Polyester-amino baking enamel for roll aluminum

A technology of polyester amino baking varnish and polyester resin, applied in the field of coatings, can solve problems such as health hazards, environmental pollution, aggravated photochemical smog pollution, regional haze and atmospheric compound pollution, etc., achieve high decorativeness, improve flexibility, and excellent The effect of antibacterial treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

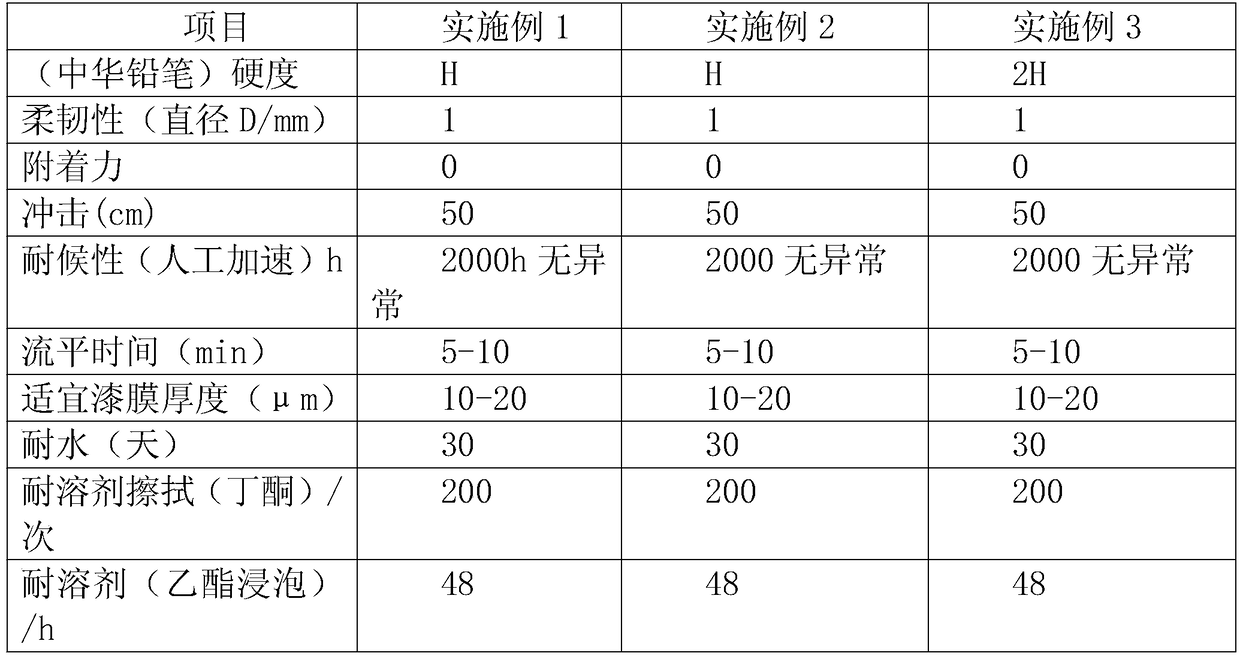

[0024] Each specific embodiment 1-3 is shown in the following table:

[0025] Raw material (kg)

Example 1

Example 2

Example 3

30-45 parts saturated polyester resin

30

35

40

4-10 parts of hexamethoxymethylmelamine resin

4

6

8

3-5 parts of co-solvent

3

4

5

1-3 parts of pH adjuster

2

2.5

3

2-4 parts of blocked water-based isocyanate

2

3

4

0.5-1 part of defoamer

0.5

0.6

0.8

0.5-1.5 parts of dispersant

1

1.2

1.5

0.3-0.5 parts of substrate wetting agent

0.3

0.4

0.5

20-30 parts deionized water

30

25

25

0.2-0.4 leveling agent

0.3

0.4

0.4

3-30 parts of pigment

30

10

5

[0026] Wherein: the polyester resin is DSM SZ260 saturated polyester resin; the hexamethoxymethylmelamine resin is 303 amino resin of CYTEC; ; The blocked water-based isocyanate is Bayer BL5140; the pH regulator is the dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com