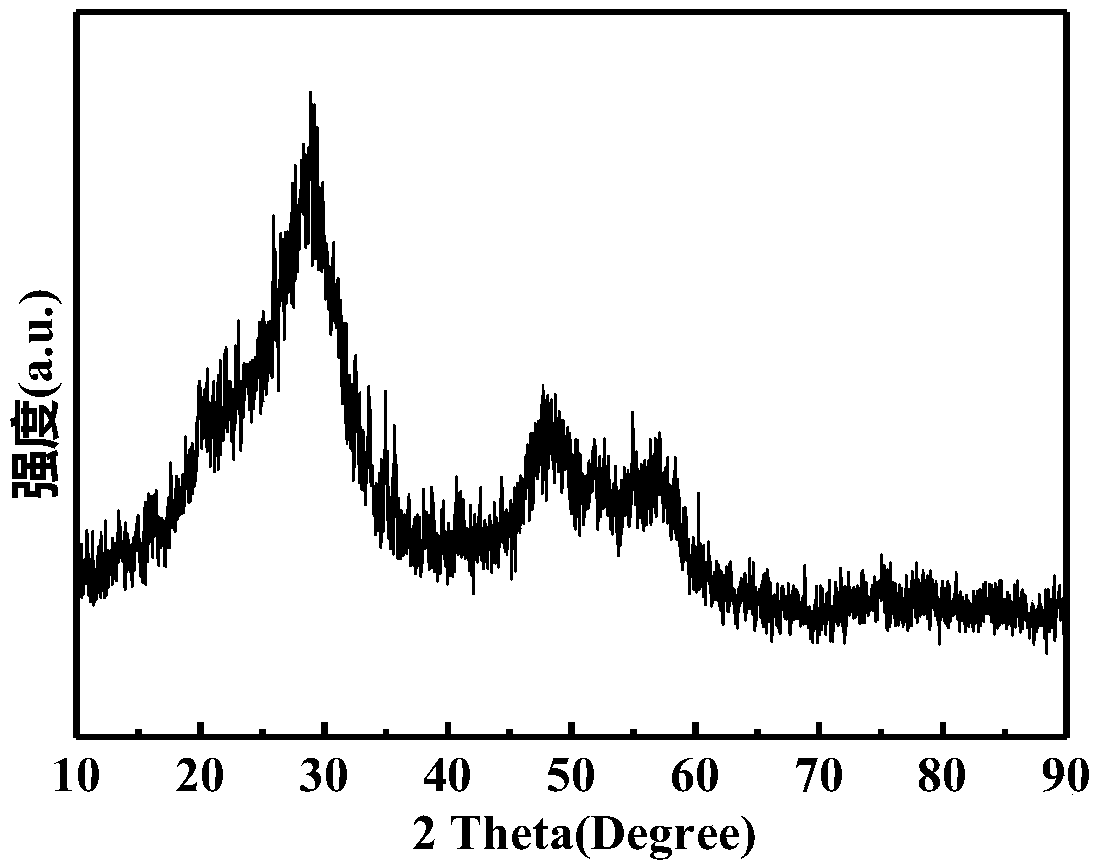

A method for preparing carbon-coated zinc sulfide-supported graphene as negative electrode of potassium ion battery

A battery negative electrode and zinc sulfide technology, applied in the field of functional nanomaterials and electrochemistry, to achieve excellent cycle performance and capacity performance, mild reaction conditions, and ultra-high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 2.43g of zinc nitrate hexahydrate and 1.578g of 2-methylimidazole in 50ml of methanol respectively to form a mixed solution, and stir magnetically for 10min. During the stirring process, the methanol solution of 2-methylimidazole was added dropwise to the methanol solution of zinc nitrate hexahydrate, after the dropwise addition was completed, the mixture was stirred vigorously for 20 minutes, and the mixture was aged at room temperature for 24 hours. After washing and drying, the polyhedral precursor ZIF-8 of zinc was obtained. Then take 30mg of ZIF-8 powder and 10ml of methanol in aqueous solution to form a mixed solution, gradually add 30mg of cysteine, 25mg of urea and 120mg of glucose, stir for a period of time, then transfer the mixed solution to a high-pressure reactor, set the temperature to 120 ℃, the time is 24 hours, after the reaction is completed, cool to room temperature and centrifuge to wash, and vacuum-dry to obtain carbon fully-coated dendriti...

Embodiment 2

[0031]Dissolve 2.43g of zinc nitrate hexahydrate and 1.578g of 2-methylimidazole in 50ml of methanol to form a mixed solution, and stir magnetically for 10min. During the stirring process, the methanol solution of 2-methylimidazole was added dropwise to the methanol solution of zinc nitrate hexahydrate, after the dropwise addition was completed, the mixture was stirred vigorously for 20 minutes, and the mixture was aged at room temperature for 24 hours. After washing and drying, the polyhedral precursor ZIF-8 of zinc was obtained. Then take 30mg of ZIF-8 powder and 10ml of methanol in aqueous solution to form a mixed solution, gradually add 30mg of cysteine, 25mg of urea and 120mg of glucose, stir for a period of time, then transfer the mixed solution to a high-pressure reactor, set the temperature to 120 ℃, the time is 12h, after the reaction is completed, cool to room temperature, centrifuge and dry, and vacuum-dry to obtain dendritic zinc sulfide microspheres fully coated w...

Embodiment 3

[0033] Dissolve 2.43g of zinc nitrate hexahydrate and 1.578g of 2-methylimidazole in 50ml of methanol to form a mixed solution, and stir magnetically for 10min. During the stirring process, the methanol solution of 2-methylimidazole was added dropwise to the methanol solution of zinc nitrate hexahydrate, after the dropwise addition was completed, the mixture was stirred vigorously for 20 minutes, and the mixture was aged at room temperature for 24 hours. After washing and drying, the polyhedral precursor ZIF-8 of zinc was obtained. Then take 30mg of ZIF-8 powder and 10ml of methanol in aqueous solution to form a mixed solution, gradually add 30mg of cysteine, 25mg of urea and 120mg of glucose, stir for a period of time, then transfer the mixed solution to a high-pressure reactor, set the temperature to 120 ℃, the time is 48h, after the reaction is completed, cool to room temperature, centrifuge and dry, and vacuum-dry to obtain carbon fully-coated dendritic zinc sulfide micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com