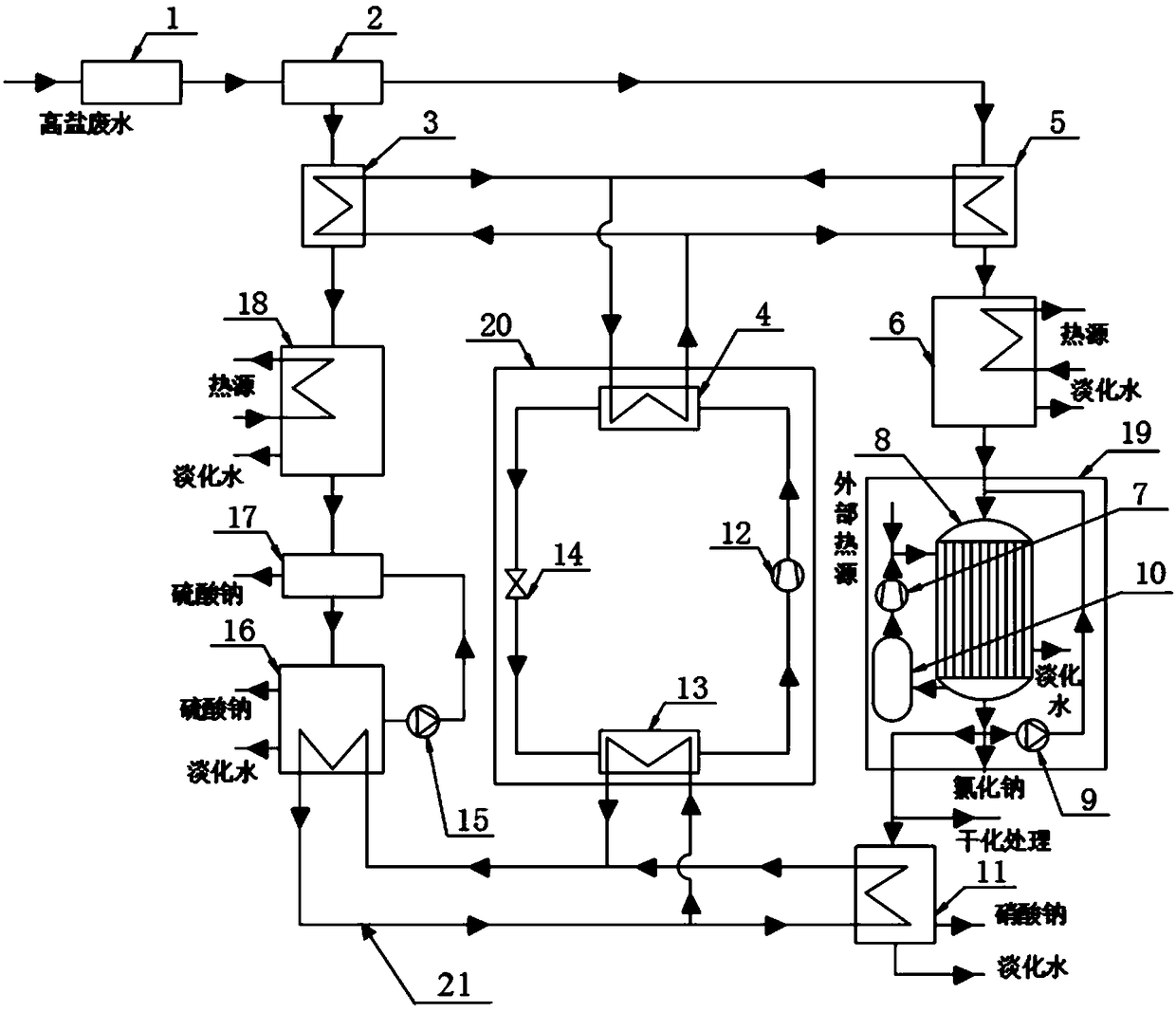

[0046] see figure 1 The schematic diagram of the system structure is the zero-discharge system for high-salt wastewater of the present invention, including a pretreatment device 1, a nanofiltration device 2, a second low-temperature multi-effect distillation device 18, a dissolution and crystallization desalination device 17, a low-temperature crystallization separation device 16, a second A low-temperature multiple-effect distillation device 6, a mechanical vapor recompression forced circulation evaporator 19, and a refrigeration system.

[0047]The fluid inlet end of described nanofiltration device 2 is connected with described pretreatment device 1 pipeline; The outlet end of the product water of 2 is connected with the pipeline of the first low-temperature multiple-effect distillation device 6;

[0048] The second low-temperature multiple-effect distillation device 18 is sequentially connected with the elution crystallization desalination device 17 and the low-temperature...

Embodiment 2

[0065] The present invention also provides a zero-discharge treatment process for high-salt wastewater, the specific steps of which are as follows:

[0066] Step S1: pretreatment of high-salt wastewater: pretreat the high-salt wastewater to be treated, so that the effluent meets the water quality standard for nanofiltration membrane separation;

[0067] Step S2: nanofiltration treatment: the wastewater pretreated in step S1 is treated by a nanofiltration device to obtain concentrated water and nanofiltration product water;

[0068] Step S3: Processing of nanofiltration product:

[0069] (4) The concentrated water in step S2 absorbs heat through low-temperature multi-effect distillation, evaporates and concentrates, and obtains evaporated desalinated water and further concentrated water;

[0070] (5) In the further concentrated water that step (1) obtains, add dissolution agent, to reduce the solubility of sodium sulfate, and then separate out sodium sulfate; Dissolution cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com