Method for promoting chalcopyrite bio-leaching based on iron-sulfur metabolism regulation

A technology of bioleaching and chalcopyrite, applied in the field of bioengineering, can solve the problems of unsuitability for large-scale popularization and application, poor effect, complicated operation means, etc., and achieves low equipment requirements, simple and easy operation, and promotes ion circulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Accumulation of bacterial body weight in the bioleaching process of acidophilus thermophilic Thiobacillus

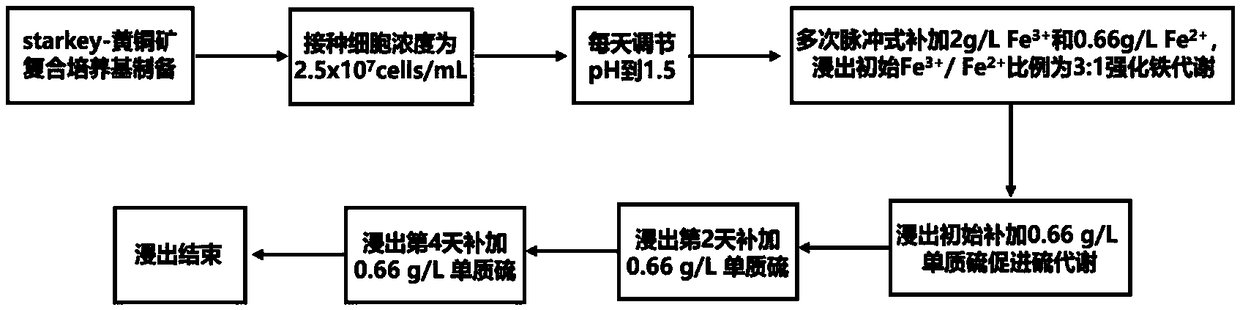

[0019] Starkey complex medium consists of three parts: the first part contains (NH 4 ) 2 SO 4 0.3g, KH 2 PO 4 3.0g, MgSO 4 ·7H 2 O 0.5g, CaCl 2 0.25g, Fe 2 (SO 4 ) 3 ·7H 2 O 0.018g, H 2 O 1000mL; second part: elemental sulfur 5g / L; third part 2% (w / v) lean chalcopyrite. The pH was adjusted to 1.5 after the first and second parts were mixed aseptically. The ore samples were taken from the Tonglingshan mining area in Anhui Province. After preliminary crushing and filtration with steel sieves, the ore particle size is about <48μm. The first part is sterilized at 121°C for 20 minutes by autoclaving. Then the three parts were mixed and shaken, and the pH of the solution was adjusted to 1.5 with 2 mol / L hydrochloric acid. The thermophilic Thiobacillus acidophilus was inoculated into the Starkey compound basal medium for cultivation, the culti...

Embodiment 2

[0020] Example 2 Optimization of Iron Metabolism in Chalcopyrite Leached by Thiobacillus Acidophilus

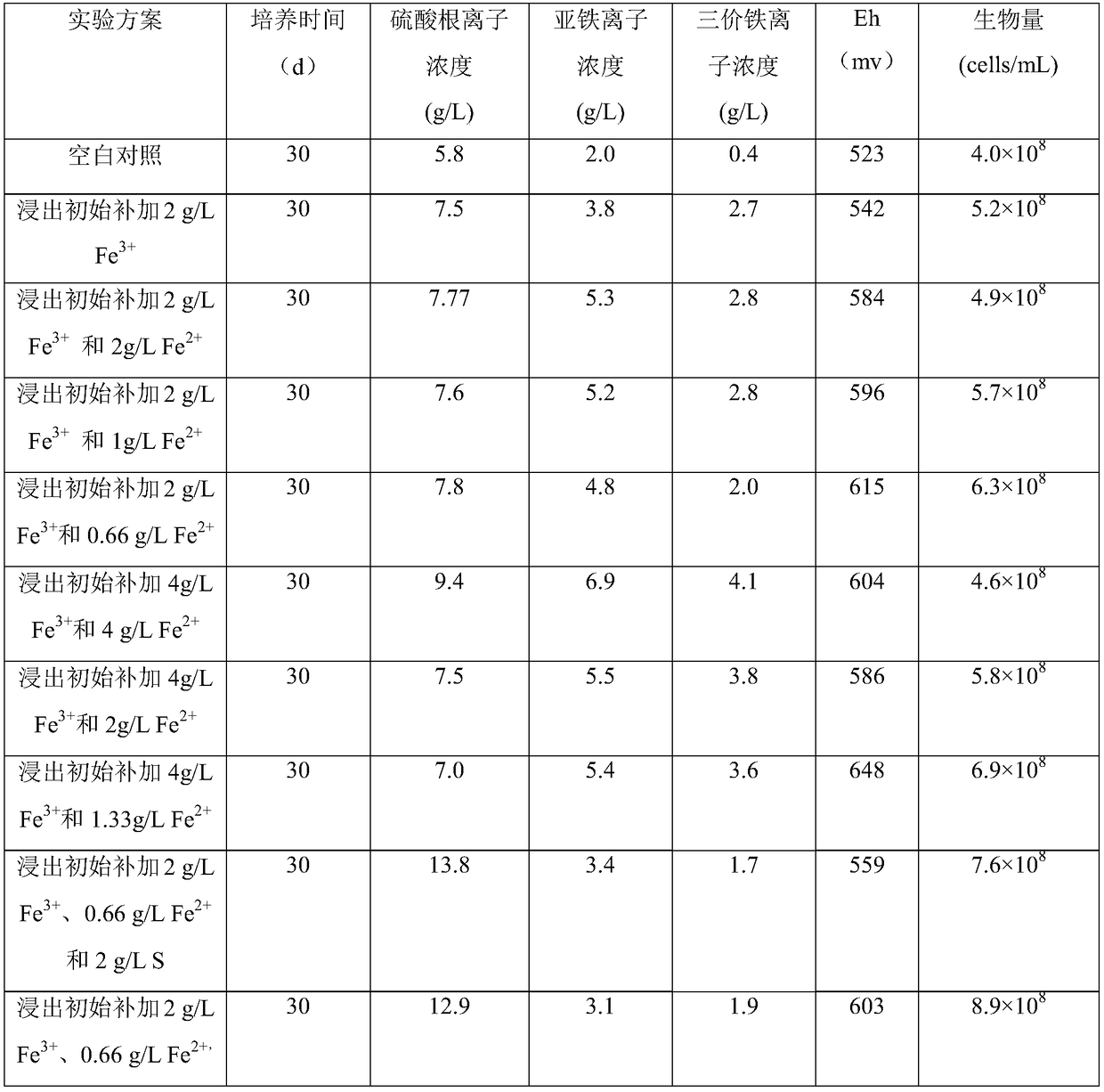

[0021] As shown in Table 1, by adding Fe at the initial stage of leaching 3+ (FeCl 3 Form), strengthen the oxidation of oxidant to chalcopyrite, so the copper ions in chalcopyrite in the initial stage of bioleaching can be released into the leach solution quickly. By adding Fe 2+ (FeSO 4 Form), control Fe 3+ and Fe 2+ At the initial ratio of leaching, the oxidation-reduction potential in the leaching solution is reduced, the reduction reaction is promoted, the iron metabolism in the leaching solution is accelerated, and the oxidation efficiency of sulfur is driven. The sulfate ion in Table 1 also proves that the additional addition of A system with a certain proportion of iron has a more active sulfur metabolism. and a certain amount of Fe 2+ Can catalyze the conversion of chalcopyrite into easily leached chalcocite (Cu 2 S). The final leaching rate of copper ions re...

Embodiment 3

[0026] Example 3 Optimization of Sulfur Metabolism in Leaching Depleted Chalcopyrite by Thiobacillus acidophilus

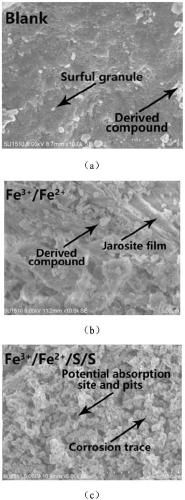

[0027] Scanning electron microscope (SEM) was used to observe the changes of slag surface morphology during the leaching process of chalcopyrite by Thiobacillus acidophilus under different leaching conditions. From figure 1 In a, it can be seen that the slag surface in the blank control without adding other substances during the leaching process is relatively smooth, and the corrosion marks are not obvious, but elemental sulfur and some other derivative particles appear, suggesting that the ion circulation on the chalcopyrite surface is not active. Add 2g / L Fe initially when leaching 3+ and 0.66g / L Fe 2+ when, from figure 1 In b, it can be seen that the dense passivation film in the system may be related to the imbalance of various biochemical reactions in the leaching environment, causing a large amount of elemental sulfur and jarosite to accumulate on the min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com