Deodorant and preparation method thereof

A deodorant and metal technology, which is applied in the field of deodorant and its preparation, can solve the problems of poor removal effect of mercaptan or thioether compound, loss of deodorant effect of deodorant, high cost of manufacture and use, Achieve low production cost, low regeneration difficulty, and good broad-spectrum effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

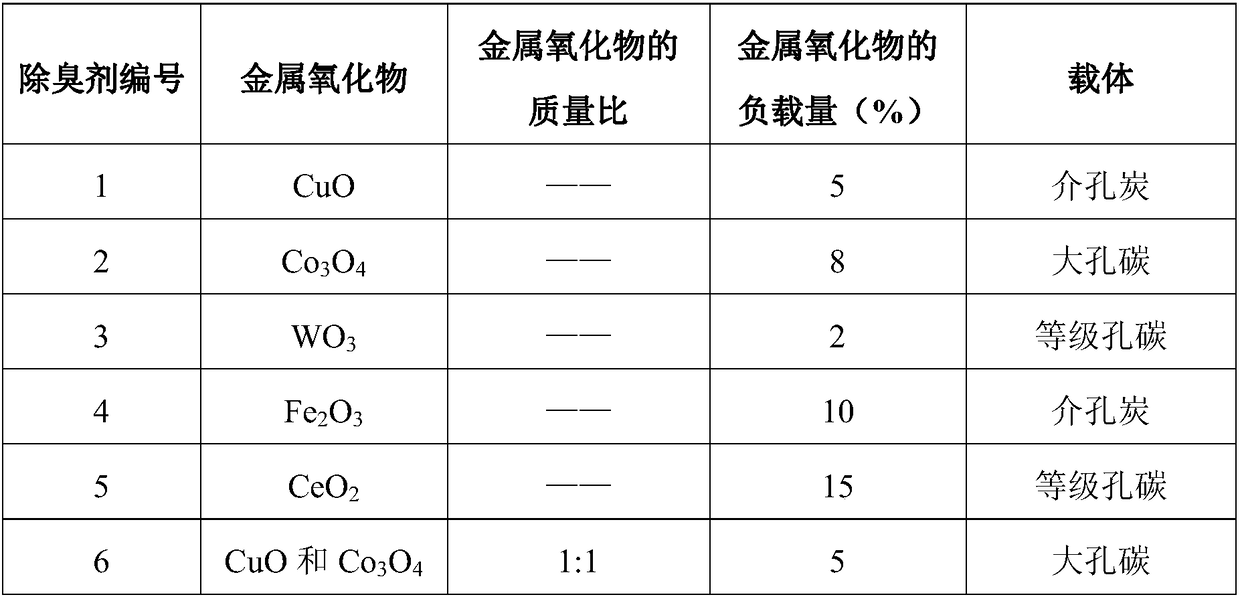

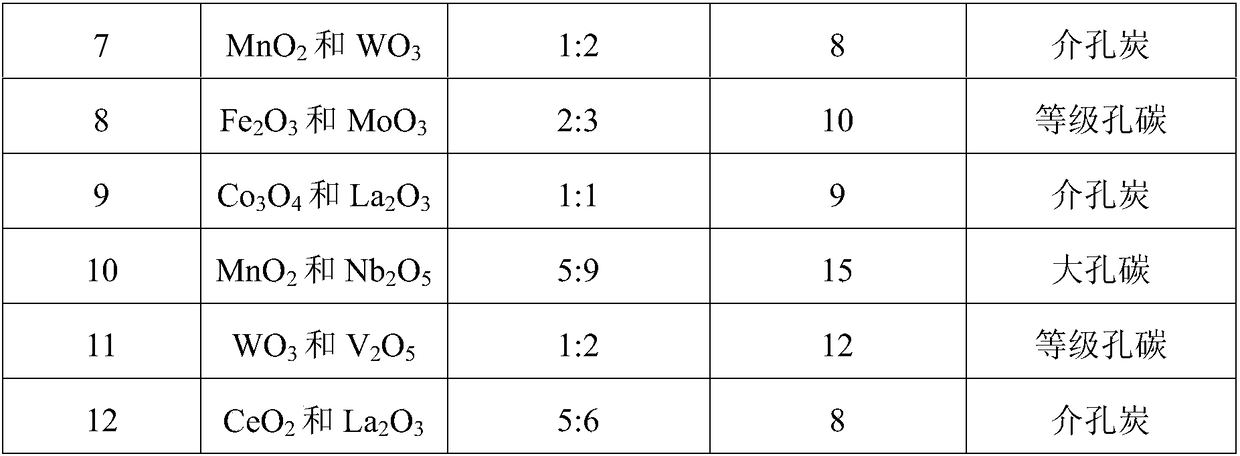

preparation example Construction

[0024] The preparation method of the above-mentioned deodorant comprises the following steps: dispersing the nitrate or acetate corresponding to the metal oxide in a solvent as a precursor, adding a carrier, ultrasonically dispersing, filtering, drying the solid product, and then placing Under protective atmosphere, bake at 300-600°C for 3-5 hours.

[0025] Preferably, the drying is carried out at 100-120° C., and the drying time is 10-15 hours.

Embodiment 1

[0028] A deodorant, its preparation method is as follows: prepare 0.35wt% copper nitrate solution, then add mesoporous carbon (calculate the addition of mesoporous carbon with the load of copper nitrate as 5wt%), ultrasonically disperse evenly, leave standstill After 12 hours, it was filtered, and the filter residue was dried at 110°C for 12 hours, then placed in a nitrogen atmosphere, and calcined at 500°C for 4 hours to obtain deodorant 1.

Embodiment 2

[0030] A kind of deodorant, its preparation method is as follows: prepare the cobalt nitrate solution of 0.1mol / L, then add macroporous carbon (calculate the addition amount of macroporous carbon with the loading capacity of copper nitrate as 8wt%), ultrasonic dispersion is even, adjust The pH value of the reaction liquid reached 11, and was centrifuged after standing for 12 hours. The solid product was dried at 120° C. for 10 hours, and then placed in a nitrogen atmosphere and roasted at 400° C. for 5 hours to obtain deodorant 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com