Regulation and preparation method and application of multicolor fluorescent carbon dots

A technology of fluorescent carbon dots and carbon dots, which is applied in the field of preparation and application of fluorescent carbon dots, can solve the problems of cumbersome, time-consuming methods, and limit practical applications, and achieve the goals of expanded application, simple operation steps, good solubility and dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

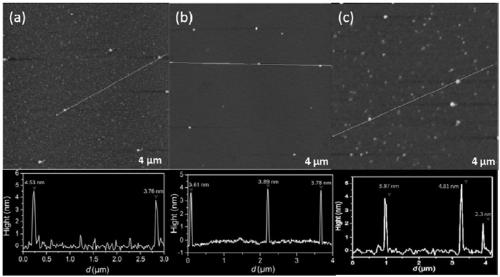

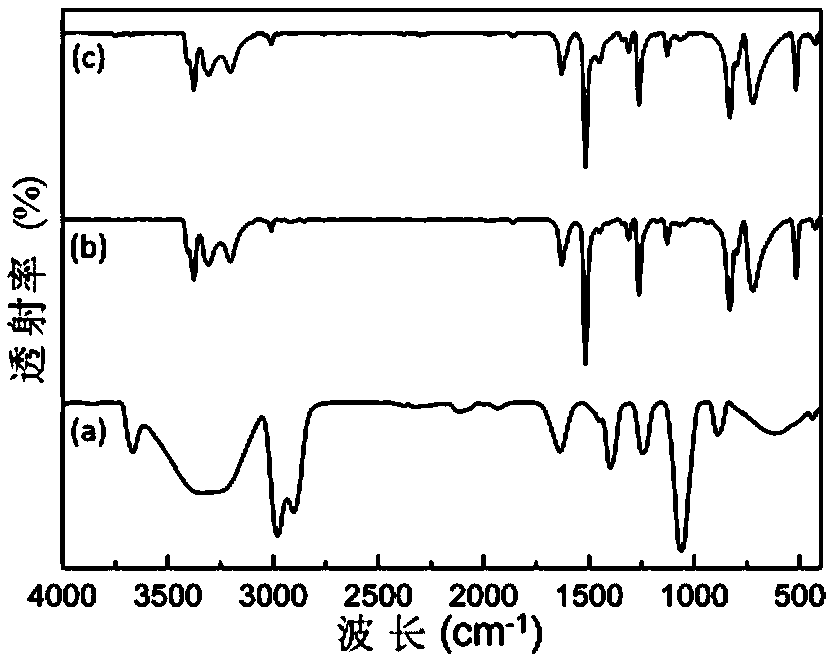

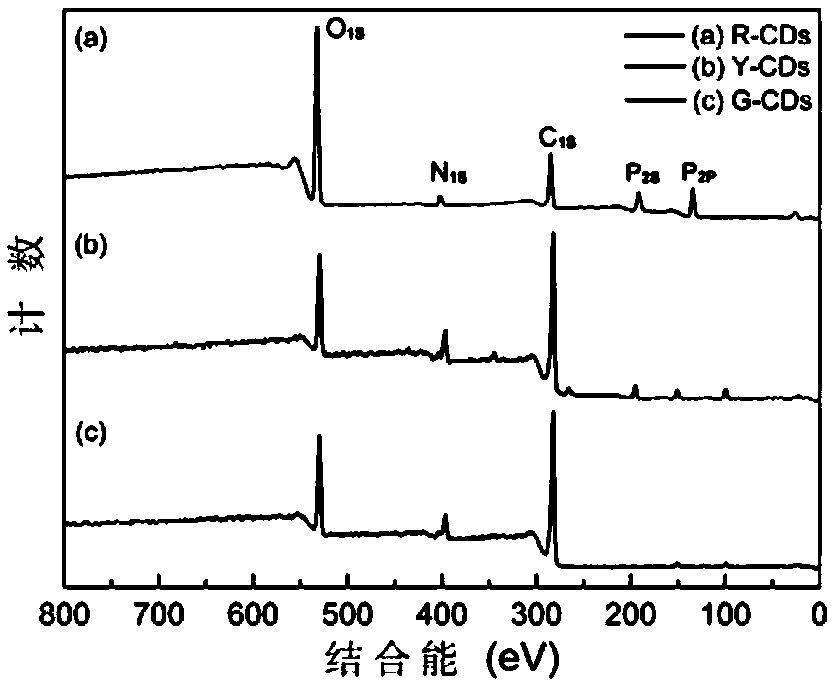

[0022] 1) Weighing 0.3 g of p-phenylenediamine and dissolving it in secondary water, then adding sulfuric acid to the solution to adjust the pH of the solution to 4, and ultrasonically obtaining a uniformly mixed solution;

[0023] 2) Transfer the above solution to a 50mL hydrothermal reaction kettle, react at 200°C for 10h, wait for the reaction to stop and let it cool down to room temperature, centrifuge to remove insoluble matter and take the supernatant, pass through a dialysis bag of 500-1000Da, in Dialysis treatment in a glass container for at least three days to obtain a pure aqueous solution of carbon dots;

[0024] 3) The above carbon dot aqueous solution was freeze-dried to obtain dark red carbon dots. Its relative quantum yield (based on rhodamine B) is 12.5%, and it exhibits red fluorescence (R-CDs).

Embodiment 2

[0026] 1) Weigh 0.3g of p-phenylenediamine and dissolve it in 20mL of secondary water, then add a small amount of HCl to the solution to adjust the pH of the solution to 3, and ultrasonically obtain a uniformly mixed solution;

[0027] 2) Transfer the above solution to a 50mL hydrothermal reaction kettle, react at 200°C for 8h, let it stand and cool to room temperature after the reaction stops, centrifuge to remove insoluble matter and take the supernatant, pass it through a 500-1000Da dialysis bag, Dialysis treatment in a glass container for at least three days to obtain a pure aqueous solution of carbon dots;

[0028] 3) The above aqueous solution of carbon dots was freeze-dried to obtain purple powdery carbon dots. Its relative quantum yield (based on rhodamine B) is 10.8%, showing orange-red fluorescence.

Embodiment 3

[0030] 1) Weigh 0.3g of p-phenylenediamine and dissolve it in secondary water, without any acid-base treatment, and ultrasonically obtain a uniform mixed solution;

[0031] 2) Transfer the above solution to a 50mL hydrothermal reaction kettle, react at 200°C for 10h, wait for the reaction to stop and let it cool down to room temperature, centrifuge to remove insoluble matter and take the supernatant, pass through a dialysis bag of 500-1000Da, in Dialysis treatment in a glass container for at least three days to obtain a pure aqueous solution of carbon dots;

[0032] 3) The above aqueous solution of carbon dots was freeze-dried to obtain purple powdery carbon dots. Its relative quantum yield (based on rhodamine B) is 7.4%, showing yellow fluorescence (Y-CDs).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com