Nanoscale admixture for wet shotcrete and its application method

A wet sprayed concrete, nano-scale technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc. And silica fume loose bulk density and particle dispersion, no mention of the rebound rate of wet sprayed concrete, etc., to achieve the overall construction efficiency improvement, final setting time shortening, and the effect of reducing comprehensive construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

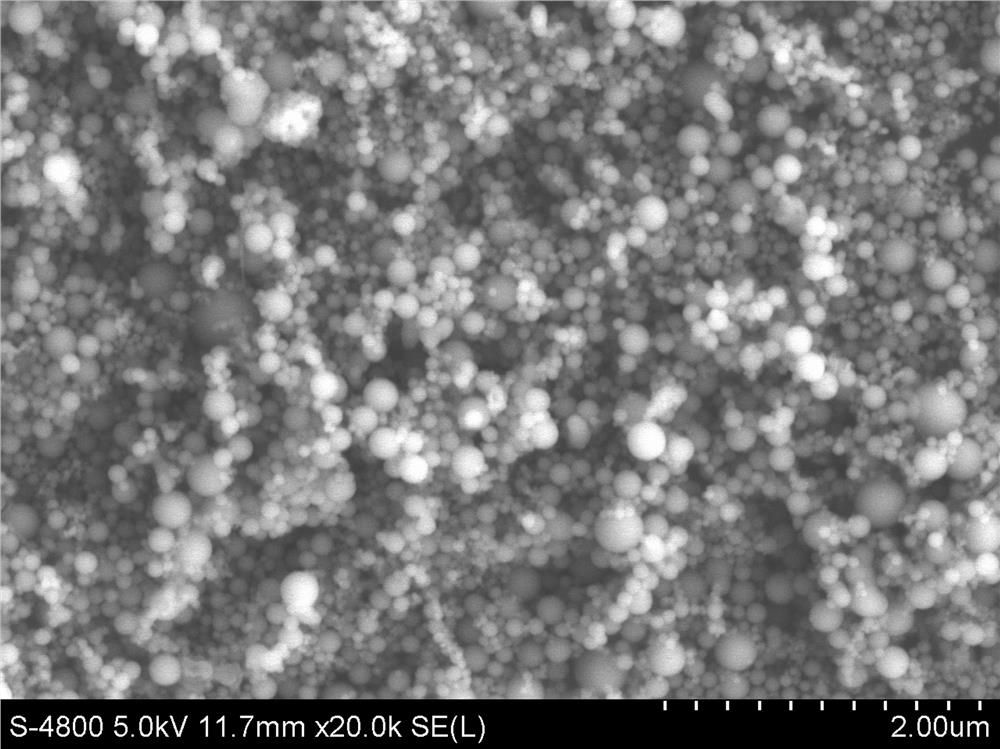

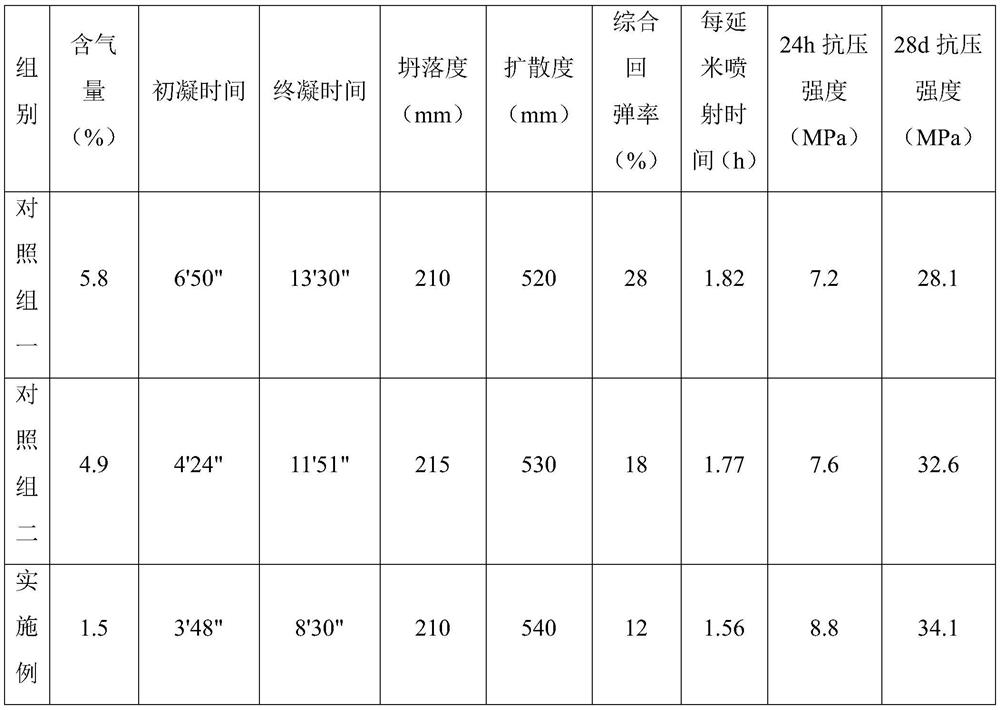

[0074] A nanoscale admixture for wet sprayed concrete, comprising the following components in weight percent: SiO 2 Content 80%, bulk density 400kg / m 3 98.5% of silica fume, 4.8% of 80μm sieve, and 1.5% of powdered polycarboxylate high-performance water reducer with a water reducing rate of 25% and an air content of 2.0% tested in accordance with the GB 8076 "Concrete Admixtures" standard.

[0075] Except that no water reducer was added, the other raw materials used in the wet shotcrete were the same as those in the control group 1.

[0076] The concrete mix ratio used is P.O42.5 ordinary Portland cement: sand: pea stone: the admixture: water: low-alkali liquid quick-setting agent = 405:860:860:45:180:18.

[0077] The preparation process of wet sprayed concrete is as follows: in a twin-shaft forced mixer, first mix the nanoscale admixture and coarse aggregate evenly for 30 seconds, then add cement, sand, and water, and mix evenly.

[0078] With a rated capacity of 5m 3 / h T...

Embodiment 2

[0081] A nanoscale admixture for wet sprayed concrete, comprising the following components in weight percent: SiO 2 Content 80%, bulk density 400kg / m 3 Silica fume 96.8%, 80μm sieve 4.8%, and according to GB 8076 "Concrete Admixtures" standard detection of water reducing rate of 30%, air content of 2.0% powdered polycarboxylate high-performance water reducer 2.5%, citric acid Sodium 0.7%.

[0082] Except that no water reducer was added, the other raw materials used in the wet shotcrete were the same as those in the control group 1.

[0083] The mix ratio and preparation process of the wet shotcrete used are the same as those in Example 1.

[0084] With a rated capacity of 5m 3 / h TK-500 wet spraying machine construction, test the comprehensive rebound rate of spraying on a section of 3m long, 5m high Class III surrounding rock, and a horseshoe-shaped cave side arch with steel hanging nets, and take the largest Plate test core sample compressive strength.

[0085] The prop...

Embodiment 3

[0087] A nanoscale admixture for wet sprayed concrete, comprising the following components in weight percent: SiO 2 Content 90%, bulk density 400kg / m 3 Silica fume 98.45%, 80μm sieve 4.8%, and according to GB 8076 "Concrete Admixtures" standard detection of water reducing rate of 30%, air content of 2.0% powdered polycarboxylate high-performance water reducing agent 1.5%, 100,000 Molecular weight cellulose ether 0.05%.

[0088] Except that no water reducer was added, the other raw materials used in the wet shotcrete were the same as those in the control group 1.

[0089] The mix ratio and preparation process of the wet shotcrete used are the same as those in Example 1.

[0090] With a rated capacity of 5m 3 / h TK-500 wet spraying machine construction, test the comprehensive rebound rate of spraying on a section of 3m long, 5m high Class III surrounding rock, and a horseshoe-shaped cave side arch with steel hanging nets, and take the largest Plate test core sample compressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com