VOCs normal temperature degradation high efficiency catalyst, and preparation method and applications thereof

A catalyst, room temperature technology, used in heterogeneous catalyst chemical elements, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that the performance needs to be further improved, and achieve high VOCs removal. In addition to activity, high selectivity, mild use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of VOCs normal temperature degradation high-efficiency catalyst, comprising the following steps:

[0031] (1) Weigh silica sol, aluminum sol, tetrapropylammonium bromide, hexadecyltrimethylammonium bromide, and ammonia water in a molar ratio of 20:1:3:3:10 to weigh the corresponding reagents, and the silica sol , aluminum sol, tetrapropylammonium bromide, and cetyltrimethylammonium bromide were dissolved in water, and mixed uniformly to obtain solution A; ammonia water was dissolved in water to obtain solution B; after mixing solution A and solution B Transferred to a ball mill jar, ball milled for 18 hours, centrifuged at 3000 r / min, dried at 100°C for 12 hours, and calcined at 550°C for 6 hours to obtain a carrier.

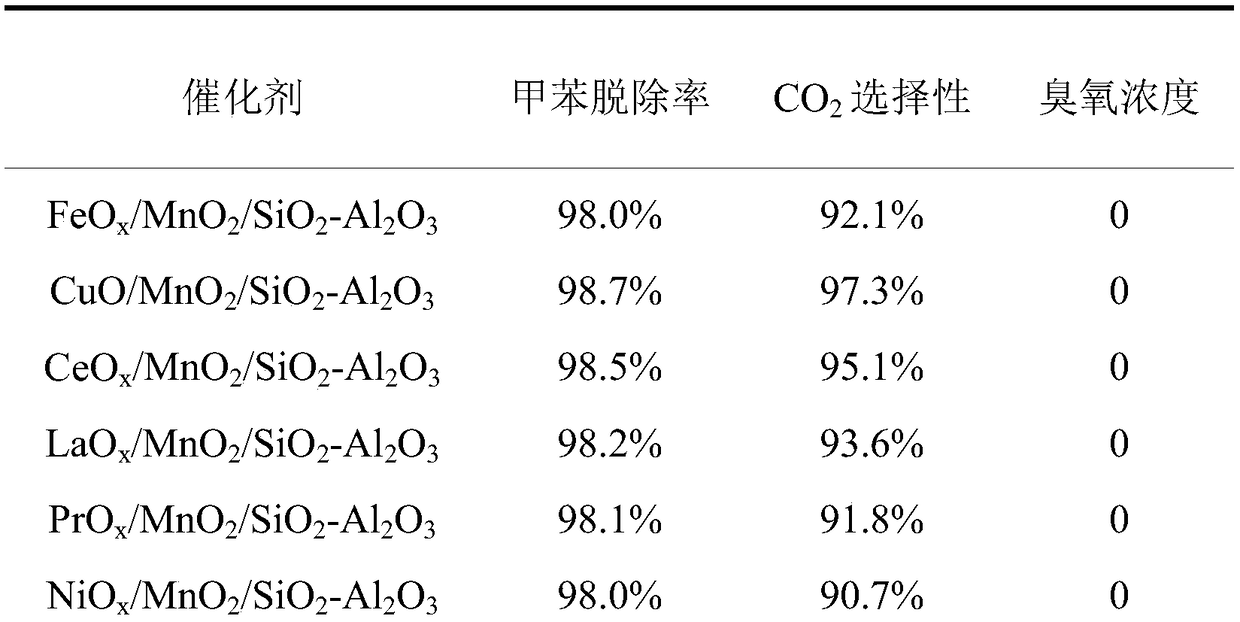

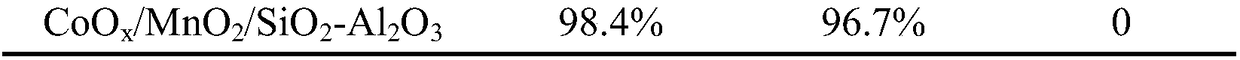

[0032] (2) Add the manganese salt solution to the carrier prepared in step (1), stir for 2h, the stirring speed is 360r / min, the MnO in the manganese salt 2 Elements accounted for SiO 2 -Al 2 o 3 The mass ratio is 5%; weigh a cert...

Embodiment 2

[0039] A preparation method of VOCs normal temperature degradation high-efficiency catalyst, comprising the following steps:

[0040] (1) Weigh silica sol, aluminum sol, tetrapropylammonium bromide, polyoxyethylene-polyoxypropylene-polyoxyethylene co-embedded polymer, and sodium hydroxide at a molar ratio of 400:1:10:10:40 Take the corresponding reagent, dissolve silica sol, aluminum sol, tetrapropylammonium bromide, polyoxyethylene-polyoxypropylene-polyoxyethylene co-embedded polymer in water, and mix well to obtain solution A; dissolve sodium hydroxide in water to obtain solution B; mix solution A and solution B, transfer to a ball mill jar, mill for 36 hours, centrifuge at 4000 r / min, dry at 100°C for 12 hours, and roast at 550°C for 6 hours to obtain a carrier.

[0041] (2) Add the manganese salt solution to the carrier prepared in step (1), stir for 6h, the stirring speed is 120r / min, MnO 2 Elements accounted for SiO 2 -Al 2 o 3 The mass ratio is 35%; weigh a certain ...

Embodiment 3

[0048] A preparation method of VOCs normal temperature degradation high-efficiency catalyst, comprising the following steps:

[0049](1) Silica sol, aluminum sol, tetrapropylammonium bromide, cetyltrimethylammonium bromide, polyoxyethylene-polyoxypropylene-polyoxyethylene co-embedded polymer, and potassium hydroxide are mixed in molar ratio Weigh the corresponding reagents at 300:1:5:5:5:30, mix silica sol, aluminum sol, hexadecyltrimethylammonium bromide, polyoxyethylene-polyoxypropylene-polyoxyethylene co-embedded polymer Dissolve in water and mix well to obtain solution A; dissolve potassium hydroxide in water to obtain solution B; mix solution A and solution B and transfer to a ball mill tank, ball mill for 24 hours, centrifuge at a speed of 2000r / min, and place at 100 °C for 12 hours, and then calcined at 550 °C for 6 hours to obtain a carrier.

[0050] (2) Add the manganese salt solution to the carrier prepared in step (1), stir for 4h, the stirring speed is 240r / min, M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com