A preparation method of a nickel-rich ternary material coated with cobalt lithium phosphate

A ternary material, lithium cobalt phosphate technology, applied in the direction of phosphate, phosphorus oxyacid, chemical instruments and methods, etc., can solve the problems of material performance degradation, high cost, uniformity can not be guaranteed, etc., to achieve pH value and residual Effects of reduced lithium content, improved cycle performance, and improved processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

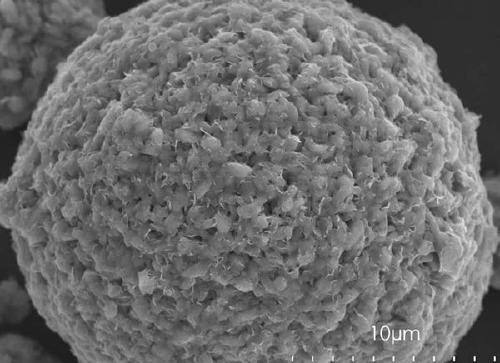

Embodiment 1

[0032] The nickel-rich ternary material used is LiNi in the prior art 0.6 co 0.2 mn 0.2 o 2 powder (referred to as NCM622 powder).

[0033] 1. A method for preparing a nickel-rich ternary material coated with lithium cobalt phosphate, comprising the following steps:

[0034] (1) Cobalt hydroxide coated on the surface of nickel-rich ternary material:

[0035] (1a) Cobalt sulfate (CoSO 4 ·7H 2 O) Dissolved in pure water to prepare 0.62L of cobalt sulfate salt solution of 0.1mol / L;

[0036] (1b) Add sodium hydroxide and ammonia water to pure water to prepare 0.62L of mixed alkali solution with concentrations of 0.2mol / L and 0.01mol / L respectively;

[0037] (1c) In a nitrogen atmosphere, 2000 g of LiNi 0.6 co 0.2 mn 0.2 o 2 Add 5L of pure water into the reaction kettle and stir evenly, then add the cobalt sulfate salt solution and mixed alkali solution prepared in steps (1a) and (1b), control the temperature of the reaction kettle to 50°C, pH=10.8, and obtain cobalt hyd...

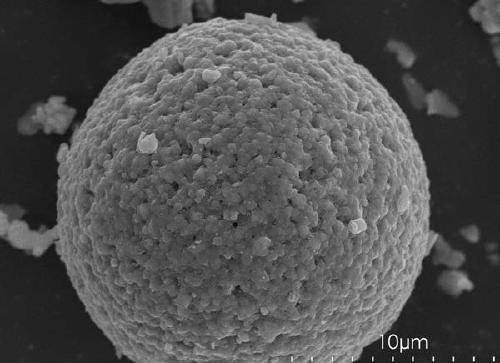

Embodiment 2

[0042] The nickel-rich ternary material used is LiNi in the prior art 0.6 co 0.2 mn 0.2 o 2 powder.

[0043] 1. A method for preparing a nickel-rich ternary material coated with lithium cobalt phosphate, comprising the following steps:

[0044] (1) Cobalt hydroxide coated on the surface of nickel-rich ternary material:

[0045] (1a) Cobalt sulfate (CoSO 4 ·7H 2 O) Dissolved in pure water to prepare 0.62L of cobalt sulfate salt solution of 0.05mol / L;

[0046] (1b) Add sodium hydroxide and ammonia water to pure water to prepare 0.62L of mixed alkali solution with concentrations of 0.1mol / L and 0.05mol / L respectively;

[0047] (1c) In a nitrogen atmosphere, 2000 g of LiNi 0.6 co 0.2 mn0.2 o 2 (abbreviated as NCM622 powder) and 5L of pure water were added to the reactor and stirred evenly, then the cobalt sulfate salt solution and mixed alkali solution prepared in steps (1a) and (1b) were added, and the temperature of the reactor was controlled at 40°C and pH=12 to obta...

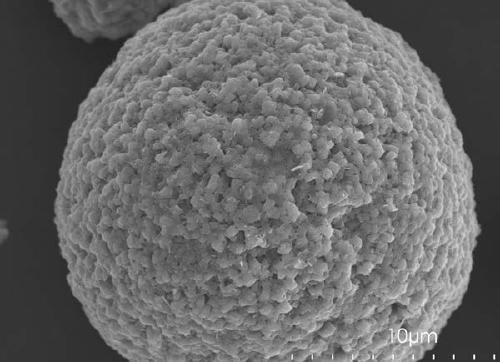

Embodiment 3

[0052] The nickel-rich ternary material used is LiNi in the prior art 0.6 co 0.2 mn 0.2 o 2 powder.

[0053] 1. A method for preparing a nickel-rich ternary material coated with lithium cobalt phosphate, comprising the following steps:

[0054] (1) Cobalt hydroxide coated on the surface of nickel-rich ternary material:

[0055] (1a) Cobalt sulfate (CoSO 4 ·7H 2 O) Dissolved in pure water to prepare 0.62L of cobalt sulfate salt solution of 0.5mol / L;

[0056] (1b) Add sodium hydroxide and ammonia water to pure water to prepare 0.62L of mixed alkali solution with concentrations of 1mol / L and 0.005mol / L respectively;

[0057] (1c) In a nitrogen atmosphere, 2000 g of LiNi 0.6 co 0.2 mn 0.2 o 2 (abbreviated as NCM622 powder) and 5L of pure water were added to the reactor and stirred evenly, then the cobalt sulfate salt solution and mixed alkali solution prepared in steps (1a) and (1b) were added, and the temperature of the reactor was controlled at 60°C and pH=9 to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com