Method for preparing cementing material by using copper slag and steel slag as raw materials

A technology for cementitious material and copper slag is applied in the field of joint preparation of cementitious material from copper pyrometallurgical slag and converter steel slag, and can solve the problems of low hydration activity of copper slag, excessive silicate difference, and limited application of steel slag, etc. To achieve the effect of solving the problem of slag accumulation, reducing the amount of addition, good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

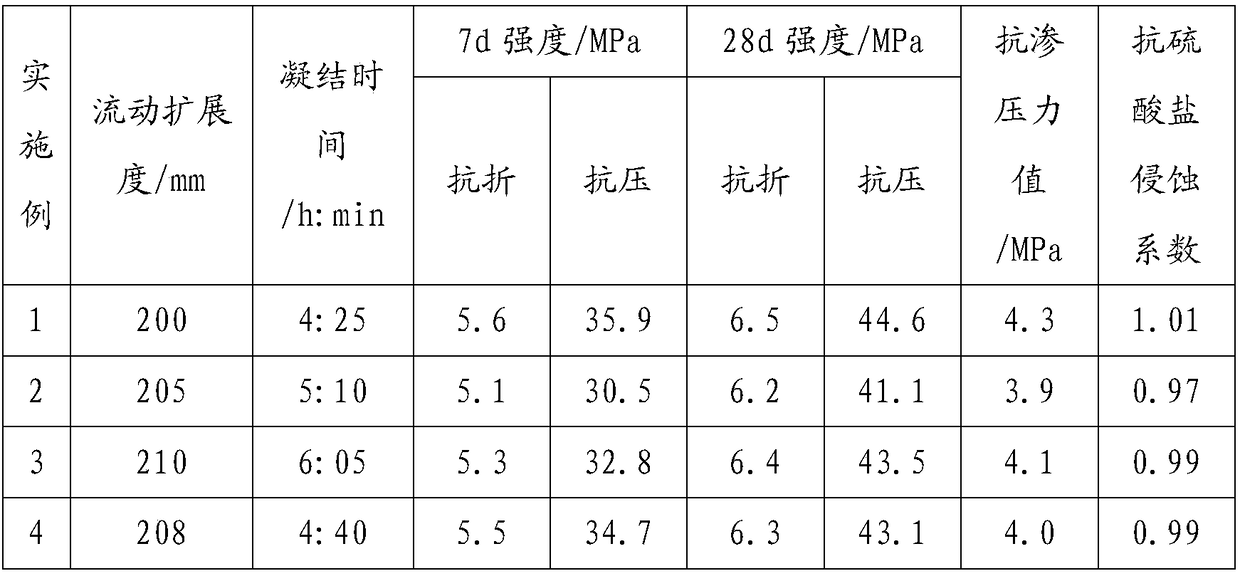

Embodiment 1

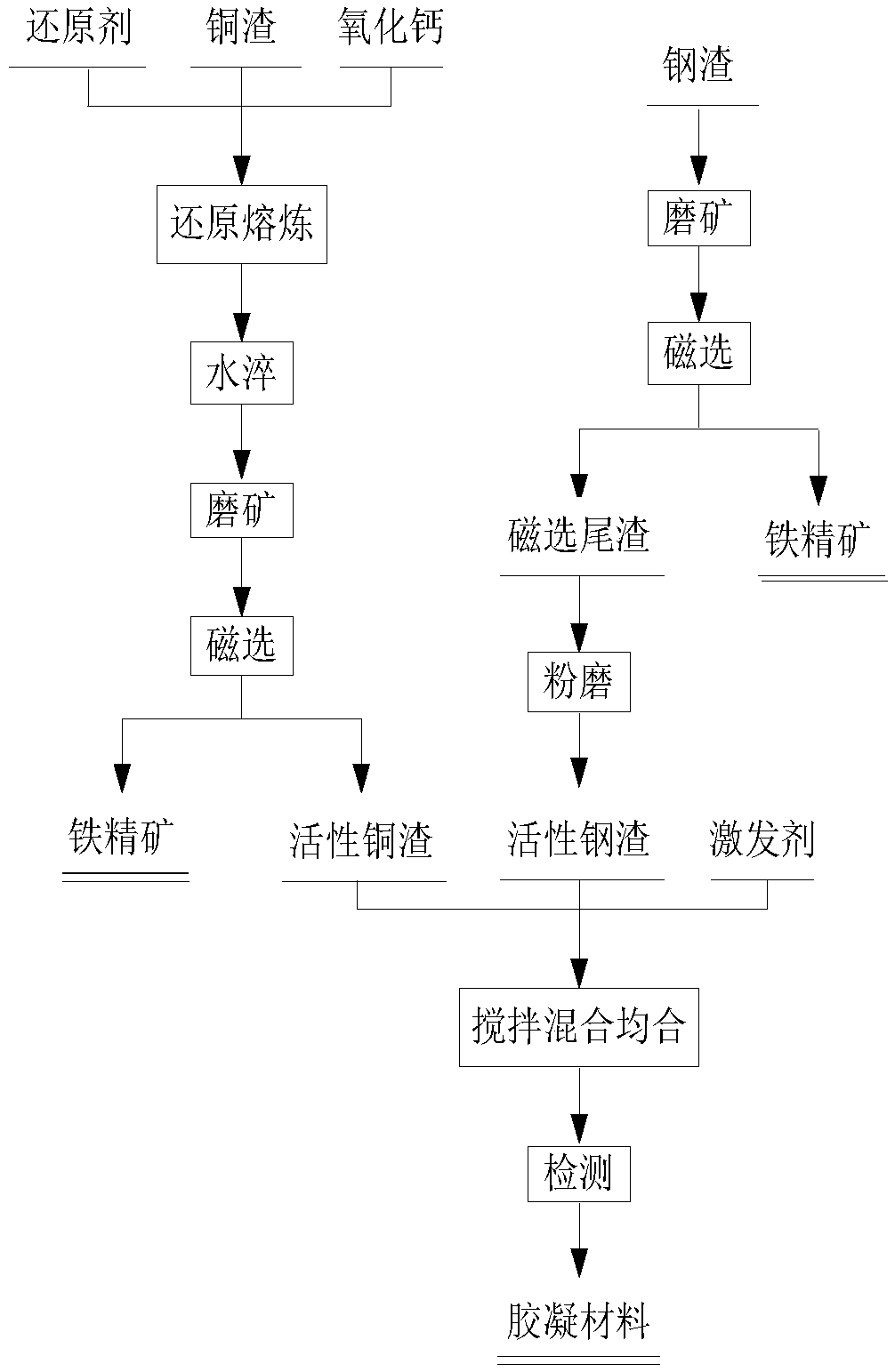

[0029] like figure 1 Shown, a kind of method for raw material preparation cementitious material with copper slag and steel slag, comprises the steps:

[0030] A. Copper slag activation. Take copper slag, reducing agent, and calcium oxide and mix them evenly, and reduce and smelt at 1300 ° C for 2 hours; the reducing agent is activated carbon, and the amount added is 20% of the mass of copper slag; the amount of calcium oxide added is 10% of the mass of copper slag; The obtained melt is directly cooled by water quenching, and then ground to less than 200 mesh P by ball milling 80 , and then under the condition that the magnetic induction intensity is 100mT, the iron concentrate is recovered by magnetic separation, and the tailings of the magnetic separation are activated copper slag, which is ready for use. Iron concentrate grade 65.5%.

[0031] B. Steel slag activation. Steel slag is ground to less than 200 mesh P 70 , under the condition of magnetic induction intensity o...

Embodiment 2

[0034] like figure 1 Shown, a kind of method for raw material preparation cementitious material with copper slag and steel slag, comprises the steps:

[0035] A. Copper slag activation. Take copper slag, reducing agent, and calcium oxide, mix them evenly, and reduce and smelt at 1500°C for 1 hour. In this embodiment, the reducing agent is activated carbon, its addition is 10% of the mass of copper slag, and the amount of calcium oxide is 20% of the mass of copper slag; the melt is ground to less than 200 mesh P 80 , and then under the condition that the magnetic induction intensity is 200mT, the iron concentrate is recovered by magnetic separation, the iron concentrate grade is 63.9%, and the magnetic separation tailings are activated copper slag, which is ready for use.

[0036] B. Steel slag activation. Steel slag is ground to less than 200 mesh P 70 , under the condition of magnetic induction intensity of 200mT, magnetic separation iron concentrate, iron concentrate gra...

Embodiment 3

[0039] like figure 1 Shown, a kind of method for raw material preparation cementitious material with copper slag and steel slag, comprises the steps:

[0040] A. Copper slag activation. Take copper slag, reducing agent, and calcium oxide, mix them evenly, and reduce and smelt at 1150°C for 3 hours. In this embodiment, the reducing agent is activated carbon, the amount added is 30% of the mass of copper slag, and the amount of calcium oxide is 5% of the mass of copper slag; the molten body is ground to less than 200 mesh P80 , and then recover iron ore concentrate by magnetic separation under the condition of magnetic induction intensity of 80mT, the grade of iron ore concentrate is 66.4%. The tailings of magnetic separation are activated copper slag, which is used as cementing raw material for future use.

[0041] B. Steel slag activation. Steel slag is ground to less than 200 mesh P 70 , Under the condition of magnetic induction intensity of 80mT, the iron concentrate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com