A kind of low-voc epoxy primer and preparation method thereof

A technology of epoxy primer and epoxy resin, which is applied in the field of coatings, can solve the problems of heat and humidity resistance, poor temperature resistance, and easy settlement of fillers, etc., and achieve excellent heat and humidity resistance and temperature resistance, high solid content in construction, Effect of Good Air Spray Gun Spray Workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

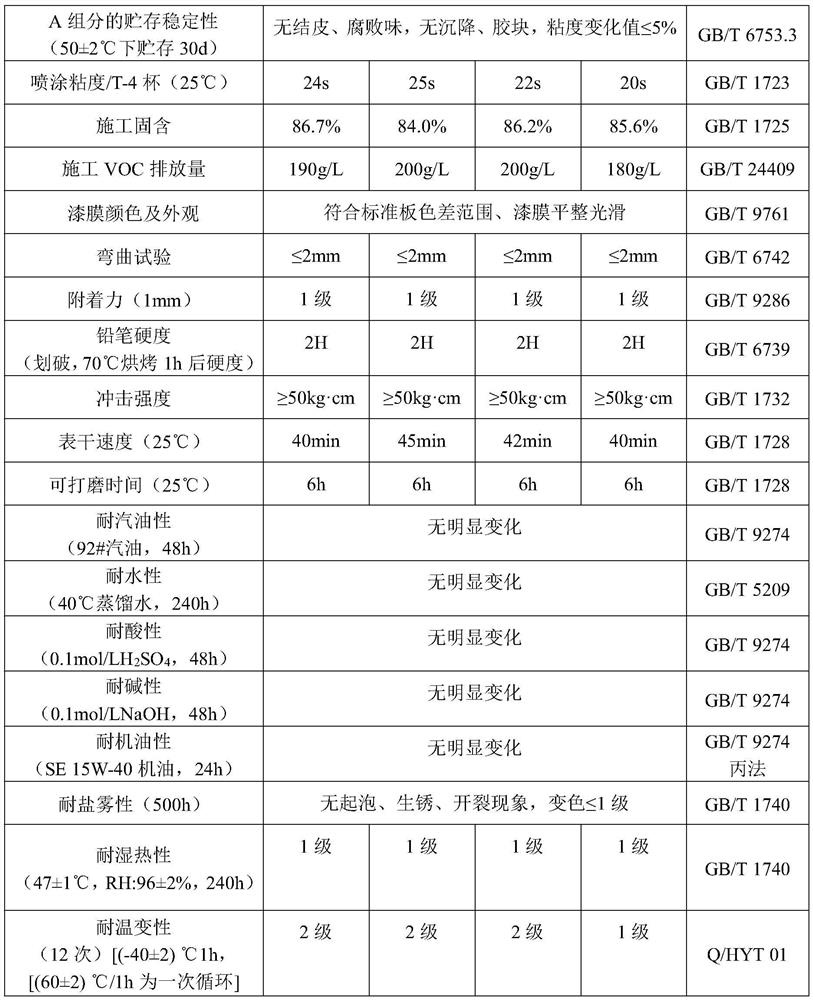

Embodiment 1~4

[0040] The preparation method of embodiment 1~4 epoxy primer is as follows:

[0041] S1. Preparation of component A: Take the formulated amount of xylene and n-butanol and mix, then add the formulated amount of bisphenol A epoxy resin E51, liquid petroleum resin and Lubrizol 20000 dispersant, stir for 5 minutes, then add the formulated amount A certain amount of organic bentonite, zinc molybdate, aluminum tripolyphosphate and barium sulfate, stirred for 10 minutes, then added the formula amount of allyl polyoxyalkylene epoxy ether, stirred for 10 min, finally added the formula amount of iron oxide black, mica Powder and talcum powder, after stirring for 20 minutes, enter the machine and grind until the fineness is ≤35um, and discharge the material to obtain component A; there is no large amount of air bubbles during the grinding process, and the process is smooth;

[0042] S2. Preparation of component B: Take the formula quantity of xylene and n-butanol and mix, add the formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com