Preparation method and application of zirconium carbonate salt

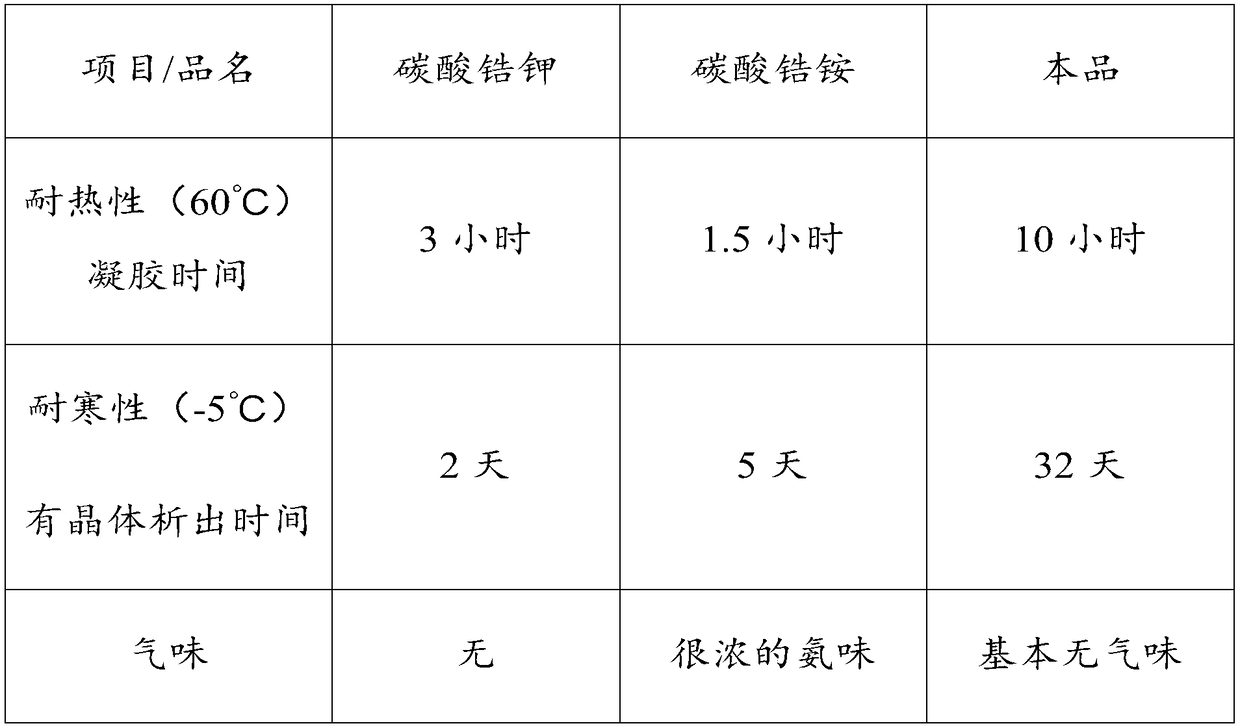

A technology of zirconium carbonate and potassium carbonate is applied in the field of preparation of zirconium carbonate, which can solve the problems of ammonium zirconium carbonate crosslinking agent having strong ammonia smell, poor storage stability and high cost, achieves a simple and feasible preparation method, and improves heat and cold resistance. performance, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 100g of deionized water to the reaction vessel with stirrer, condenser and thermometer, start stirring, add 3.5g of tartaric acid, stir for 10 minutes until it is completely dissolved, add 60g of potassium bicarbonate, stir for 5 minutes, add 10g of bicarbonate Ammonium, stir until it is completely dissolved, slowly add 50g of zirconium carbonate, heat up to 60°C and react for 0.5 hours until it is completely clear, cool down to a material temperature below 40°C, add 25g of ammonium chloride, react at 40°C for 30 minutes, and filter. This product.

Embodiment 2

[0043] Add deionized water 100g in the reaction vessel with agitator, condenser and thermometer, start stirring, add tartaric acid 3.5g, stir 10 minutes until it dissolves completely, add 80g potassium carbonate, stir 5 minutes, add 25g ammonium carbonate, Stir until completely dissolved, slowly add 50g of zirconium hydroxide, heat up to 60°C and react for 0.5 hours until completely clear, cool down to a material temperature below 40°C, add 20g of ammonium chloride, react at 40°C for 30 minutes, and filter. Taste.

Embodiment 3

[0045] The difference between this embodiment and embodiment 1 is:

[0046] The addition amount of water-soluble weak base salt, stabilizer, zirconium compound and ripening accelerator accounts for 20wt%, 1.5wt%, 25wt% and 6wt% of the total reaction system respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com