Organic hole transport material taking tetrathienopyrrole as core as well as preparation method and application thereof

A hole transport material, phenopyrrole technology, applied in the field of solar cells, can solve the problems of low efficiency, complex synthesis, poor stability, etc., achieve good dissolution and film-forming performance, simple synthesis route, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Synthesis of Organic Hole Transport Material (4)

[0028] The synthetic route is as follows:

[0029]

[0030] The raw material (1) used in this example was prepared and synthesized according to the patent (authorization number: ZL 201610828658.0); the raw material (3) was prepared according to the literature Rakstys, K.; Abate, A.; Ibrahim Dar, M.; Gao, P.; Jankauskas, V.; Jacopin, G.; Kamarauskas, E.; Kazim, S.; Ahmad, S.; M.; Nazeeruddi, M.K.J.Am.Chem.Soc.2015, 137, 16172-16178. Prepared; other reagents can be obtained commercially.

[0031] The synthesis of formula (2) compound:

[0032] Add 636mg of raw material (1) and 20mL of tetrahydrofuran to a 100mL single-necked round-bottomed flask under ice-bath conditions, then add 392mg of N-bromosuccinimide in batches to the system, at 25°C, in the dark Reaction for 8 hours; quenched with water, extracted with ethyl acetate, dried over anhydrous magnesium sulfate, and evaporated under reduced pressure to remove th...

Embodiment 2

[0036] The synthesis of formula (2) compound:

[0037] Add 636mg of raw material (1) and 20mL of N,N-dimethylformamide to a 100mL single-necked round-bottom flask under ice-bath conditions, and then add 374mg of N-bromosuccinimide in batches to the system , at 25°C, reacted in the dark for 8h; quenched with water, extracted with ethyl acetate, dried over anhydrous magnesium sulfate, and distilled off the solvent under reduced pressure; the crude product was subjected to column chromatography (eluent: petroleum ether / dichloromethane = 25 / 1~15 / 1) to obtain 650 mg of the compound represented by formula (2) as a white solid with a yield of 82%.

[0038] Synthesis of Organic Hole Transport Material (4):

[0039] Under the protection of argon, in a 100mL three-necked round-bottomed flask, 397mg of the compound shown in formula (2), 495mg of the compound shown in formula (3), 29mg of tetrakistriphenylphosphine palladium, 690mg of potassium phosphate (2M) and 15mL of N,N-dimethylfor...

Embodiment 3

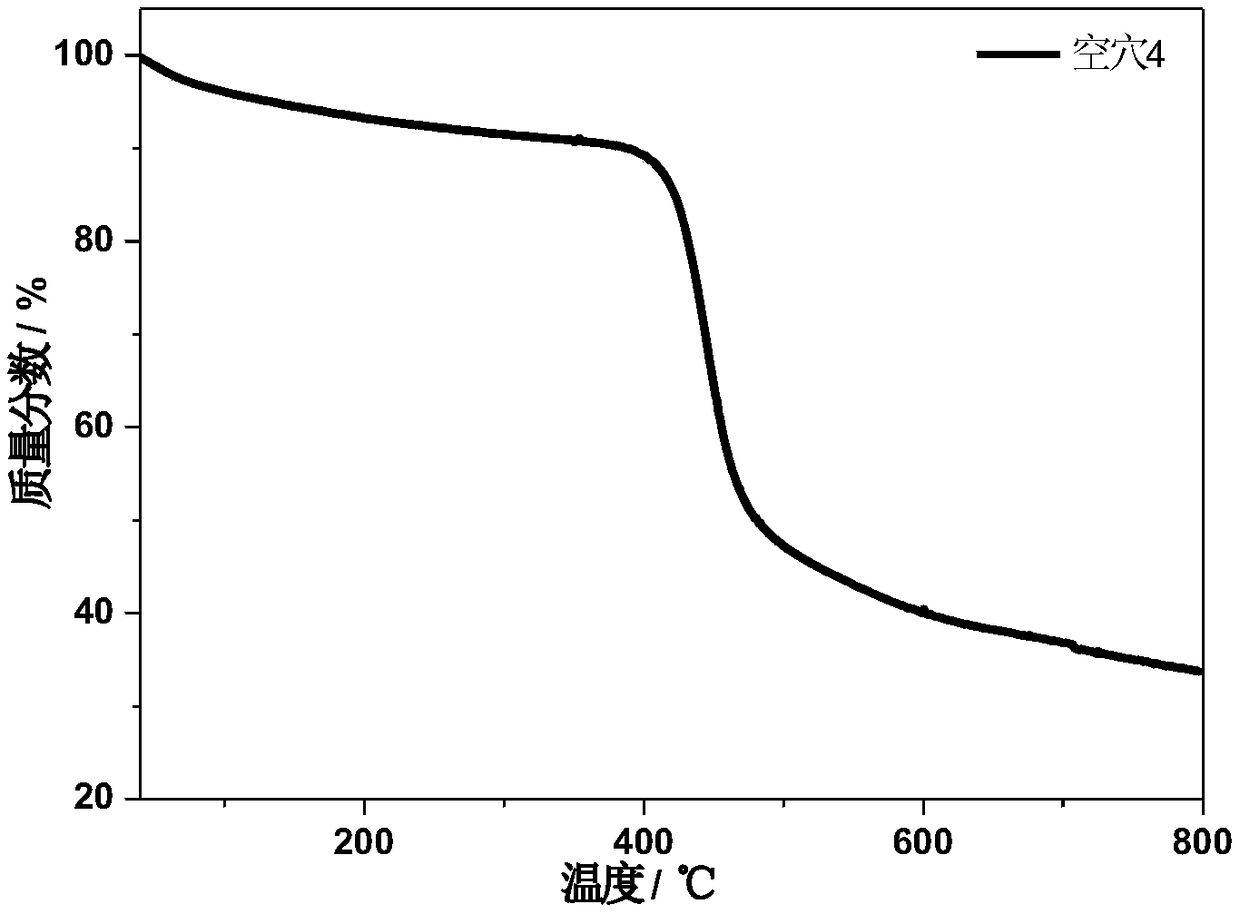

[0041] The organic hole transport (4) prepared in Example 1 or 2 was tested by thermogravimetric analysis (TGA). The test temperature range was 0-800°C, and the heating rate was 5°C / min. The test results (see figure 1 ) shows that its thermal decomposition temperature is 390°C, indicating that it has good thermal stability.

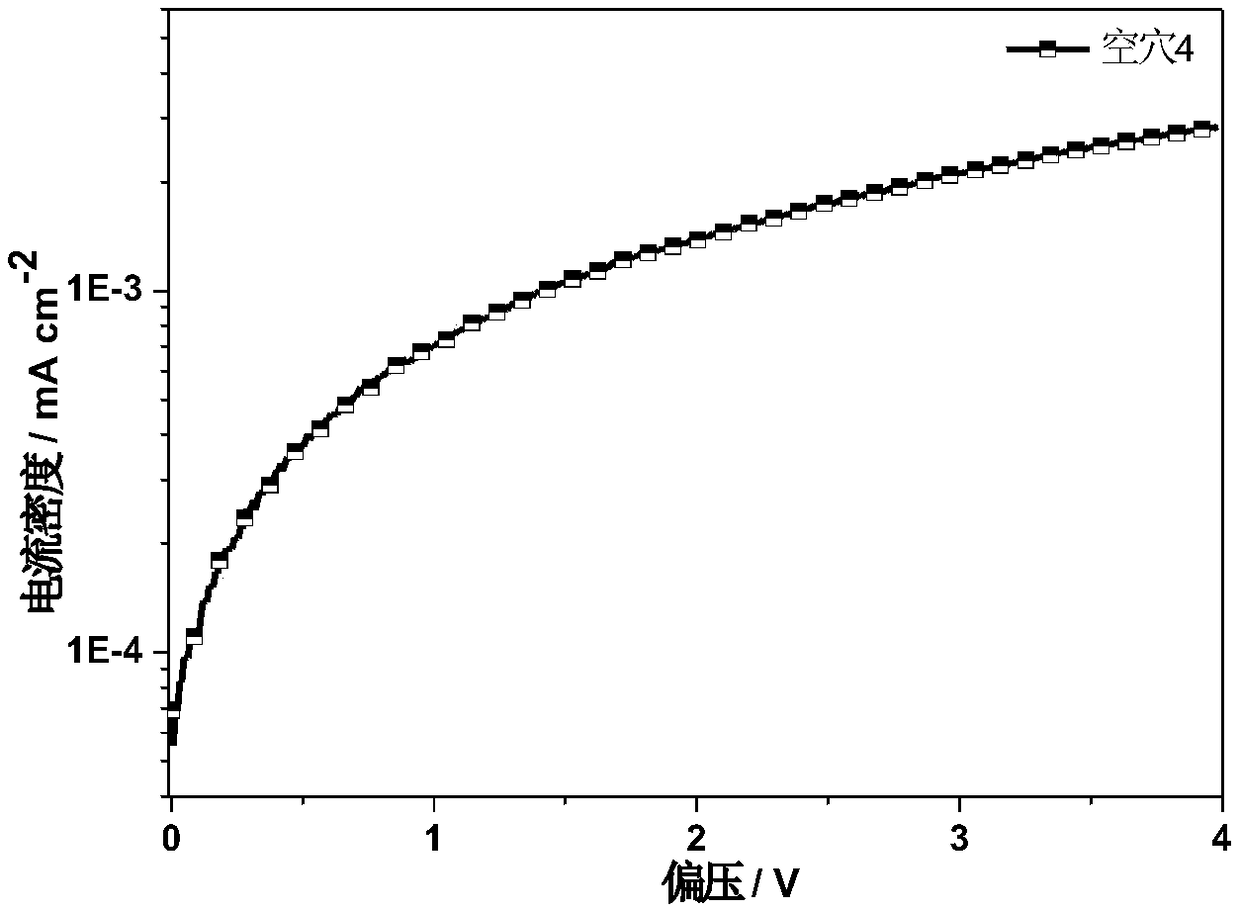

[0042] The hole transfer efficiency of organic holes (4) was tested by space charge limited current (SCLC) method. The relationship between hole transfer efficiency, current density and bias voltage is as follows: μ=8d 3 J / 9ε 0 ε r V 2 , where d is the hole film thickness (cm), J is the current density (mA / cm 2 ),ε 0is the vacuum dielectric constant (8.85×10 -14 C V -1 cm -1 ),ε r is a constant 3, and V is the setting bias voltage (V). The hole transfer efficiency of organic holes (4) calculated according to the test and formula is 2.18×10 - 4 cm 2 V -1 S -1 .

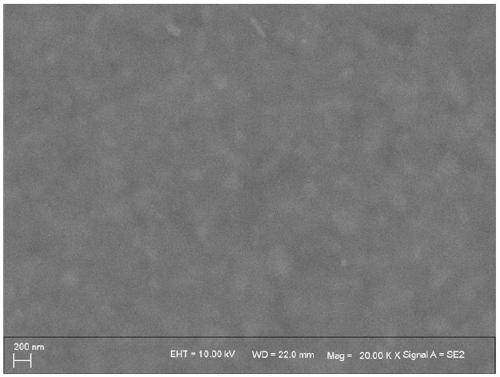

[0043] The organic hole transport (4) prepared in embodiment 1 or 2, its scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com