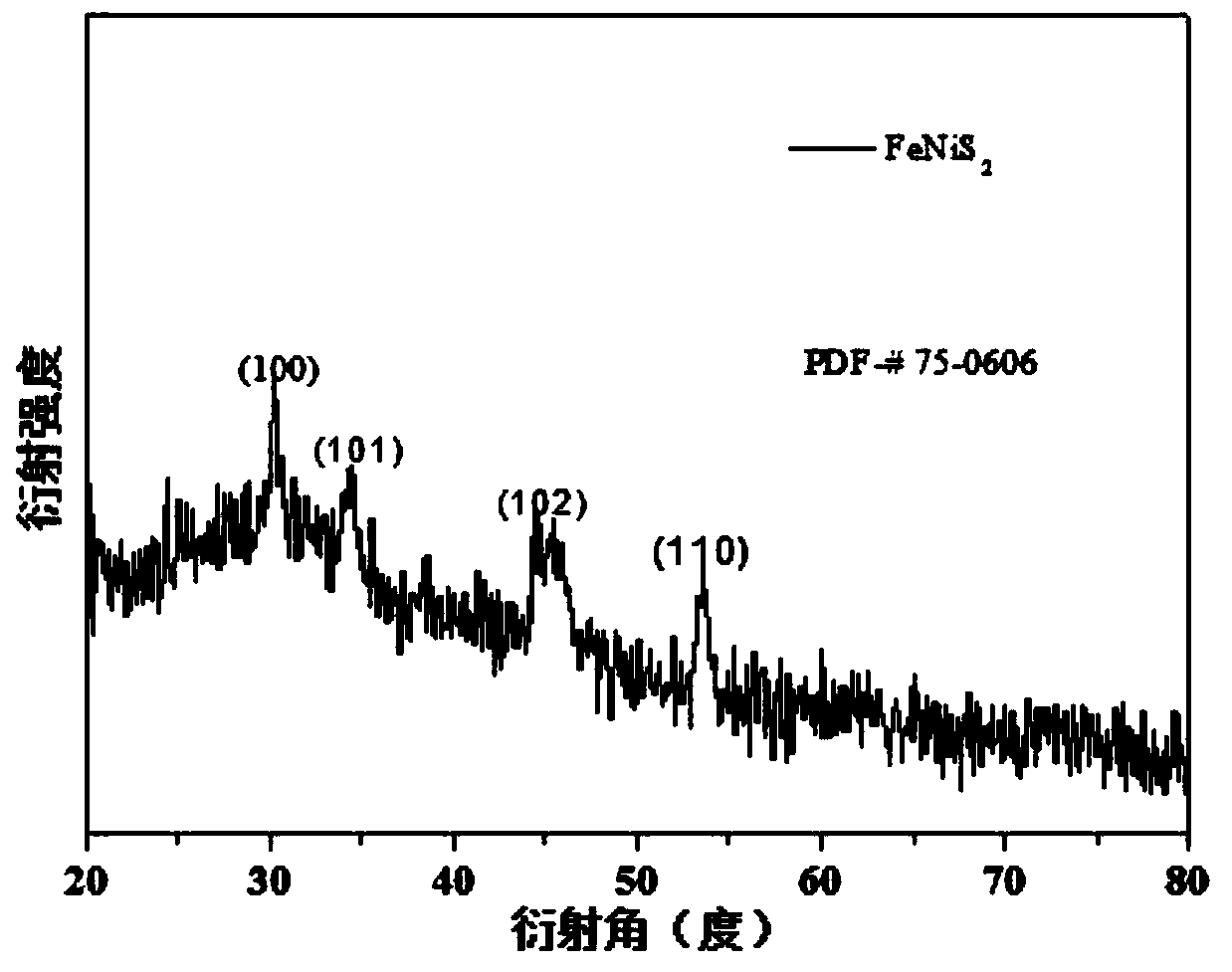

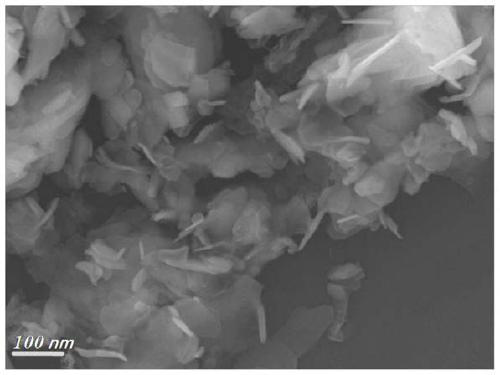

A kind of preparation method of nickel-iron sulfide/nickel foam nanocomposite electrode material

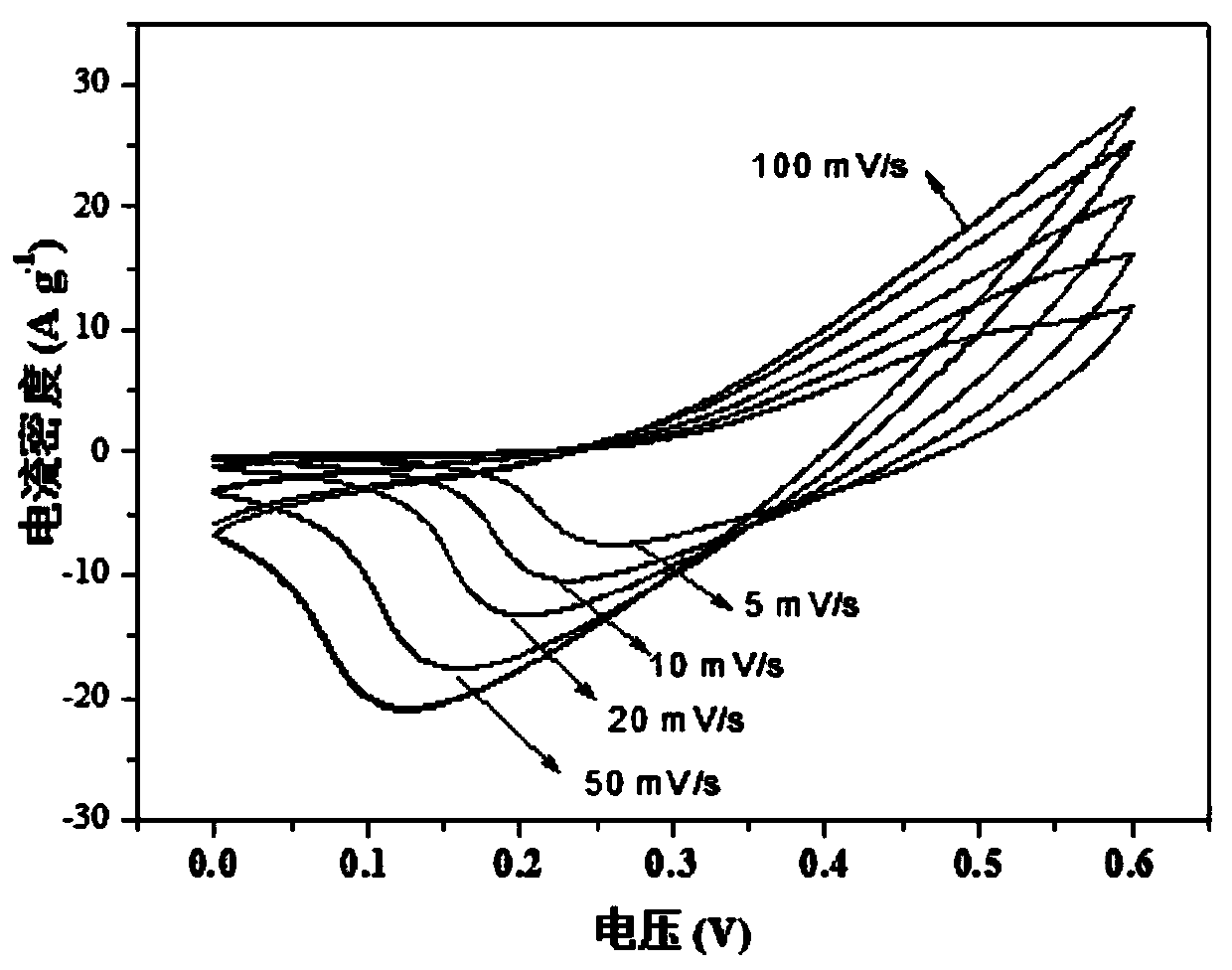

A nano-composite and electrode material technology, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., to achieve good cycle stability, improve overall capacitance performance, and high specific capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of nickel-iron sulfide / foam nickel nanocomposite electrode material, comprising the following steps:

[0029] (1) Evenly mix 5ml of ammonia water and 50ml of ethanol in a volume ratio of 1:10 and seal it for later use; soak 3cm*1cm foam nickel in 0.1mol / L HCl solution for 3 minutes, then ultrasonically clean it with deionized water and ethanol for 30 minutes, Remove the oxide film on the surface of the nickel foam, and then put it into an oven to dry for 24 hours for later use.

[0030] (2) Weigh again nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 1.0153g and iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 (0) 1.4146g, it was added in a 250ml three-necked flask, and 50ml of ethanol was added to dissolve it, while adding the nickel foam and magnet that had been processed in step (1), and magnetically stirred at 80°C under constant temperature reflux for 1 hour.

[0031] (3) Then dropwise add ammonia water to adjust the solution pH=8-10, after rea...

Embodiment 2

[0034] A preparation method of nickel-iron sulfide / foam nickel nanocomposite electrode material, comprising the following steps:

[0035] (1) Evenly mix 5ml of ammonia water and 50ml of ethanol in a volume ratio of 1:10 and seal it for later use; soak 3cm*1cm foam nickel in 0.1mol / L HCl solution for 3 minutes, then ultrasonically clean it with deionized water and ethanol for 30 minutes, Remove the oxide film on the surface of the nickel foam, and then put it into an oven to dry for 24 hours for later use.

[0036] (2) Weigh again nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 1.0153g and iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 (0) 1.4146g, it was added in a 250ml three-necked flask, and 50ml of ethanol was added to dissolve it, while adding the foamed nickel and magnet that had been processed in step (1), and magnetically stirred at constant temperature under reflux for 2 hours at 100°C.

[0037] (3) Then dropwise add ammonia water to adjust the pH of the solution=8...

Embodiment 3

[0040] A preparation method of nickel-iron sulfide / foam nickel nanocomposite electrode material, comprising the following steps:

[0041] (1) Evenly mix 5ml of ammonia water and 50ml of ethanol in a volume ratio of 1:10 and seal it for later use; soak 3cm*1cm foam nickel in 0.1mol / L HCl solution for 3 minutes, then ultrasonically clean it with deionized water and ethanol for 30 minutes, Remove the oxide film on the surface of the nickel foam, and then put it into an oven to dry for 24 hours for later use.

[0042] (2) Weigh again nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 1.0153g and iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 (0) 1.4146g, it was added in a 250ml three-necked flask, and 50ml of ethanol was added to dissolve it, while adding the nickel foam and magnetite processed in step (1), and magnetically stirred at constant temperature under reflux for 1.5 hours at 90°C.

[0043] (3) Then add ammonia water dropwise to adjust the pH of the solution to 8-10. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com