Method for preparing high-temperature wear-resistant alumina-ceramic based composite coating

A technology of alumina ceramics and composite coatings, applied in coatings, metal material coating processes, molten spraying, etc., can solve the problems of easy expansion and cracks, etc., and achieve low preparation costs, simple operation process, The effect of low operator requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

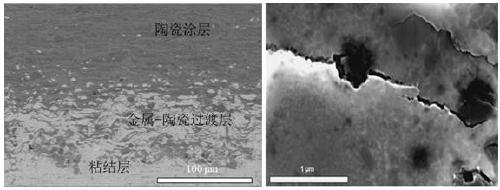

Image

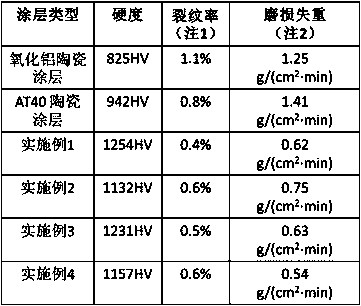

Examples

Embodiment 1

[0023] The raw materials and parts by weight used in the method described in this embodiment are: 55 parts by weight of a stabilizer, 30 parts by weight of a binder, and 15 parts by weight of a reinforcing agent, wherein the stabilizer is AT40, the binder is Al, and the reinforcing agent is zirconia.

[0024] In this embodiment, the preparation and application method of thermal spraying high-temperature wear-resistant alumina ceramic matrix composite coating is based on aluminum alloy, and the specific method is as follows:

[0025] (1) The surface of the substrate is roughened by sandblasting, and then the sandblasting surface is cleaned with dry air. The sand material used in the rough sandblasting process is zirconium corundum with a particle size of 15-30 μm.

[0026] (2) Weigh 55g AT40, 30g Al, and 15g zirconia, crush the materials by mechanical ball milling, and pass through a 325-mesh mechanical vibrating sieve.

[0027] (3) Fully mix 55g AT40 and 15g zirconia powder pr...

Embodiment 2

[0030] The raw materials and parts by weight used in the method described in this embodiment are: 80 parts by weight of a stabilizer, 17 parts by weight of a binder, and 3 parts by weight of a reinforcing agent, wherein the stabilizer is alumina, the binder is Cu, and the reinforcing agent is YSZ.

[0031] The preparation and application method of thermal spraying high-temperature wear-resistant alumina ceramic matrix composite coating in this embodiment uses copper alloy as the substrate, and the specific method is as follows:

[0032] (1) The surface of the substrate is roughened by sandblasting, and then the sandblasting surface is cleaned with dry air. The sand material used in the rough sandblasting process is zirconium corundum with a particle size of 15-30 μm.

[0033] (2) Weigh 80g of alumina, 3g of YSZ, and 17g of Cu, crush the materials by mechanical ball milling, and pass through a 325-mesh mechanical vibrating sieve.

[0034] (3) Fully mix 80g of alumina and 3g of ...

Embodiment 3

[0037] The raw materials and parts by weight used in the method described in this embodiment are: 70 parts by weight of a stabilizer, 20 parts by weight of a binder, and 10 parts by weight of a reinforcing agent, wherein the stabilizer is AT40, the binder is NiAl, and the reinforcing agent is boron carbide.

[0038] The preparation and application method of thermal spraying high-temperature wear-resistant alumina ceramic-based composite coating in this embodiment uses cast iron as the substrate, and the specific method is as follows:

[0039] (1) The surface of the substrate is roughened by sandblasting, and then the sandblasting surface is cleaned with dry air. The sand material used in the rough sandblasting process is zirconium corundum with a particle size of 15-30 μm.

[0040] (2) Weigh 70g of AT40, 20g of NiAl, and 10g of boron carbide, crush the materials by mechanical ball milling, and pass through a 325-mesh mechanical vibrating sieve.

[0041] (3) Fully mix 70g of AT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com