Integrated treatment process of active printing and dyeing waste water

A technology of printing and dyeing wastewater and treatment process, which is applied in textile industry wastewater treatment, multi-stage water treatment, anaerobic digestion treatment, etc., can solve the problem of low energy consumption, achieve small dispersion, good stability, and enhance complexation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The integrated treatment process I of embodiment 1 reactive printing and dyeing wastewater

[0032] Step 1. Physicochemical pretreatment: Filter the printing and dyeing wastewater through the grid to remove the suspended solids and floating solids with large particles, then pump it into the adjustment tank and adjust its pH;

[0033] Step 2, biochemical treatment: the effluent treated in step 1 passes through aerobic aeration tank and anaerobic bioreactor to reduce chemical oxygen demand, biochemical oxygen demand and ammonia oxygen concentration;

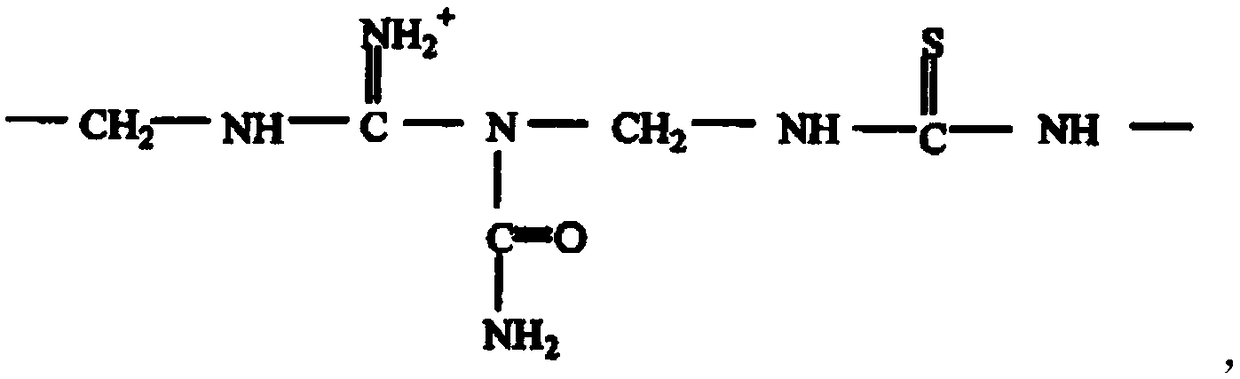

[0034] Step 3, flocculation and sedimentation treatment: pump the effluent treated in step 2 into the physical and chemical sedimentation tank, and add composite flocculant I to further remove suspended solids, colloidal substances, organic matter and decolorization in wastewater; composite flocculant I is determined by molar ratio It is compounded by (2-5): (5-8) anionic polyelectrolyte and water-soluble cationic flocculant...

Embodiment 2

[0041] The integrated treatment process II of embodiment 2 active printing and dyeing wastewater

[0042] Step 1. Physicochemical pretreatment: Filter the printing and dyeing wastewater through the grid to remove the suspended solids and floating solids with large particles, then pump it into the adjustment tank and adjust its pH;

[0043] Step 2, biochemical treatment: the effluent treated in step 1 passes through aerobic aeration tank and anaerobic bioreactor to reduce chemical oxygen demand, biochemical oxygen demand and ammonia oxygen concentration;

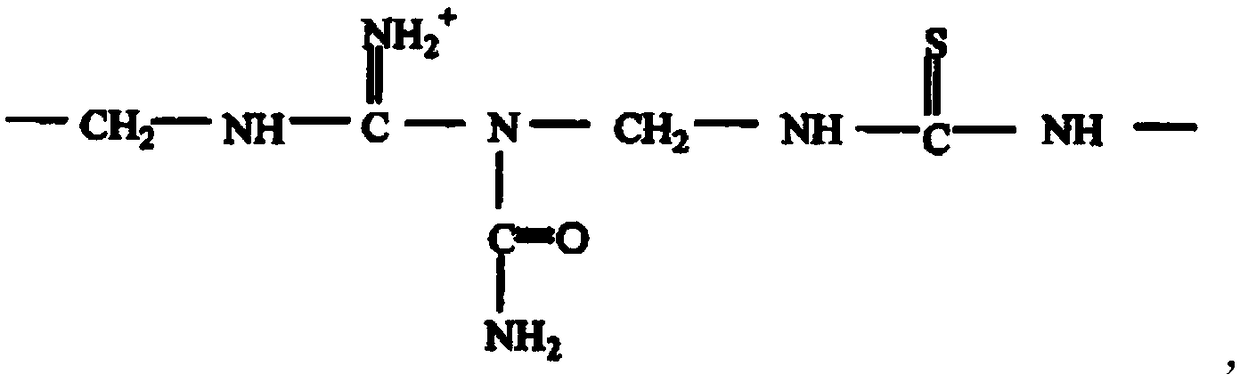

[0044] Step 3, flocculation and sedimentation treatment: pump the effluent treated in step 2 into the physical and chemical sedimentation tank, and add composite flocculant II to further remove suspended solids, colloidal substances, organic matter and decolorization in wastewater; composite flocculant II is determined by molar ratio It is compounded by (2-5): (5-8) anionic polyelectrolyte and water-soluble cationic flocculan...

Embodiment 3

[0051] The integrated treatment process III of embodiment 3 active printing and dyeing wastewater

[0052] Step 1. Physicochemical pretreatment: Filter the printing and dyeing wastewater through the grid to remove the suspended solids and floating solids with large particles, then pump it into the adjustment tank and adjust its pH;

[0053] Step 2, biochemical treatment: the effluent treated in step 1 passes through aerobic aeration tank and anaerobic bioreactor to reduce chemical oxygen demand, biochemical oxygen demand and ammonia oxygen concentration;

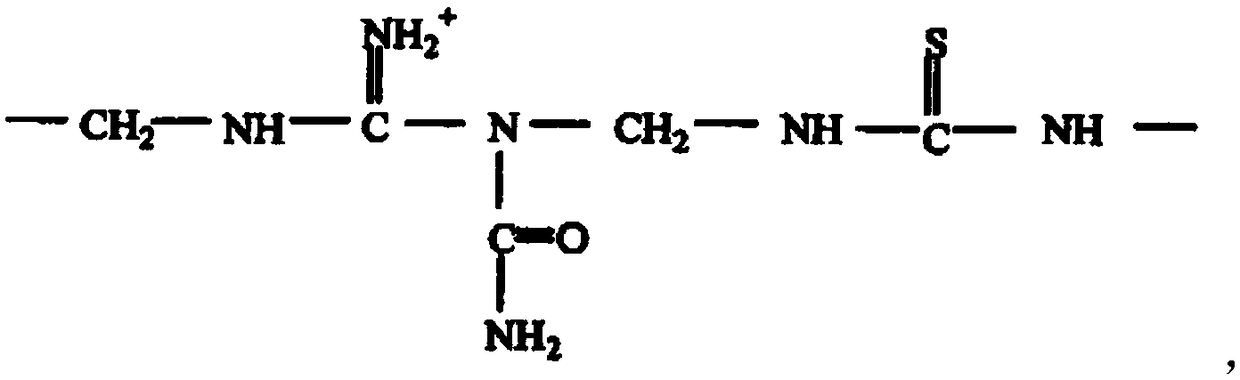

[0054] Step 3, flocculation and sedimentation treatment: pump the effluent treated in step 2 into the physical and chemical sedimentation tank, and add composite flocculant III to further remove suspended solids, colloidal substances, organic matter and decolorization in wastewater; composite flocculant III is determined by molar ratio It is compounded by (2-5): (5-8) anionic polyelectrolyte and water-soluble cationic floccu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com