Monomer with the same charge associating polymer composite oil displacement agent and alternate injection flooding method

A compound oil displacement agent and alternate injection technology, which is applied in the direction of drilling compositions, chemical instruments and methods, and production fluids, can solve problems such as difficult to significantly increase oil recovery, and achieve increased fluidity controllable range, The effect of improving oil displacement efficiency and increasing hydrophobic association strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

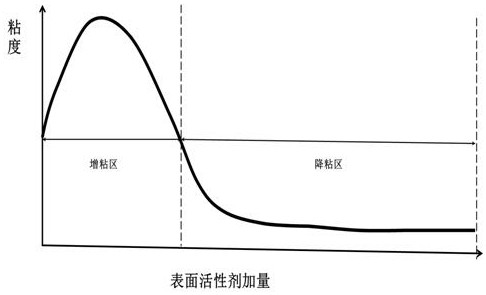

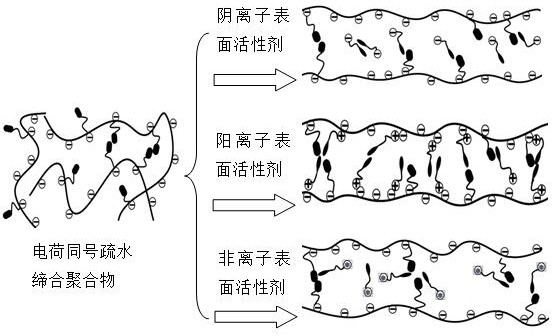

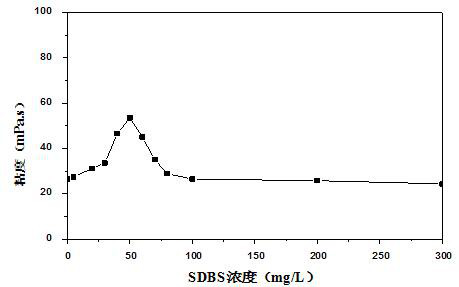

[0051] Example 1 Hydrophobically associating polymers interact with surfactants.

[0052] Preparation of hydrophobic association polymer mother liquor: first weigh the measured 5000mg / L NaCl brine in a stirred container, start the agitator, and slowly add a certain amount of the aforementioned hydrophobically modified polyacrylamide HP-Y dry powder purified to In the water, the dry powder should be added along the vortex. Pay attention to make the dry powder fully dispersed in the water, otherwise it is easy to form fish eyes. Stir at a constant speed (400r / min) in a constant temperature water bath at 45°C for 6 hours to prepare a polymer mother liquor with a mass concentration of 5000mg / L, and place it for 24 hours before use.

[0053] Preparation of surfactant mother liquor: Weigh a certain mass of anionic surfactant sodium dodecylbenzenesulfonate (SDBS), cationic surfactant octadecyltrimethylammonium chloride (1831), zwitterionic surfactant Agent octadecyl hydroxypropyl su...

Embodiment 2

[0065] Example 2 Competitive adsorption experiment of hydrophobic association polymer and surfactant.

[0066] According to the experimental results in Example 1, surfactant 1831 was selected as a representative for competitive adsorption experiments. The concentration of the surfactant was 300 mg / L, and the concentration of the hydrophobic association polymer HP-Y was 1200 mg / L.

[0067] Static adsorption capacity determination:

[0068] (1) Prepare a series of HP-Y and 1831 solutions with different mass concentrations in 5000mg / L NaCl brine, measure the concentration of HP-Y and 1831 in each solution in turn, which is the initial concentration before the oil displacement agent is adsorbed, denoted as C 0 ;

[0069] (2) Add quartz sand and oil-displacing agent to a solid-to-liquid ratio of 1:5 (10g quartz sand: 50mL oil-displacing agent) into a ground-mouthed Erlenmeyer flask with a stopper, shake and mix well, cover the bottle stopper, and use The sealing tape further sea...

Embodiment 3

[0093] Example 3 The effect of injection mode on the interaction between hydrophobically associating polymers and surfactants.

[0094] In this example, three different injection methods are used to inject HP-Y and 1831 components of the same quality, and the effects of these three injection methods on the hydrophobicity of porous media are investigated: Influence law of associative polymer-surfactant interaction.

[0095] Experimental steps of injection into flat sand-included mold with three pressure measuring points:

[0096] (1) Select 160-180 mesh quartz sand to fill the flat plate sand inclusion model, connect and debug the instrument, and put each working fluid into a high-precision injection pump for use;

[0097] (2) Saturate the filled flat plate sand model with 5000mg / L NaCl brine, measure its wet weight after 2 hours of saturation, and determine the pore volume (PV) and porosity of the model;

[0098] (3) Inject 4PV 5000mg / L NaCl brine, and measure the water perm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com