Preparation method of hydrodesulfurization catalyst with mesoporous carbon material as carrier

A hydrodesulfurization and catalyst technology, applied in the petrochemical field, can solve problems such as uneven distribution of eggshell catalysts, and achieve high removal activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 0.88g thiourea, 0.93g cobalt molybdenum heteropoly acid, 42.12g sodium chloride and 3.15g glucose into 200mL distilled water and stir for 30 minutes to make them fully mixed. The solution was frozen in a -80°C refrigerator, then transferred to a lyophilizer for vacuum sublimation and drying for 72 hours to obtain a light blue solid powder. The fully dried sample was placed in a high-temperature furnace, protected by nitrogen, and baked at 750°C for 3 hours; after the sample was cooled to room temperature, it was taken out and washed with a large amount of distilled water to ensure that no template remained. Finally, wash and disperse with absolute ethanol to ensure that the product will not agglomerate in large quantities. The washed samples were placed in a vacuum oven at 70°C overnight. After the sample is dried, it is fully ground and evenly obtained as the sulfided cobalt-molybdenum hydrodesulfurization catalyst 1.

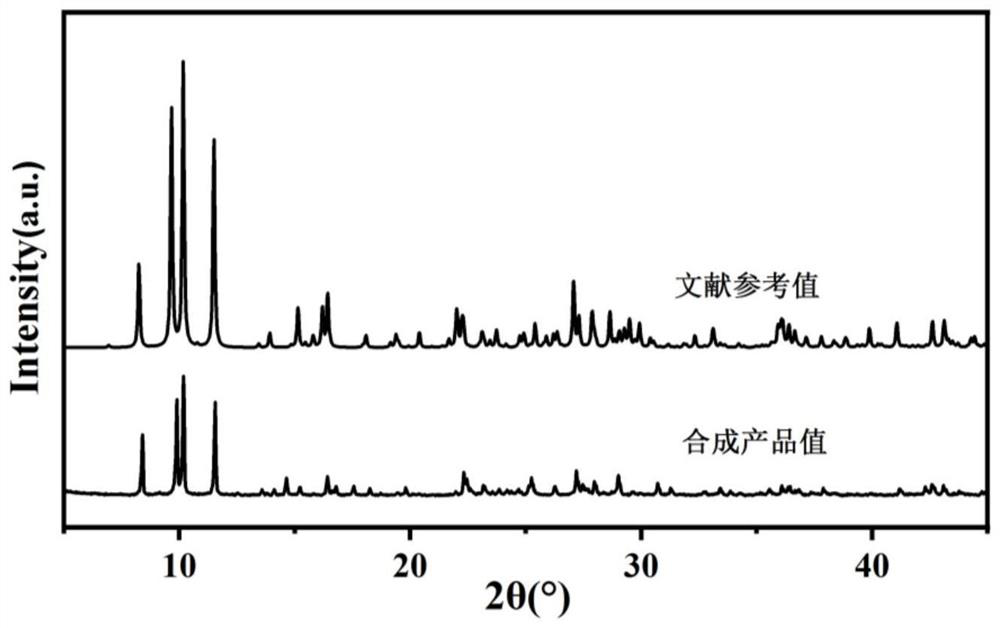

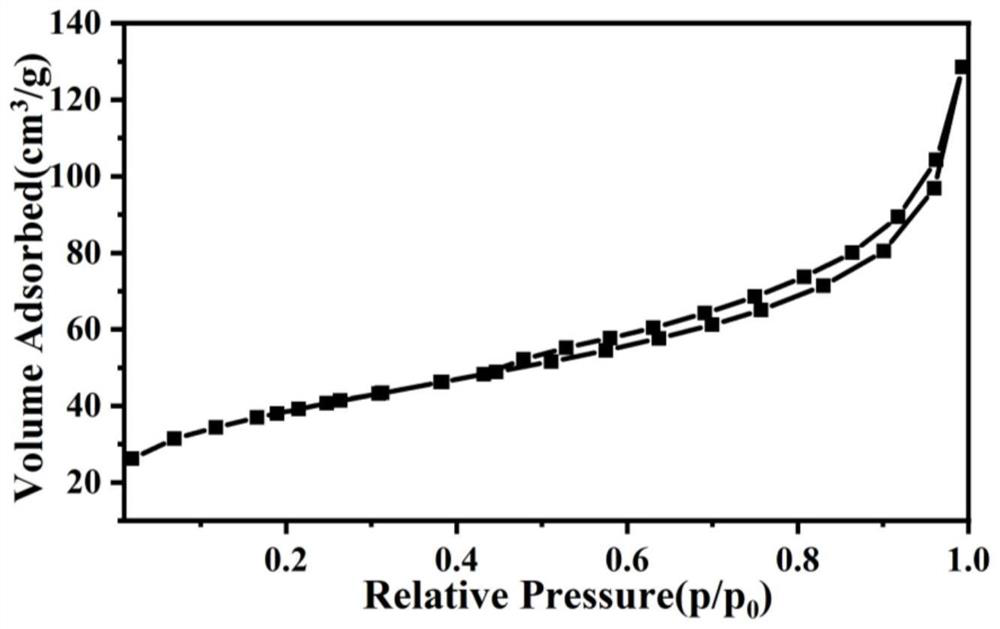

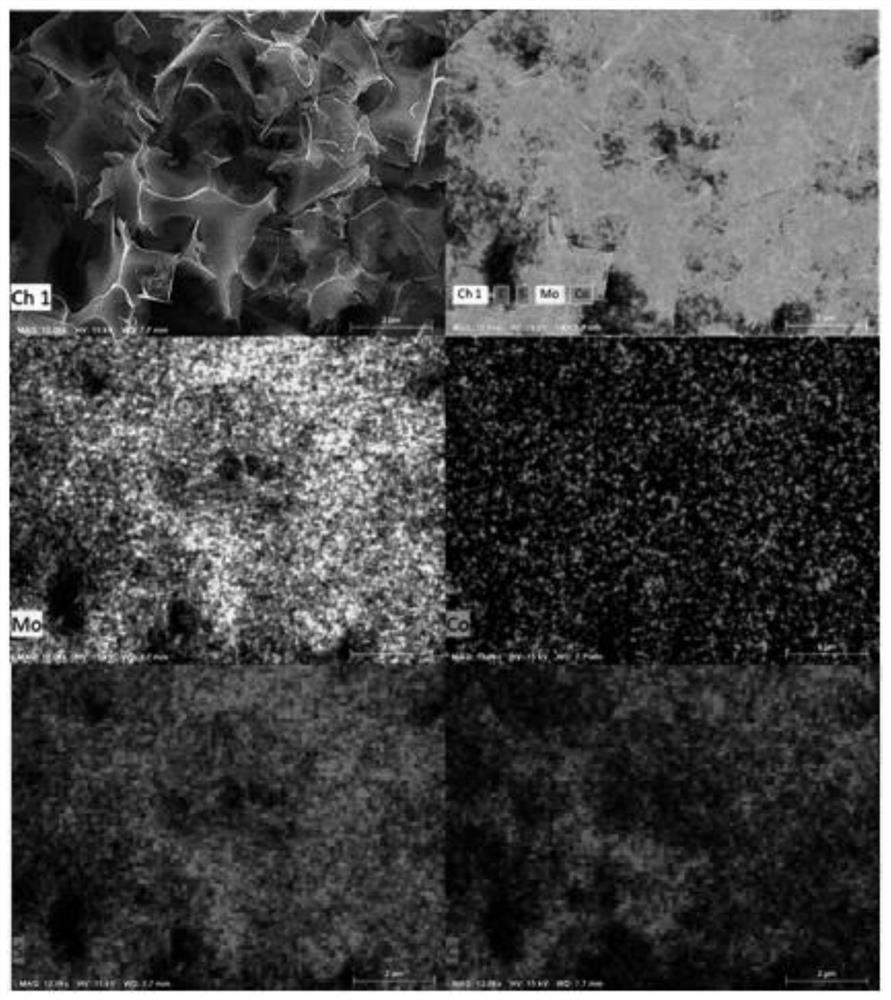

[0028] figure 1 For the cobalt-molybdenu...

Embodiment 2

[0033] The preparation process of the catalyst is the same as in Example 1, except that the molybdenum salt and cobalt salt are replaced by ammonium molybdate and cobalt nitrate in the preparation process of the catalyst precursor, and the amount of sulfurizing agent is increased. Present embodiment catalyst preparation method is as follows:

[0034] Weigh 0.88g of thiourea, 0.95g of ammonium molybdate, 0.78g of cobalt nitrate, 42.12g of sodium chloride and 3.15g of glucose into 200mL of distilled water and stir for 30 minutes to fully mix them evenly. The solution was frozen in a -80°C refrigerator, then transferred to a lyophilizer for vacuum sublimation and drying for 72 hours to obtain a light blue solid powder. The fully dried sample was placed in a high-temperature furnace, protected by nitrogen, and baked at 750°C for 3 hours; after the sample was cooled to room temperature, it was taken out and washed with a large amount of distilled water to ensure that no template re...

Embodiment 3

[0036] The preparation process of the catalyst is the same as in Example 1, except that the template agent used to prepare the catalyst precursor is potassium chloride, and the carbon source is citric acid. Present embodiment catalyst preparation method is as follows:

[0037] Weigh 0.88g thiourea, 0.93g cobalt-molybdenum heteropolyacid, 38.25g potassium chloride and 3.36g citric acid respectively and add them into 200mL distilled water and stir for 30 minutes to make them fully mixed. The solution was frozen in a -80°C refrigerator, then transferred to a lyophilizer for vacuum sublimation and drying for 72 hours to obtain a light blue solid powder. The fully dried sample was placed in a high-temperature furnace, protected by nitrogen, and baked at 750°C for 3 hours; after the sample was cooled to room temperature, it was taken out and washed with a large amount of distilled water to ensure that no template remained. Finally, wash and disperse with absolute ethanol to ensure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com