Solid cloud detonation explosive

An explosive, solid technology, applied in the direction of explosives, etc., can solve the problems of inability to further improve the power of cloud explosives, affecting the use and safe storage of ammunition, low fuel combustion efficiency, etc. power, and the effect of improving the utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Table 1 shows the performance comparison of fuel air explosive formulations MN-1 and MN-2 with different hydrocarbon fuels and primary detonation basic formulation 1.

[0043] Table 1 formula composition (weight %) and performance

[0044]

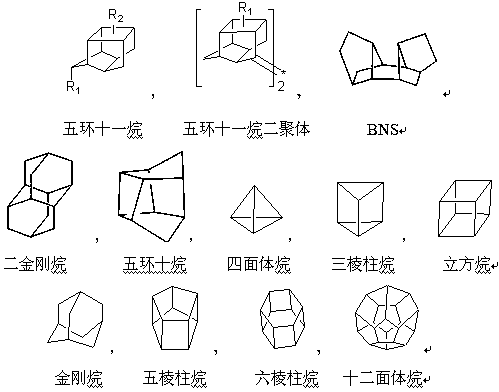

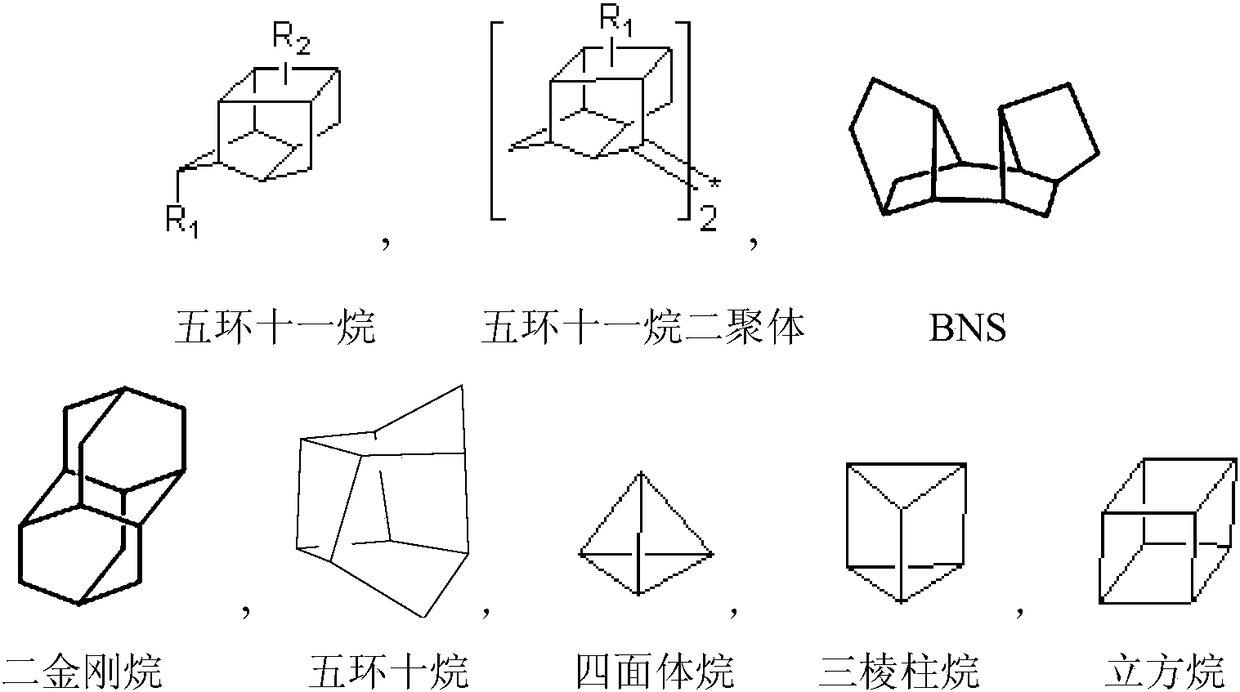

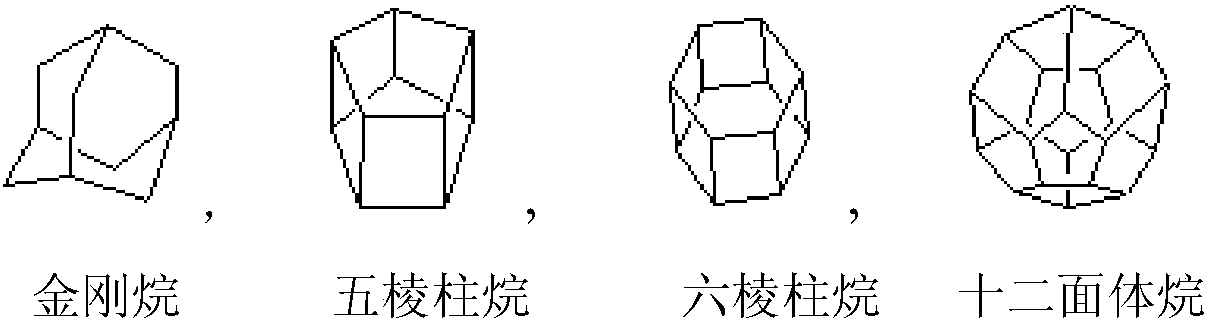

[0045]It can be seen from Table 1 that the density, heat of combustion, detonation volume and power of the fuel air explosive formulations MN-1 and MN-2 containing pentacyclodecane and diamantane are significantly higher than those of the basic formulation 1. Among them, the density of MN-2 formula has been increased by 3%, the heat of combustion has been increased by 25%, the heat of combustion by volume has been increased by 29%, and the power has been increased by 23%. The detonation capacity has been increased by 43%, and the volume of gas formed by unit mass explosive is 1.43 times that of the basic formula, which can significantly expand the coverage area of the detonation cloud area and enhance the lethality of the fuel....

Embodiment 2

[0047] Table 2 shows the performance comparison of fuel air explosive formulations MN-3 and MN-4 with different hydrocarbon fuels and primary detonation basic formulation 2.

[0048] Table 2 formula composition (weight %) and performance

[0049]

[0050] As can be seen from Table 2, the density, heat of combustion and power of the fuel air explosive formulations MN-3 and MN-4 containing pentacyclodecane and cubane are all higher than those of the basic formulation 2. For hydrocarbon fuels, compared with the polymer binder HTPB, the energetic particles in fuel air explosives are easier to be ignited, so the energy release efficiency is higher.

Embodiment 3

[0052] Table 3 shows the performance comparison of fuel air explosive formulations MN-5 and MN-6 with different hydrocarbon fuels and primary detonation basic formulation 3.

[0053] Table 3 formula composition (weight %) and performance

[0054]

[0055]

[0056] It can be seen from Table 3 that the density, heat of combustion, detonation capacity and power of the fuel air explosive formulations MN-5 and MN-6 containing pentacycloundecane and diamantane are significantly higher than those of the basic formulation 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com