Preparation method for medical ozonized oil

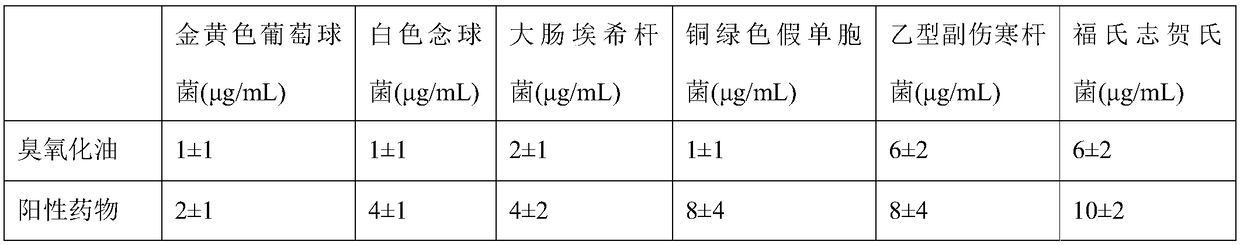

A technology of ozonated oil and ozonation, which is applied in the fields of drug synthesis and organic synthesis, can solve the problems of inaccurate detection of active components of ozonated oil, poor stability of peroxides, easy escape of gas components, etc., and achieve low manufacturing cost , high antibacterial activity, ensure the effect of judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

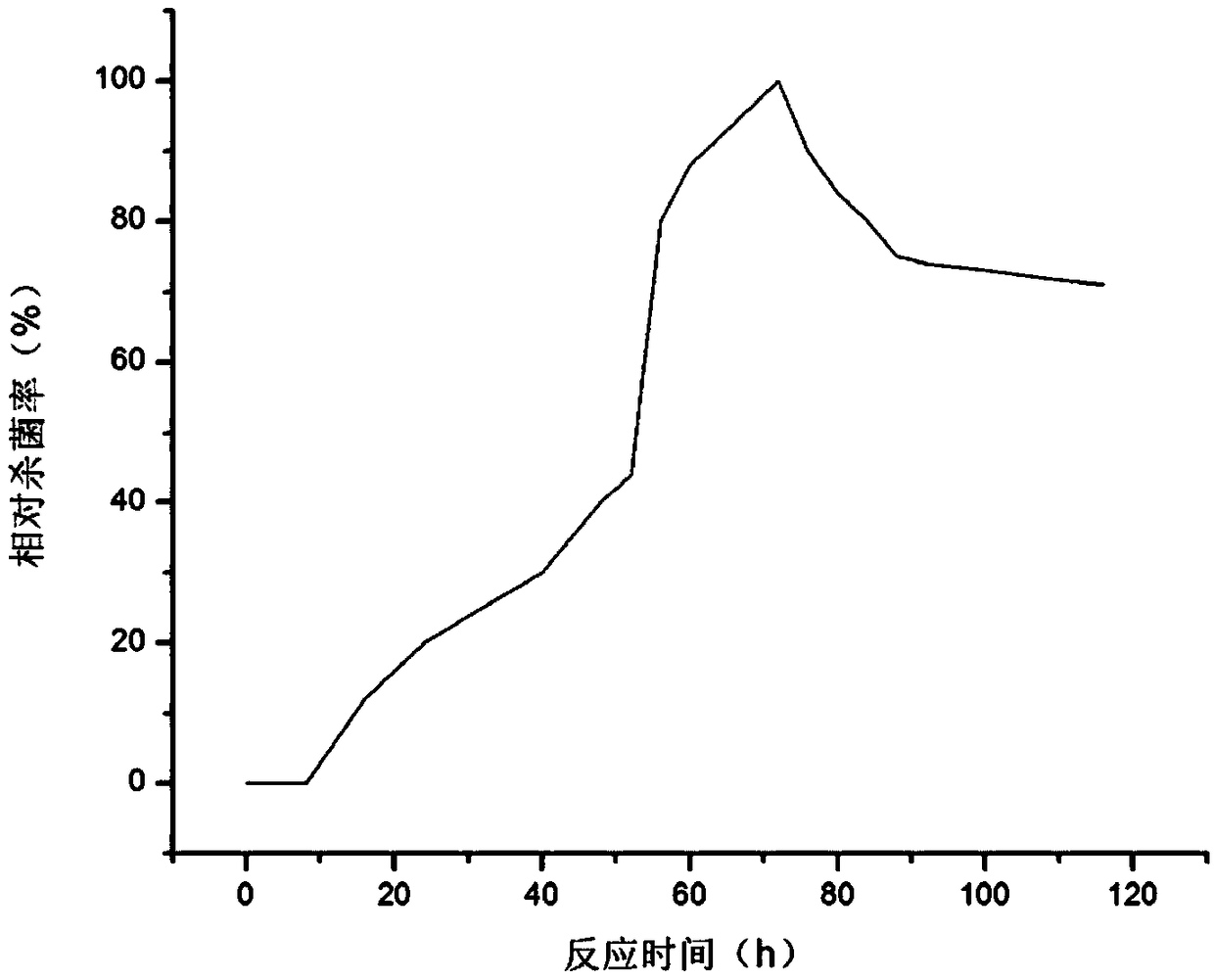

[0030] Add 50mL of olive oil to a 100mL three-necked flask equipped with a stirring (magnetic force) and temperature control device, set the reaction temperature to 5°C, and after the reaction system reaches the set temperature and stabilizes, turn on the air source type ozone generator and set The fixed power is 100W, the ozone output is 10g / h, and the ozone content is 150ppm (the other components introduced are nitrogen, oxygen and a small amount of carbon dioxide in the air). Below the surface, above the stirring magnet. During the process of feeding ozone into the olive oil, the stirring speed was set at 1500 RPM, and the reaction product was detected every 30 min.

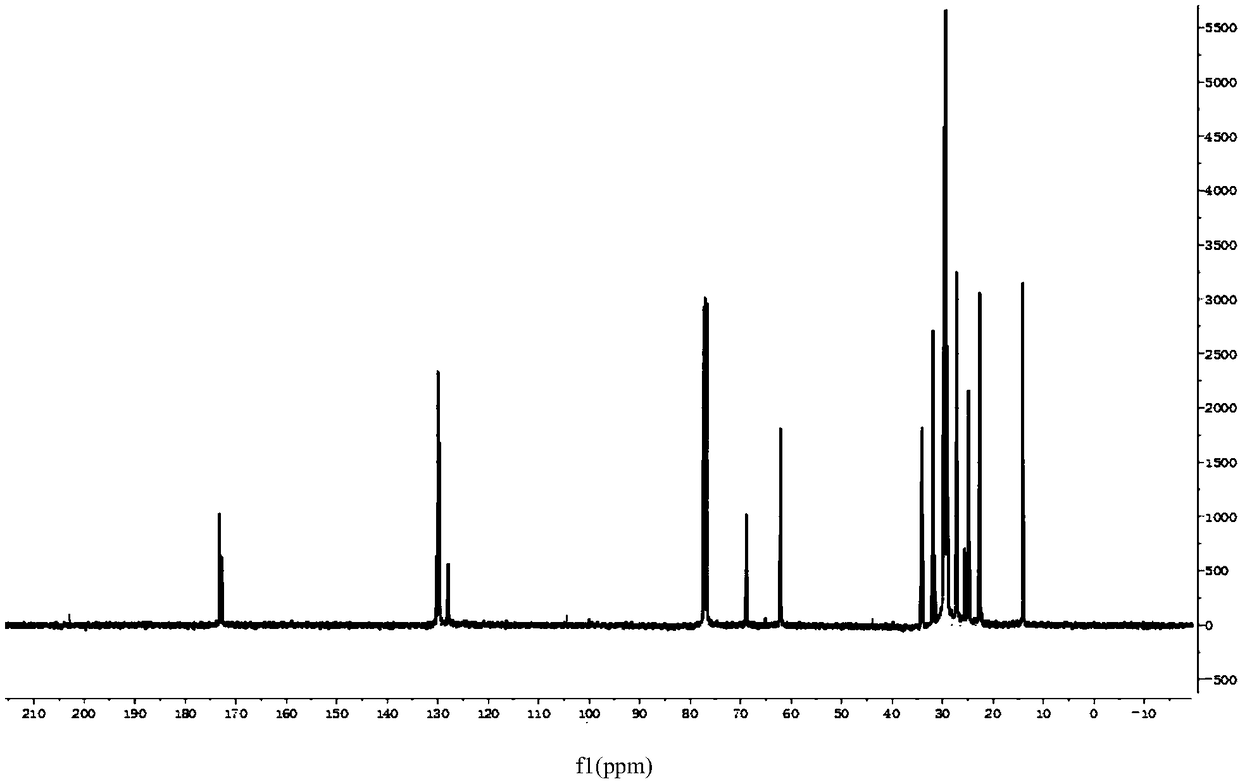

[0031] Prepare the test sample and set the test parameters: take 100 mg of the ozonation reaction product and dissolve it in 0.4 mL of deuterated chloroform (CDCl 3 ), transferred to a 5mm standard NMR tube, and Bruker 400MHz measured the carbon resonance signal of the sample ( 13 CNMR), the probe temperatur...

Embodiment 2

[0035] The reaction process is similar to Example 1, and the difference is that: a 10L reactor equipped with a mechanical stirring device is used, 5L soybean oil is added in the reactor, the controlled reaction temperature is 15°C, the power of the air source type ozone generator is 1000W, and the ozone The output is 150g / h, and the stirring speed is set at 2500RPM. 13 CNMR detection reaction time is 72h.

Embodiment 3

[0037] The reaction process is similar to Example 1, the difference is: adopt the 100L reactor of configuration mechanical stirrer, add 60L sunflower oil in the reactor, control reaction temperature to be 35 ℃, air source type ozone generator (equipped with intake air The power of the drying system) is 3000W, the ozone output is 400g / h, and the stirring speed is set at 1000RPM. 13 CNMR detection reaction time is 70h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com