Preparation method and application of nitrogen-doped carbon quantum dots

A technology of carbon quantum dots and nitrogen doping, applied in chemical instruments and methods, water treatment of special compounds, water/sludge/sewage treatment, etc. To achieve the effect of rich carbon source, uniform size distribution and stable fluorescence due to the lack of active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Put sucrose and ethanolamine in a glass container, add water three times, fully stir, and ultrasonically obtain a clear solution. The sum of the three times of water addition is such that the mass concentration of sucrose is 60g / L, and the mass concentration of sucrose and ethanolamine is 60g / L. The volume ratio is 1.5g:1.5ml;

[0037] 2) Put the clear solution obtained in step 1) into the liner of a polytetrafluoroethylene hydrothermal kettle, and react at 200° C. for 5 hours to obtain a reaction solution;

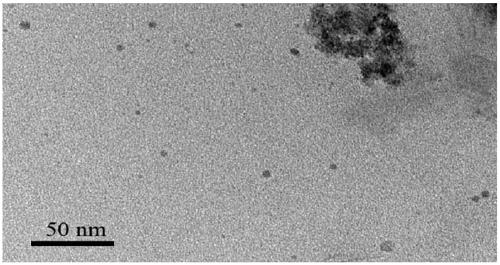

[0038] 3) Cool the reaction solution obtained in step 2) to room temperature, and filter it with a Buchner funnel. The filter paper is a medium-speed qualitative filter paper, centrifuged at a speed of 10000r / min for 10min, and filtered twice with a filter membrane with a pore size of 0.22 μm. , using a dialysis bag with a cut-off molecular weight of 1000, dialyzed for 24 hours to obtain a dialysate;

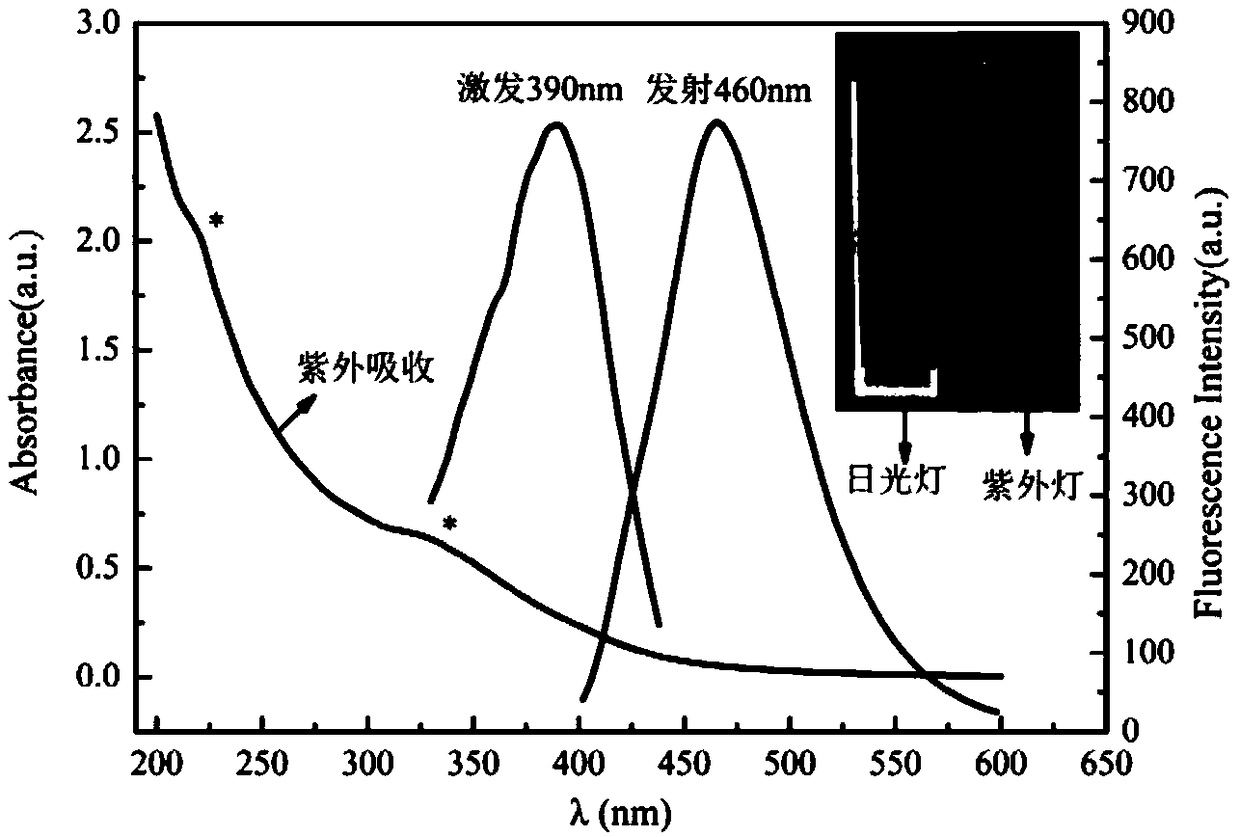

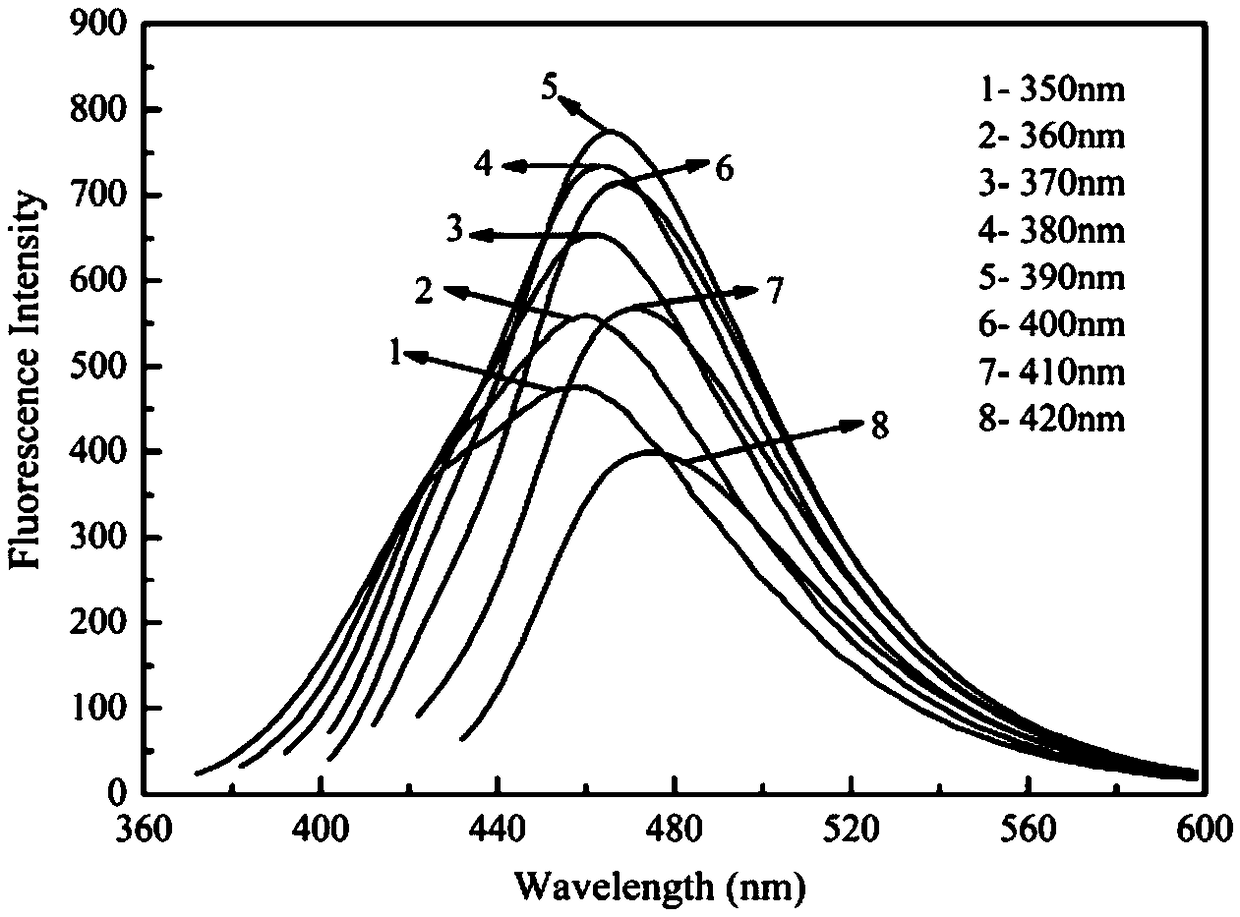

[0039] 4) Concentrate the dialysate obtained in step 3) wit...

Embodiment 2

[0047] 1) Put sucrose and ethanolamine in a glass container, add water three times, fully stir, and ultrasonically obtain a clear solution. The sum of the three times of water addition is such that the mass concentration of sucrose is 60g / L, and the mass concentration of sucrose and ethanolamine is 60g / L. The volume ratio is 1.5g:0.3ml;

[0048] All the other steps are the same as in Example 1, and its relative quantum yield (taking quinine sulfate as a standard) is 15.5%.

Embodiment 3

[0050] 1) Put sucrose and ethanolamine in a glass container, add water three times, fully stir, and ultrasonically obtain a clear solution. The sum of the three times of water addition is such that the mass concentration of sucrose is 60g / L, and the mass concentration of sucrose and ethanolamine is 60g / L. The volume ratio is 1.5g:0.9ml;

[0051] All the other steps are the same as in Example 1, and its relative quantum yield (taking quinine sulfate as a standard) is 16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com