Alloy bonding wire for chip LED packaging and manufacturing method thereof

A technology of LED packaging and alloy bonding, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of unsatisfactory high temperature resistance, expensive bonding wires, and low qualification rate of devices, so as to improve bonding strength and Corrosion resistance, high qualified rate of finished products, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

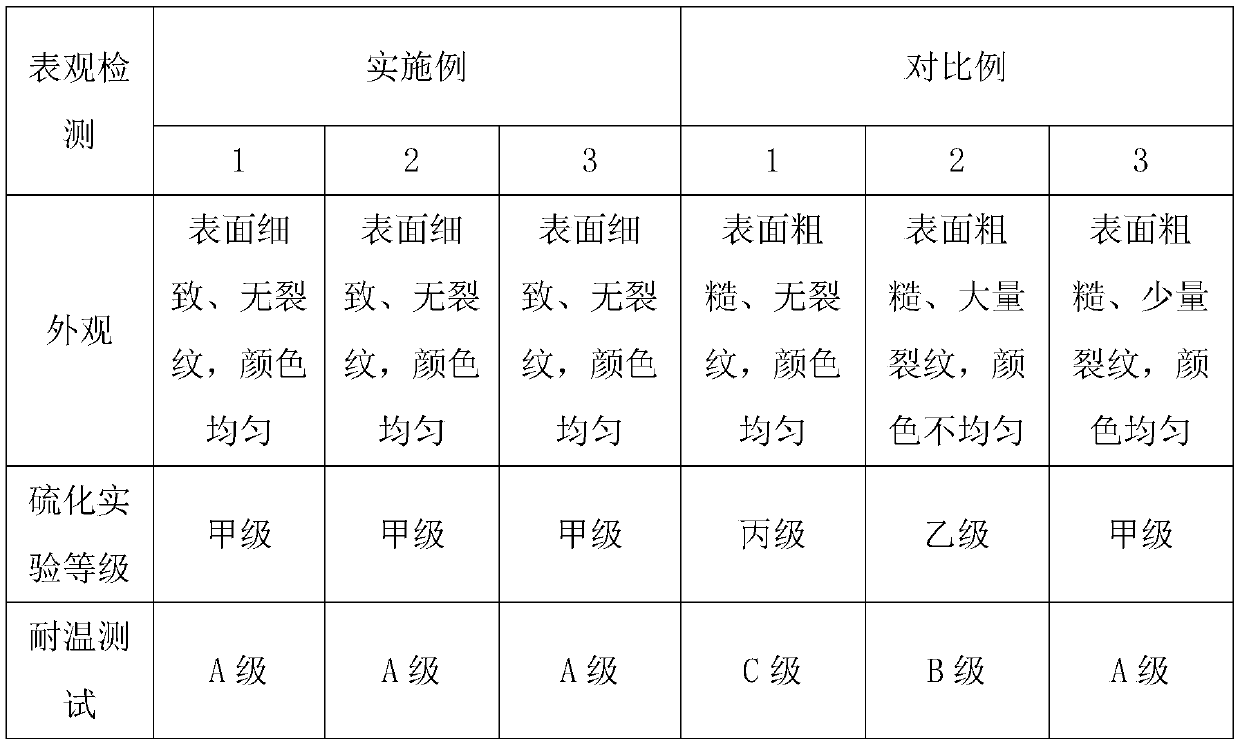

Embodiment 1

[0024] The alloy bonding wire for chip LED packaging proposed by the present invention uses a silver-based alloy as a matrix, and the silver-based alloy includes the following raw materials in parts by weight: 54 parts of silver, 1.4 parts of calcium, 0.3 part of samarium, 0.5 part of cerium; the surface of the substrate is coated with a protective layer, the protective layer is electroplated by a modified plating solution, and the thickness is 0.3 μm; the formula of the modified plating solution includes: palladium chloride 20g / L, 2,4-dichloroquinazoline 12g / L, 1-dodecyl imidazole 6ml / L, chitosan 2g / L, sodium dodecylbenzenesulfonate 40g / L, fumaric acid 23ml / L ;

[0025] The modified plating solution is prepared by the following method: adding chitosan to fumaric acid, ultrasonically dispersing at 40°C for 25 minutes, then adding 2,4-dichloroquinazoline and 1-dodecylimidazole, Stir at 55°C for 2 hours, then cool, add sodium dodecylbenzenesulfonate and palladium chloride in s...

Embodiment 2

[0035] The alloy bonding wire for chip LED packaging proposed by the present invention, the alloy bonding wire for chip LED packaging uses a silver-based alloy as a matrix, and the silver-based alloy includes the following raw materials in parts by weight: 60 parts of silver, 2.2 parts of calcium, 0.4 part of samarium and 0.7 part of cerium; the surface of the substrate is coated with a protective layer, and the protective layer is formed by electroplating with a modified plating solution with a thickness of 0.4 μm; the formula of the modified plating solution includes: palladium chloride 25g / L, 2,4-dichloroquinazoline 14g / L, 1-dodecyl imidazole 7ml / L, chitosan 3g / L, sodium dodecylbenzenesulfonate 50g / L, fumaric acid 26ml / L ;

[0036] The modified plating solution is prepared by the following method: adding chitosan to fumaric acid, ultrasonically dispersing at 45° C. for 20 minutes, then adding 2,4-dichloroquinazoline and 1-dodecylimidazole, Stir at 60°C for 1.5h, then cool...

Embodiment 3

[0046] The alloy bonding wire for chip LED packaging proposed by the present invention, the alloy bonding wire for chip LED packaging uses a silver-based alloy as a matrix, and the silver-based alloy includes the following raw materials in parts by weight: 65 parts of silver, 2.8 parts of calcium, 0.6 part of samarium, 0.8 part of cerium; the surface of the substrate is coated with a protective layer, and the protective layer is formed by electroplating with a modified plating solution with a thickness of 0.5 μm; the formula of the modified plating solution includes: palladium chloride 30g / L, 2,4-dichloroquinazoline 16g / L, 1-dodecyl imidazole 8ml / L, chitosan 4g / L, sodium dodecylbenzenesulfonate 60g / L, fumaric acid 28ml / L ;

[0047] The modified plating solution is prepared by the following method: adding chitosan to fumaric acid, ultrasonically dispersing at 50° C. for 15 minutes, then adding 2,4-dichloroquinazoline and 1-dodecylimidazole, Stir at 65°C for 1 hour, then cool,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com