Yarn for cell culture support, ply twisted yarn containing same, and fabric containing same

A technology of cell culture and yarn, applied in cell culture support/coating, fabric, tissue culture, etc., can solve problems such as no effect, limited growth, proliferation, migration, differentiation, etc., to improve value-added rate and survival rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

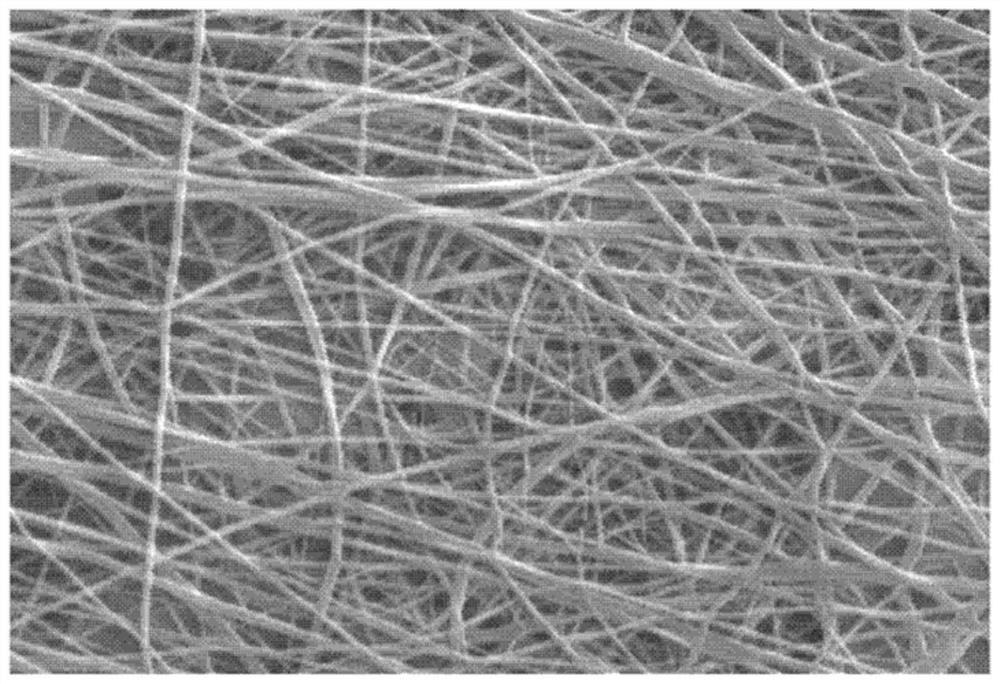

[0084]A spinning solution was prepared by dissolving polyvinylidene fluoride as a fiber forming component in DMAc / acetone (Acetone) as a mixed solution at 15% by weight. Utilize the electrospinning device to electrospin the above-prepared spinning solution, as the electrospinning conditions, the applied voltage is 25KV, the distance between the current collector and the spinning port is 25cm, the discharge volume is 0.05ml / hole, at RH65% Electrospinning was carried out under an environment of 30° C. to obtain a nanofiber web roll (Roll) with a width of 1.5 m, a weight of 5 g / ㎡, and a length of 500 m. Image 6 Part (a) is a photo of the prepared nanofibrous web by winding, Image 6 Part (b) is a photograph of a scanning electron microscope showing a nanofibrous web. Such as Image 6 As shown in part (b), the average diameter of the nanofibers forming the nanofiber web is about 230 nm.

Embodiment 2

[0085] Embodiment 2. Slitting yarn preparation and twisting

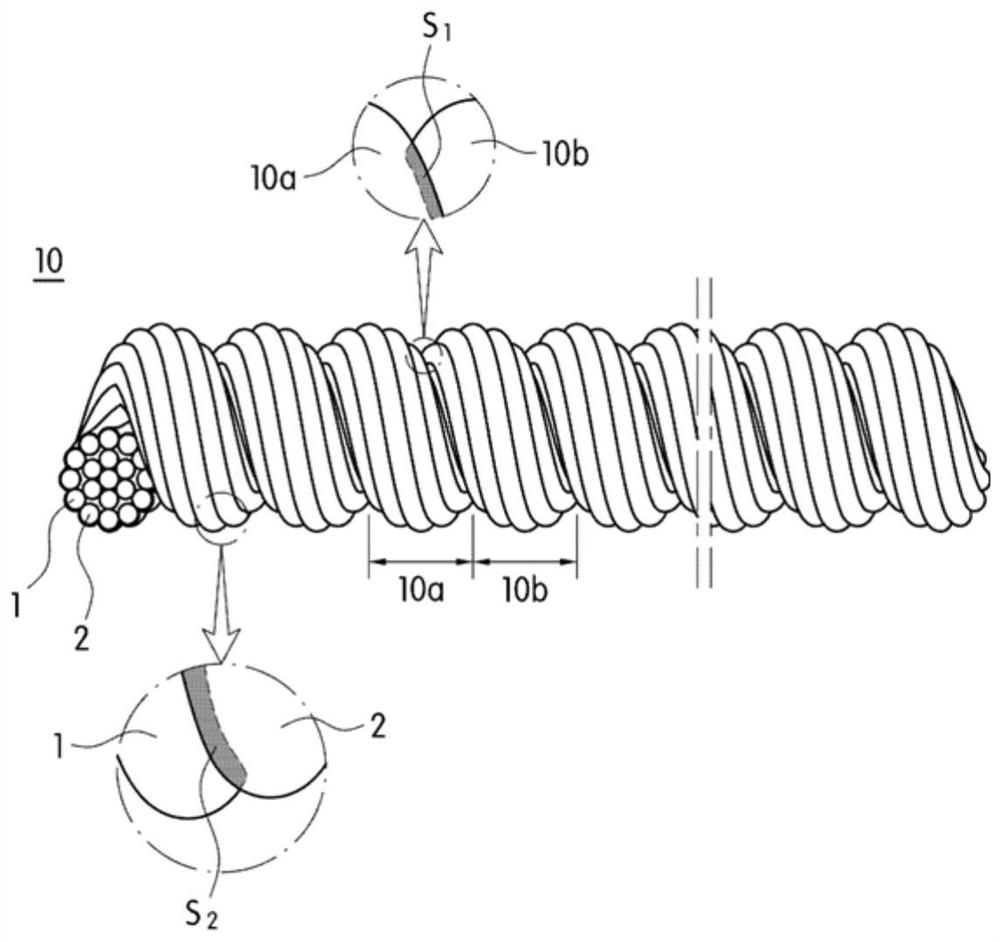

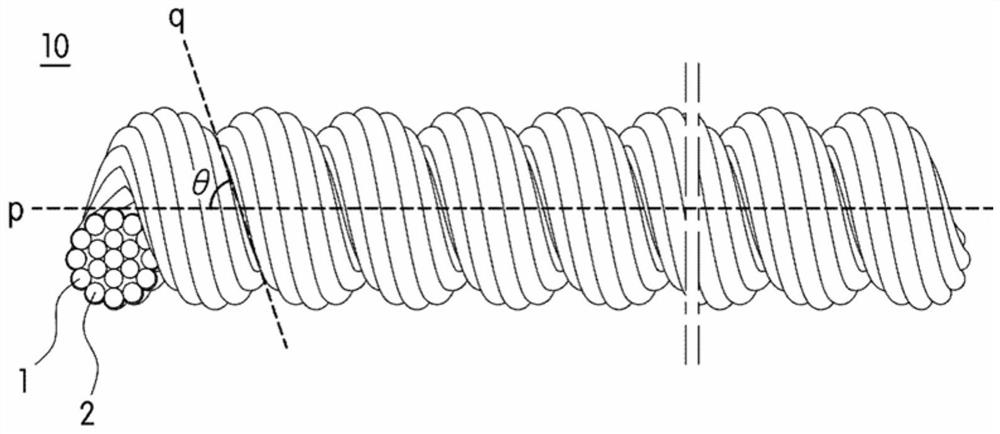

[0086] Such as Figure 7 Shown in part (a), after the roll of the nanofibrous web prepared in embodiment 1 is slitting for the first time with a width of 5mm, as Figure 7 As shown in part (b) of , the second precise slitting is carried out so that each width is 1.5mm to obtain the slitting yarn, and the winding photo of the slitting yarn prepared in the second precise slitting process is as follows Figure 7 as shown in part (c). Such as Figure 3a As shown, the width of the prepared slit yarn is 1.5mm. Using a 2-in-1 twister, the prepared slit yarn was Z-twisted so that the kink per minute was 700 T / M (T / M, twist / meter) to prepare a twisted yarn for cell scaffolds. Figure 8 Part (a) is a photograph showing the yarn wound with twisted yarn, Figure 8 Part (b) is a scanning electron micrograph of the surface of the twisted yarn, and it can be confirmed that two slit yarns are twisted to form multiple twists. ...

Embodiment 3~5

[0087] Embodiment 3~5. ply twisted yarn preparation

[0088] The slitting yarns prepared in Example 2 were plied with different yarns of nylon monofilament yarns of 20 deniers, polyester (Polyester) DTY of 30 deniers, and cotton of 60 counts respectively, and were plied by using a double twister to The condition of 1000T / M implements double twisting. Figure 9 A photograph and a scanning electron microscope photograph of the multi-twisted yarn prepared above are shown, respectively. Such as Figure 9 As shown, it can be confirmed that even in the case of preparing a plied twisted yarn of a slitting yarn and a different type of yarn, the plied twisted yarn is smoothly produced without fiber breakage, and it can be confirmed that a plurality of twists are formed by the plied twisted yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com