LLDPE and TPE composite cable material and preparation method thereof

A composite cable and nano-carbon material technology, applied in the field of LLDPE and TPE composite cable materials and their preparation, can solve the problems of poor mechanical properties and oxidation resistance, reduce the rate of autoxidation reaction, improve mechanical and electrical properties, Good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

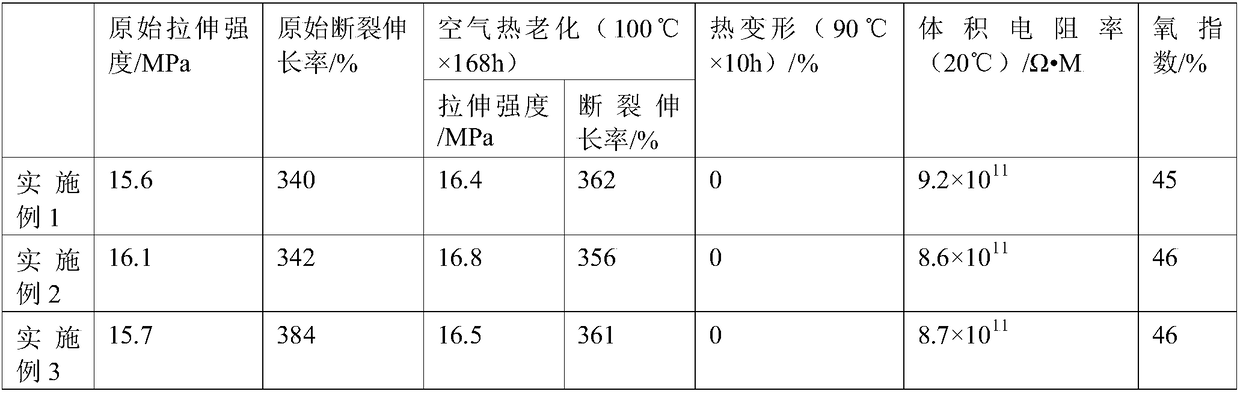

Examples

Embodiment 1

[0025] A composite cable material of LLDPE and TPE, comprising 80 parts of linear low-density polyethylene, 30 parts of thermoplastic elastomer, 18 parts of polyphenylene ether resin, 3 parts of ethyl methacrylate, and 5 parts of epoxy soybean oil in parts by weight , 10 parts of pentaerythritol oleate, 8 parts of chlorinated paraffin, 3 parts of modified magnesium aluminum hydrotalcite, 2 parts of zinc borate, 10 parts of smoke suppressant, 4 parts of heat stabilizer, 0.5 part of lubricant, 8 parts of filler, compound 1 part of antioxidant, 1 part of nano-carbon material, the composite antioxidant includes 75 parts of antioxidant 300, 15 parts of antioxidant 1010, 3 parts of VE, 2 parts of rare earth oxides, 10 parts of white carbon black.

[0026] The linear low density polyethylene adopts LL1002KW of ExxonMobil of Saudi Arabia; thermoplastic elastomer, MFR is 1g / 10min, Suzhou Hongshuo Elastomer Technology Co., Ltd. The polyphenylene ether adopts PPO540V from Asahi Kasei, J...

Embodiment 2

[0033] A composite cable material of LLDPE and TPE, comprising 90 parts of linear low-density polyethylene, 25 parts of thermoplastic elastomer, 20 parts of polyphenylene ether resin, 4 parts of ethyl methacrylate, and 4 parts of epoxy soybean oil in parts by weight , 13 parts of pentaerythritol oleate, 6 parts of chlorinated paraffin, 5 parts of modified magnesium aluminum hydrotalcite, 2 parts of zinc borate, 9 parts of smoke suppressant, 3 parts of heat stabilizer, 0.8 part of lubricant, 9 parts of filler, compound 2 parts of antioxidant, 2 parts of nano-carbon material, the composite antioxidant includes 75 parts of antioxidant 300, 15 parts of antioxidant 1010, 3 parts of VE, 2 parts of rare earth oxide, 10 parts of white carbon black.

[0034] The linear low-density polyethylene adopts LL1002KW of Saudi Exxon Mobil, thermoplastic elastomer, MFR is 1g / 10min, Suzhou Hongshuo Elastomer Technology Co., Ltd. The polyphenylene ether adopts PPO540V from Asahi Kasei, Japan. La...

Embodiment 3

[0041] A composite cable material of LLDPE and TPE, comprising 100 parts of linear low-density polyethylene, 20 parts of thermoplastic elastomer, 10 parts of polyphenylene ether resin, 5 parts of ethyl methacrylate, and 3 parts of epoxy soybean oil in parts by weight , 15 parts of pentaerythritol oleate, 5 parts of chlorinated paraffin, 8 parts of modified magnesium aluminum hydrotalcite, 1 part of zinc borate, 8 parts of smoke suppressant, 5 parts of heat stabilizer, 1 part of lubricant, 10 parts of filler, compound 2 parts of antioxidant, 3 parts of nano-carbon material, the composite antioxidant includes 75 parts of antioxidant 300, 15 parts of antioxidant 1010, 3 parts of VE, 2 parts of rare earth oxide, 10 parts of white carbon black.

[0042] The linear low density polyethylene adopts LL1002KW of ExxonMobil of Saudi Arabia; thermoplastic elastomer, MFR is 1g / 10min, Suzhou Hongshuo Elastomer Technology Co., Ltd. The polyphenylene ether adopts PPO540V from Asahi Kasei, Ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com