Preparation method for niobium alloy thin walled tube of corrugated pipe

A technology of niobium alloy and thin-walled pipes, which is applied in the field of preparation of refractory material pipes, can solve problems such as corrugated pipes that cannot be satisfied, and achieve the effects of suitable promotion and application, short production process, and expanded use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the present embodiment comprises the following steps:

[0024] Step 1. Cut the fully recrystallized niobium alloy pipe to length to 40 mm, then polish the nozzle of the cut niobium alloy pipe smoothly, and clean the inner and outer surfaces; the completely recrystallized niobium alloy pipe The outer diameter is 35.8mm±0.05mm, the wall thickness is 1.0mm±0.08mm, and the surface roughness Ra≤1.6μm; the fully recrystallized niobium alloy pipe refers to the niobium alloy pipe that has been annealed to a completely recrystallized state after rolling. Seamed niobium alloy pipe, the composition of the seamless niobium alloy pipe is Nb-5W-2Mo-1Zr;

[0025] Step 2: Put balls with a diameter of 5 mm into the mold of the ball spinning equipment and apply 20 # machine oil, and then the ball spinning equipment is debugged; in the debugging process, the longitudinal feed speed of the ball spinning equipment is 10mm / min, and the spindle speed is 800 revoluti...

Embodiment 2

[0029] The preparation method of the present embodiment comprises the following steps:

[0030] Step 1. Cut the fully recrystallized niobium alloy pipe to length to 75 mm, then polish the nozzle of the cut niobium alloy pipe smoothly, and clean the inner and outer surfaces; the completely recrystallized niobium alloy pipe The outer diameter is 12.8mm±0.05mm, the wall thickness is 0.44mm±0.02mm, and the surface roughness Ra≤1.6μm; the fully recrystallized niobium alloy pipe refers to the niobium alloy pipe that has been annealed to a completely recrystallized state after rolling. Seamed niobium alloy pipe, the composition of the seamless niobium alloy pipe is Nb-5W-2Mo-1Zr;

[0031] Step 2: Put balls with a diameter of 3.5 mm into the mold of the ball spinning equipment and apply 20 # machine oil, and then the ball spinning equipment is debugged; in the debugging process, the longitudinal feed speed of the ball spinning equipment is 17mm / min, and the spindle speed is 950 revol...

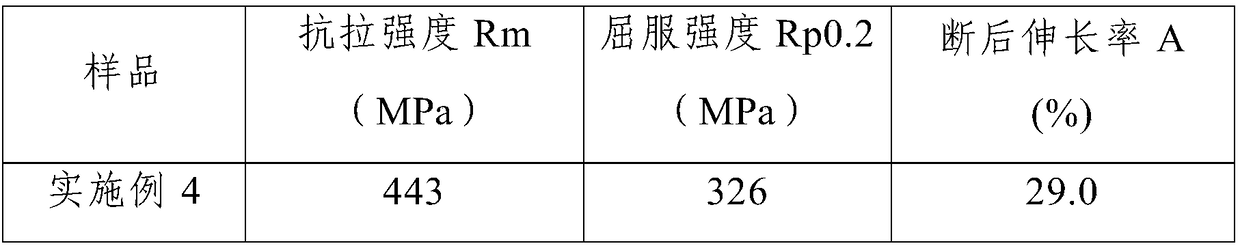

Embodiment 3

[0036] The preparation method of the present embodiment comprises the following steps:

[0037] Step 1. Cutting the fully recrystallized niobium alloy pipe to a length of 70 mm, then grinding the nozzle of the cut niobium alloy pipe smoothly, and cleaning the inner and outer surfaces; the completely recrystallized niobium alloy pipe is The outer diameter is 21mm±0.05mm, the wall thickness is 0.56mm±0.03mm, and the surface roughness Ra≤1.6μm; the fully recrystallized niobium alloy pipe refers to the seamless tube that has been annealed to a completely recrystallized state after rolling. Niobium alloy pipe, the composition of the seamless niobium alloy pipe is Nb-5W-2Mo-1Zr;

[0038] Step 2: Put a ball with a diameter of 3mm into the mold of the ball spinning equipment and apply 20% to the surface of the core rod of the ball spinning equipment # machine oil, and then the ball spinning equipment is debugged; in the debugging process, the longitudinal feed speed of the ball spinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com